Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2017

Table of contents

- Executive summary

- 1 Background

- 2 Report overview

-

3 Regulatory program for the use of nuclear substances

- 3.1 CNSC regulatory effort

- 3.2 Licensing

- 3.3 Certification of prescribed equipment

- 3.4 Certification of exposure device operators

- 3.5 Certification of Class II radiation safety officers

- 3.6 RSO appointment for nuclear substances and radiation devices licences

- 3.7 RSO appointment for waste nuclear substance licences

- 3.8 Licensing and certification decisions

- 3.9 Compliance verification and enforcement

- 3.10 Stakeholder engagement

- 3.11 International commitments

- 4 Regulatory developments

- 5 Safety performance – all sectors combined

- 6 Medical sector

- 7 Industrial sector

- 8 Academic and research sector

- 9 Commercial sector

- 10 Waste nuclear substance sector

- 11 Conclusion

- Appendix A: Radiation exposure

- Appendix B: Enforcement actions issued in 2017

- Appendix C: List of reported events in 2017

- Appendix D: Inspections conducted in 2017

- Appendix E: Compliance rating levels

- Appendix F: Grading inspections

- Appendix G: Relevant Regulatory References

Executive summary

The Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2017 summarizes the safety performance of 1,590 licensees, which hold a total of 2,191 licences, and which are authorized by the Canadian Nuclear Safety Commission (CNSC) for the use of nuclear substances and prescribed equipment in the medical, industrial, academic and research, commercial, and waste nuclear substance sectors. This is the first time the waste nuclear substance licensees have been included in this regulatory oversight report.

The CNSC regulates the nuclear industry in Canada through a comprehensive program of licensing, certification, compliance verification, enforcement and reporting. For each sector described in this report, CNSC staff evaluate safety performance through inspections, assessments, and reviews of licensee programs and processes.

CNSC staff use a well-established safety and control area (SCA) framework in evaluating each licensee’s safety performance. The framework includes 14 SCAs covering all technical areas of regulatory oversight. For the purpose of this report, safety performance is evaluated by presenting licensees’ regulatory compliance in select SCAs (i.e., management system, operating performance, radiation protection, security and ‒ for the waste nuclear substance sector only ‒environmental protection), as well as effective doses to workers and reported events.

In 2017, as part of the ongoing regulatory oversight of licensees, CNSC staff conducted compliance verification activities consisting of field inspections, desktop reviews and technical assessments of licensee activities. The evaluations of findings for the SCAs covered in this report show that, overall, licensees made adequate provision for the protection of the health, safety, national security,and the environment from the use of nuclear substances, and took the measures required to implement Canada’s international obligations. Based on these evaluations, CNSC staff conclude that the use of nuclear substances and prescribed equipment in Canada remains safe.

Compliance verification

In 2017, CNSC staff conducted 944 inspections across the five sectors, including 160 security inspections to verify compliance with security expectations including incremental requirements outlined in REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources, for Category 1 and 2 sealed sources.

Overall, licensees showed satisfactory compliance ratings in all of the SCAs examined in this report. Where non-compliances were identified, CNSC staff ensured that licensees took appropriate corrective actions. Any non-compliances that had immediate risks to health, safety or security were addressed immediately by licensees. The majority of inspected licensees in 2017 were found to be compliant with the requirements in the SCAs covered in this report:

- In “management system”, 97% of the licensees inspected ensured that adequate processes and programs were in place to achieve their safety objectives.

- In “operating performance”, 85% of the licensees inspected made adequate provisions for the health, safety, security, and protection of the environment.

- In “radiation protection”, 85% of the licensees inspected had measures and programs in place to ensure that exposure to workers and the public to ionizing radiation was monitored, controlled and remained ALARA (as low as reasonably achievable).

- In “security”, 90% of the licensees inspected demonstrated that they have adequate provisions in place to prevent the loss, sabotage, illegal use, illegal possession or illegal removal of nuclear substances and prescribed equipment in their care and control.

- In “environmental protection”, 100% of the waste nuclear substance licensees inspected managed and monitored environmental emissions in a satisfactory manner.

As part of the phased implementation of REGDOC-2.12.3, security inspections were conducted for licensees in possession of high-risk sources in 2017; 73% of the inspections resulted in fully satisfactory or satisfactory ratings for the regulatory requirements imposed by REGDOC-2.12.3. Licensees have put in place measures to correct all non-compliances noted during these inspections. Details of the security inspections, such as non-compliances, are not provided in this report due to their sensitive nature.

Compliance enforcement

The CNSC uses a graded approach to enforcement to compel compliance and deter future non-compliances. When non-compliance (or continued non-compliance) has been identified, CNSC staff assess the significance of the non-compliance and determine the appropriate enforcement action, based on the CNSC’s graded approach to enforcement.

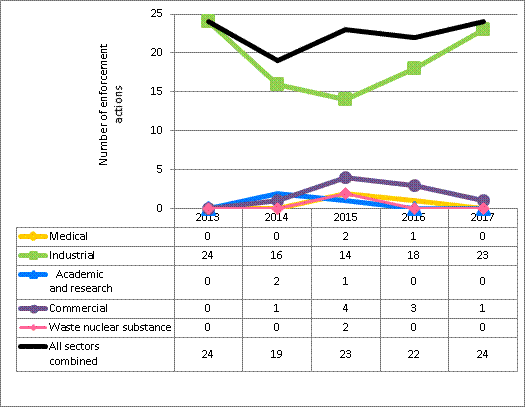

In 2017, the CNSC took 24 escalated compliance enforcement actions against licensees in the five sectors, including 18 orders and six administrative monetary penalties (AMPs). Most of the enforcement actions were taken against licensees in the industrial sector, consistent with trends from previous years. CNSC staff reviewed corrective measures implemented by all of the licensees to which orders were issued and found them to be satisfactory. Five of the six AMPs have been paid.

Effective doses to workers

Licensees are required to keep radiation doses to persons below CNSC regulatory limits and ALARA in accordance with the radiation protection programs established under the CNSC licences.

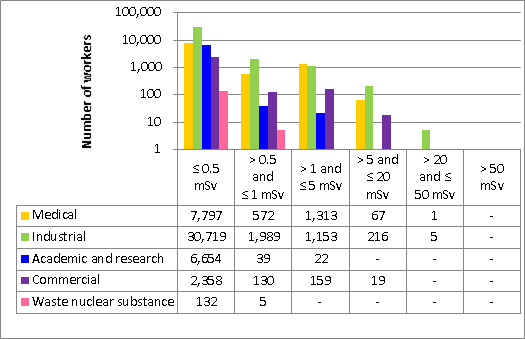

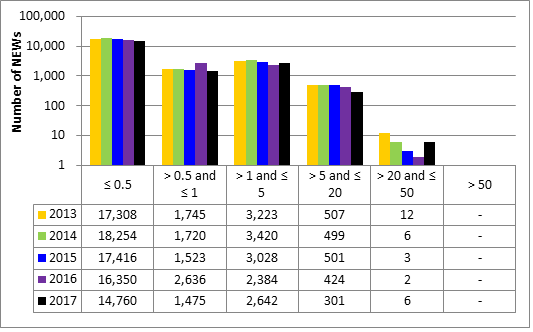

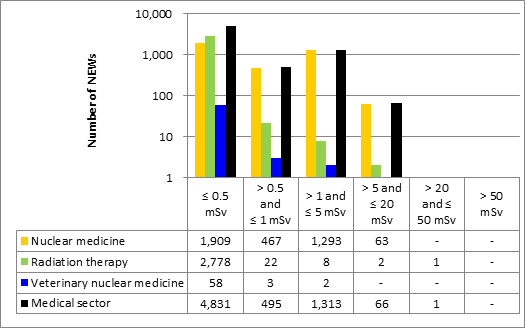

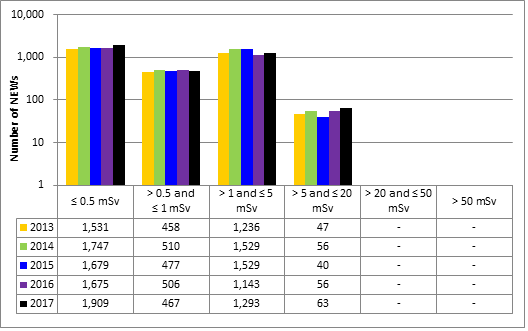

In 2017, doses were monitored for 53,350 workers in the five sectors covered in this report. Of those workers, 19,184 were designated as nuclear energy workers (NEWs). The remaining 34,166 were not designated as NEWs, and are referred to as non-NEWs in the report. Exposures to radiation continued to be very low for workers in 2017, consistent with previous reporting years.

One NEW in the medical sector received an extremity dose of 2,366 mSv (millisieverts) from handling a contaminated cart in a clinic. This dose was above the regulatory limit of 500 mSv. The incident was reported to the Commission in April 2017, and additional details can be found in section 5.7 of the report.

Reported events

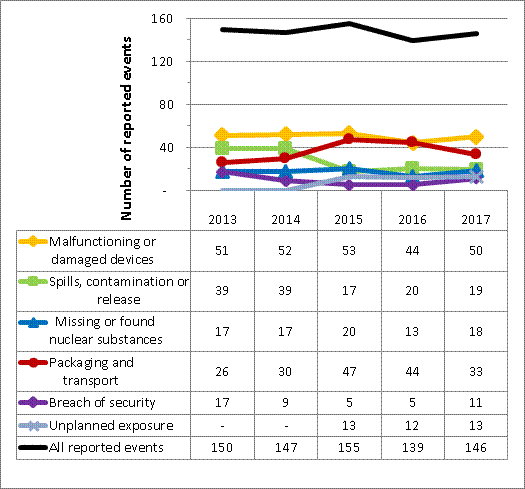

CNSC staff assessed the 146 events reported by licensees covered in this report. Reported events have been ranked using the International Nuclear and Radiological Event Scale. Of these, 144 were ranked as level 0 (no safety significance), 1 was ranked as level 1 (anomaly) and 1 was ranked as level 2 (incident).

For all of the events reported, licensees implemented appropriate response measures to mitigate the impacts of the events and to limit radiation exposure to workers and the public. CNSC staff reviewed the measures and found them to be satisfactory.

Conclusion

Based on the CNSC’s comprehensive regulatory oversight of the industry, CNSC staff conclude that the use of nuclear substances in Canada is safe. Licensees corrected identified non-compliances to the satisfaction of CNSC staff; adequate provisions are in place for the protection of the health, safety and security of persons and the environment from the use of nuclear substances.

1 Background

1.1 Background

The Canadian Nuclear Safety Commission (CNSC) regulates the use of nuclear energy and materials to protect health, safety, security and the environment; to implement Canada’s international commitments on the peaceful use of nuclear energy; and to disseminate objective scientific, technical and regulatory information to the public. Persons licensed by the CNSC are responsible for operating their facilities and managing their activities safely, and are required to implement programs that make adequate provisions for protecting health, safety, security and the environment. The CNSC is responsible for setting the requirements and verifying compliance against those requirements.

Each year, CNSC staff assess the overall safety performance of the use of nuclear substances in Canada. Staff consider industry performance as a whole, as well as the performance of each sector (i.e., medical, industrial, academic and research, commercial, and waste nuclear substance) separately. This assessment is summarized in this document.

For a comprehensive overview of the CNSC and its activities, consult the CNSC’s annual report, Safety First.

Regulatory oversight

The CNSC regulates the nuclear industry in Canada through a comprehensive program of licensing, certification, compliance verification and enforcement. For each of the nuclear sectors described in this report, CNSC staff evaluate safety performance through assessments, inspections, reviews, and evaluations of licensee programs and processes.

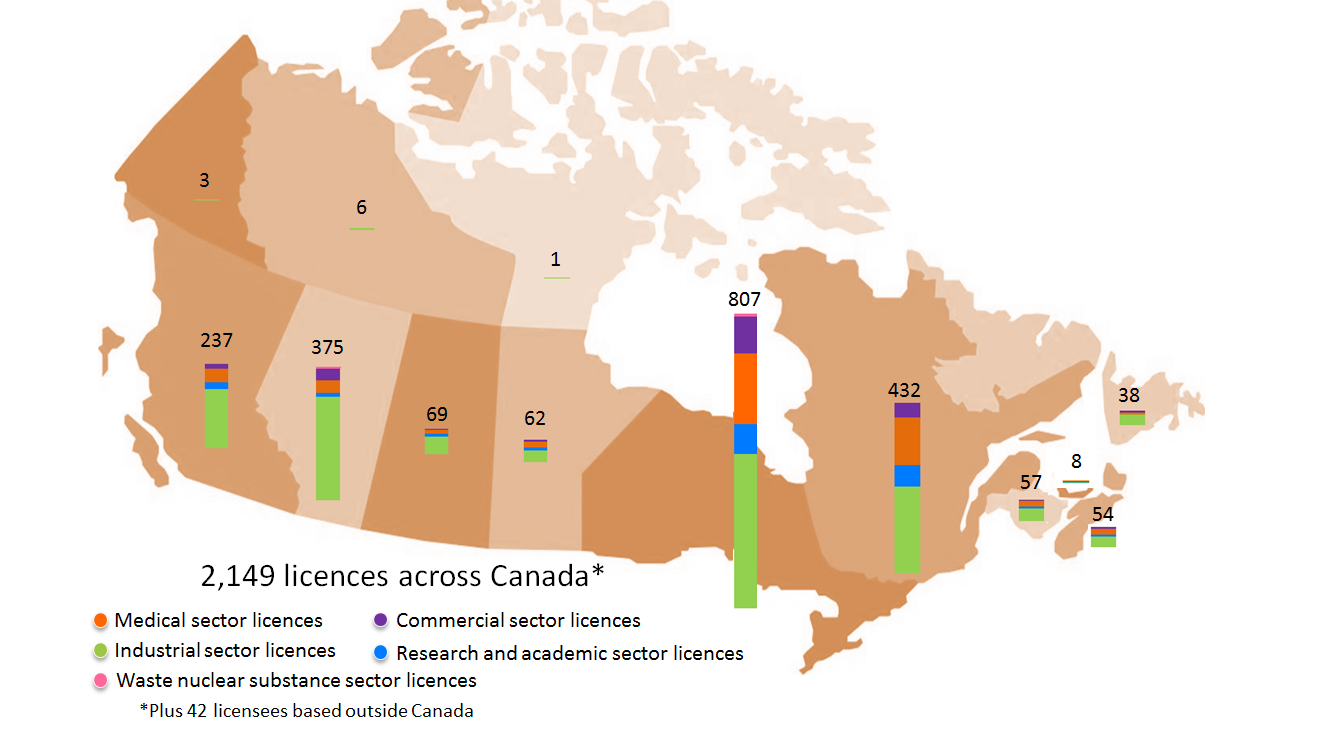

These regulatory programs cover various types of activities across all provinces and territories, as shown in figure 1. Licensees include hospitals; universities and research institutions; and a wide variety of industrial manufacturing and production facilities including those that store, produce or service nuclear substances and devices, and operate and service prescribed equipment; and installations that store and process low-level waste from nuclear facilities and activities.

The safe use of nuclear substances in Canada is demonstrated through licensees’ compliance with the Nuclear Safety and Control Act (NSCA) and its associated regulations, as well as specific conditions set out in CNSC licences. The NSCA, its regulations and the licences require that licensees implement and maintain appropriate programs to ensure the safety and security of nuclear-related activities, minimize doses to workers and the public, protect the environment and minimize consequences of events.

Figure 1: Distribution of licensees in the provinces and territories of Canada

Description

Some licensees that hold CNSC licences to service radiation devices or prescribed equipment are based outside Canada and come to Canada to perform maintenance or servicing work on equipment owned by other licensees. When they work in Canada, these licensees are subject to the same level of regulatory oversight from the CNSC as those whose operations are based in Canada.

2 Report overview

This regulatory oversight report focuses on the results of compliance verification and enforcement activities in 2017 for licensees authorized for activities involving nuclear substances or prescribed equipment. For the purposes of reporting, licensees are grouped in five sectors:

- medical

- industrial

- academic and research

- commercial

- waste nuclear substance

Each sector’s performance is outlined in an individual section in this report.

The waste nuclear substance licensees included in this report handle low-level waste from research laboratories, as well as slightly contaminated metals, laundry and equipment from other types of nuclear facilities.

There are three parts to this report:

- regulatory process and developments

- overall safety performance assessment

- sector-specific safety performance assessments

2.1 Safety and control area framework

To ensure comprehensive regulatory oversight and reporting of licensed activities, CNSC staff have developed a set of safety and control areas (SCAs). SCAs have been in use for a number of years, and represent a well-established set of technical areas that have proven effective in evaluating licensee safety performance of regulated facilities and activities under the CNSC’s purview. The CNSC has defined 14 SCAs:

- management system

- human performance management

- operating performance

- safety analysis

- physical design

- fitness for service

- radiation protection

- conventional health and safety

- environmental protection

- emergency management and fire protection

- waste management

- security

- safeguards and non-proliferation

- packaging and transport

2.2 Safety performance measures

During licensing and compliance activities, CNSC staff review the licensee’s (or applicant’s) performance within each relevant SCA by reviewing licensee documents and conducting inspections. The broad nature of the different activities conducted by licensees covered by this report means that not all SCAs apply to all activities or all licensees.

For the purpose of this report, the performance in a subset of the SCAs is reviewed. The following four SCAs are the most relevant indicators of safety performance for licensees in the sectors covered in this report: management system, operating performance, radiation protection and security. In addition, ratings for the environmental protection SCA are included for the waste nuclear substance sector. Environmental protection SCA ratings are not reported for the other sectors because the majority of nuclear substance and radiation device licensees are authorized to possess and use sealed sources and radiation devices, which have no impact on the environment (as per REGDOC-2.9.1, Environmental Protection: Environmental Principles, Assessments and Protection Measures, version 1.1). Sealed sources are designed to international standards and must meet stringent design requirements. The CNSC certifies all radiation devices to ensure that they are safe for use and meet CNSC requirements, which includes an assessment of their design. In addition, the CNSC regulations require regular leak testing of sealed sources, thereby ensuring that the environment is protected.

The unsealed nuclear substances, used by a small group of CNSC licensees, are short-lived radionuclides. Their use is confined to controlled rooms or laboratories designed in accordance with regulatory requirements, including associated work practices, that prevent the release or uncontrolled release of nuclear substances to the environment. These measures form a part of the licensing basis for the CNSC licence issued. CNSC staff verify compliance with these measures through compliance activities.

For waste nuclear substance licensees that may have interactions with the environment, releases to the environment are monitored and reported to the CNSC. Environmental releases are minimized through the use of emissions control technologies such as HEPA (high-efficiency particulate air) filters and waste water collection tanks, which is consistent with the principles outlined in REGDOC‑2.9.1. Emissions from waste nuclear substance licensees have historically been below levels that would pose a risk to the public or the environment. CNSC staff are satisfied that there are adequate measures in place to protect the public and the environment.

Performance in the packaging and transport SCA is not explicitly covered in the report. However, events related to packaging and transport are included in the report, and provide an indication of their impacts to health and safety of persons and to the environment. CNSC staff review all events reported and ensure licensees implement adequate corrective measures. Compliance ratings – also referred to as inspection ratings – reflect overall licensee performance for the SCAs covered in this report. The nature, type and safety significance of events reported by licensees, as well as the type of enforcement actions taken by the CNSC in 2017, are provided as supplementary indicators of safety performance. Data from 2013 to 2017 are included in figures for each of these safety indicators in order to identify five-year trends. Each performance measure is described below.

Although not incorporated into this report, all relevant SCAs are assessed during compliance inspections and reviews of licensees’ documents, and a compliance rating similar to those found in this report is assigned for each SCA. All required corrective actions arising from below-satisfactory performance are tracked and followed up by CNSC staff to ensure that all non-compliances are addressed to the satisfaction of the CNSC.

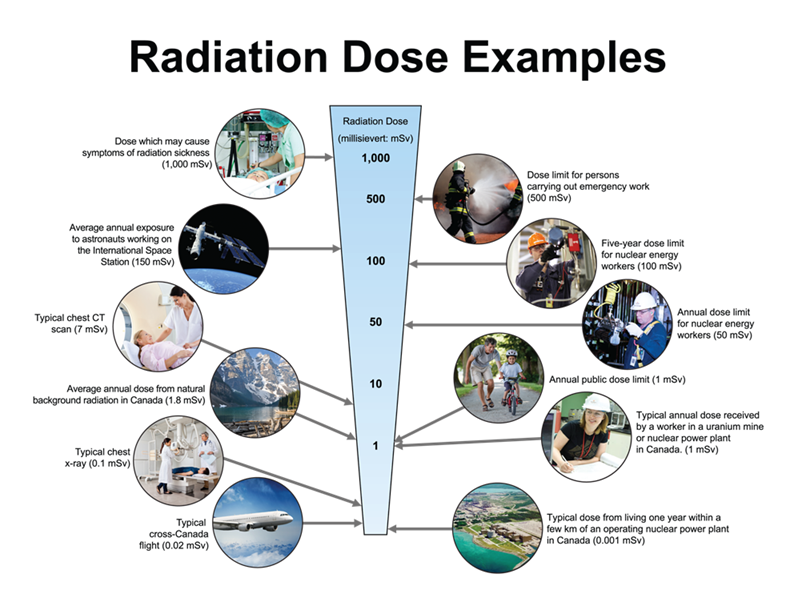

2.2.1 Doses to workers

Each licensee is required to implement a radiation protection program that ensures that the radiation doses to workers are well below regulatory limits and kept ALARA (as low as reasonably achievable), with social and economic factors taken into account. Thus, ascertainment of the magnitude of doses received by workers is an integral part of a licensee’s radiation protection program.

This report references two groups of workers that perform the types of activities referenced in a CNSC licence: those designated as nuclear energy workers (NEWs) and those not designated as NEWs (non-NEWs). The term “NEW” means a person who is required, in the course of his or her business or occupation in connection with a nuclear substance or nuclear facility, to perform duties in circumstances that may result in receiving a dose of radiation greater than 1 millisievert (mSv) per year. A worker not designated as a NEW means a person is unlikely to receive a dose greater than 1 mSv per year while performing duties in connection with a nuclear substance or nuclear facility. This report provides dose information for all workers, while primarily focusing on those designated as NEWs.

The CNSC’s regulatory effective dose limits for NEWs are set at 50 mSv in any one-year dosimetry period and a total of 100 mSv over a five-year dosimetry period. The one-year dosimetry period covers January 1 to December 31 of every year. The current five-year dosimetry period started on January 1, 2016 and will end on December 31, 2020. For all persons not designated as NEWs, and for all members of the general public, the effective dose limit is 1 mSv per calendar year.

Additionally, the CNSC’s Radiation Protection Regulations set out equivalent dose limits for the lens of the eye, the skin, and the hands and feet, for NEWs and all other persons.

Appendix A provides more information on occupational exposure, ascertaining worker doses and measures to be taken by licensees when a dose limit is exceeded.

2.2.2 Management system

The management system SCA covers the framework that establishes the processes, programs and resources required to ensure that a licensee achieves its safety objectives, continuously monitors its performance against those objectives, and fosters a healthy safety culture.

2.2.3 Operating performance

Operating performance refers to the licensee’s ability to perform licensed activities in accordance with pertinent operational and safety requirements defined in the NSCA, its associated regulations and licence conditions. Licensees are expected to demonstrate that they comply with operational and safety requirements by providing workers with appropriate procedures for the safe use of nuclear substances and prescribed equipment, by ensuring that workers follow procedures and by maintaining records that demonstrate compliance.

2.2.4 Radiation protection

Radiation protection programs are required for every licensee to ensure that contamination levels and radiation doses received by workers are monitored, controlled and maintained below regulatory dose limits, and kept ALARA, with social and economic factors taken into account. Licensees can meet these objectives by monitoring worker doses; posting radiation warning signs; planning appropriately for radiological emergencies; managing oversight of operational activities; and instituting effective workplace practices that emphasize the use of time, distance and shielding to minimize exposure to radiation, and emphasize the use of appropriate protective equipment.

2.2.5 Environmental protection

The environmental protection SCA covers the measures licensees have in place to manage and monitor any environmental emissions. The scale and complexity of the environmental protection program is commensurate with the environmental risk associated with the licensed activity.

2.2.6 Security

The security SCA covers the physical security measures, practices and programs that licensees are required to have in place to prevent the loss, illegal use, illegal possession or illegal removal of nuclear substances during their entire lifecycle, including while they are in storage or during transport. The extent of the security measures required depends upon the types of nuclear substances used and activities performed by each licensee.

The safety and security of sealed sources is increased through effective control and tracking. CNSC compliance inspections include requirements to verify sealed source tracking information.

To ensure proper regulatory oversight of the requirements related to the first phase of the implementation of REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources, CNSC staff conduct security inspections for those in possession of Category 1 and 2Footnote 1 sealed sources. Non-compliance details for these inspections are not included in this report due to their sensitive nature.

2.2.7 Enforcement actions

The CNSC may take a variety of enforcement actions to ensure that licensees correct non-compliances in an effective and timely manner. The type of enforcement action taken is commensurate with the risk the non-compliance presents to the environment, the health and safety of workers and the public, and to national security. This report provides detailed information on the following types of enforcement actions taken by the CNSC: orders, administrative monetary penalties (AMPs), decertification of certified exposure device operators and decertification of radiation safety officers at Class II nuclear facilities. Appendix B provides a list of all orders and AMPs issued to nuclear substance and radiation device licensees by the CNSC in 2017.

No exposure device operators or Class II radiation safety officers were decertified in 2017.

2.2.8 Reported events

Under the NSCA and its associated regulations, licensees are required to immediately report to the CNSC events related to their licensed activities that are of regulatory interest. Within 21 days of becoming aware of the incident, licensees are required to submit a written report to the CNSC on the event. The written report must include an analysis of the cause and circumstances of the event, as well as any measures taken, or proposed to be taken, by the licensee to prevent recurrence. Together, the initial and final reports allow the CNSC to verify whether the licensee has taken appropriate measures to mitigate the event and implemented adequate corrective actions to prevent recurrence.

The CNSC uses the International Nuclear and Radiological Event Scale (INES) tool to categorize events in the sectors covered by this report. Additional information on the INES classification can be found on the CNSC website.

2.3 Data collection

Compliance ratings, non-compliance data, and CNSC enforcement actions were obtained from the CNSC’s compliance verification and enforcement program in 2017.

Annual compliance reports submitted by licensees in calendar year 2017 provided the data on doses incurred by all persons engaged in licensed activities in the five sectors covered in this report.

2.4 Glossary

For definitions of terms used in this document, see REGDOC‑3.6, Glossary of CNSC Terminology, which includes terms and definitions used in the Nuclear Safety and Control Act and the regulations made under it, and in CNSC regulatory documents and other publications.

2.5 Changes to the 2017 regulatory oversight report

CNSC staff introduced the following additions to this year’s report:

-

Waste nuclear substance licensees have been included as a fifth sector.

- These are licensees authorized by the designated officer to manage, handle, store and process low-level radioactive waste.

- Previously, these licensees were reported as part of the Regulatory Oversight Report for Waste Management, Storage and Processing in Canada: 2015.

- The relative risk of subsectors highlighted in the report has been included.

3 Regulatory program for the use of nuclear substances

The possession, use, transfer, import, export, abandonment and storage of nuclear substances must be licensed by the Canadian Nuclear Safety Commission (CNSC) when the amount of nuclear substance involved is greater than its exemption quantity (see Schedule 1 of the Nuclear Substances and Radiation Devices Regulations). Facilities where certain types of Class II prescribed equipment is to be installed must also be licensed by the CNSC prior to their construction, operation or decommissioning. A licence is also required to service radiation devices or Class II prescribed equipment.

All licensees that operate Class II nuclear facilities or that service Class II prescribed equipment must have a certified radiation safety officer (RSO) and a qualified temporary replacement. The RSO is responsible for implementing the radiation protection program, and ensuring that licensed activities are conducted safely and all regulatory requirements are met.

All radiation devices and most Class II prescribed equipment, as well as certain types of transport packages, must be certified by the CNSC before they can be used in Canada.

The CNSC’s compliance and verification program measures licensee compliance with CNSC regulatory requirements. Regular inspections and desktop evaluations verify that licensees comply with the Nuclear Safety and Control Act (NSCA) and its associated regulations, as well as any conditions included in their licences.

To determine appropriate levels of regulatory monitoring and control, CNSC staff establish compliance verification plans for each nuclear sector that are based on risk-informed regulatory oversight of each sector’s activities. Modifications to the compliance plans are made on an ongoing basis in response to events and changes in licensees’ performance.

For the activities covered in this report, the CNSC’s risk-informed regulatory program is applied in the following way:

- Each licensed activity is assigned a weighting factor – a coefficient that represents the activity’s relative significance with respect to risk.

- Factors considered in weighting include the form of the nuclear substances (e.g., sealed source, unsealed source or radiation device), the location where the material is being used (e.g., a work site or a controlled facility), and the compliance history of licensees conducting licensed activities.

- Generally, licensees are inspected on a one- to five-year cycle, based on their risk ranking.

The risk-informed regulatory program provides:

- a risk ranking that recognizes the potential safety impact of the licensed activity

- effective and informed allocation of regulatory oversight effort according to the risk ranking by licensed activity and by licensee performance history

- effective, transparent, consistent and comprehensive regulatory oversight

3.1 CNSC regulatory effort

The CNSC’s risk-informed regulatory program applies resources and regulatory oversight commensurate with the risk associated with the regulated activity. Regulatory effort related to licensing, certification and compliance verification is derived from this program. A total of 944 inspections were completed in 2017, compared to 1,452 inspections in 2016. The decrease in the number of inspections is related to several factors, including:

- transition to radiation protection program reviews through an increase in Type I inspections, which provide a broader assessment of licensee program performance, although with substantially higher effort per inspection ‒ this is consistent with the radiation protection program oversight strategy presented to the Commission in 2016

- increased focus on full inspection coverage of licensee locations in order to verify licensee compliance at remote locations, with increased travel time associated with each inspection

- completion of security inspection campaign for the first phase of implementation of REGDOC-2.12.3 for high-risk sealed sources

- increased mobility of inspectors in 2017, leading to the development of a staffing strategy to hire and train new inspectors in order to manage long-term impacts on the compliance program

The CNSC takes a risk-informed approach to compliance verification, whereby the planning and execution of compliance activities are commensurate with the risk of the licensed activity. High-risk licensees continue to be prioritized for inspections, and all high-risk inspections were completed per the inspection plan.

Inclusion of an additional sector, the waste nuclear substance licensees, had a minimal impact on the total number of inspections, as only four inspections were conducted in this sector in 2017.

Type I inspections of Class II licensees are conducted as per the risk-informed regulatory program.

As shown in table 1, CNSC staff direct effort for regulating the use of nuclear substances and prescribed equipment in 2017 amounted to close to 13,059 person-days, or the annual equivalent of approximately 58 full-time staff.

| Activity | Person-days |

|---|---|

| Licensing | 4,602 |

| Certification | 1,629 |

| Compliance verification | 7,280 |

3.2 Licensing

To obtain a licence, an applicant must submit an application to the CNSC. The CNSC will issue a licence only when the applicant:

- is deemed qualified to carry on the activity that the licence will authorize

- has demonstrated that they will protect the health and safety of persons and the environment

- has demonstrated that they will maintain national security

- has confirmed that they will adhere to international obligations to which Canada has agreed

CNSC staff perform a risk-informed technical assessment of applications submitted to the CNSC.

The CNSC has produced a series of licence application guides to ensure that its expectations for applicants are clear, and to facilitate applicants’ interactions with the regulator. These guides are reviewed on a five-year cycle as part of the regulatory framework review to ensure that they continue to reflect modern regulatory expectations and provide useful guidance to the regulated community. This practice, in turn, facilitates CNSC licensing reviews and minimizes regulatory burden. Application forms and guides for nuclear substances and radiation devices as well as for Class II facilities and prescribed equipment can be found on the CNSC website.

When applying for licence renewals, existing licensees are subject to the same scrutiny as new applicants. The CNSC decision to renew a licence is based on the application information submitted, such as ensuring that there are no outstanding cost recovery fees and the financial guarantee is up to date, and there is a satisfactory compliance history. This includes a review of compliance information such as inspection results, reported incidents and events, and annual compliance reports. A peer review by another CNSC staff member is conducted following the initial review of all licence applications.

If the application satisfies the above requirements, the Commission, or a designated officer authorized by the Commission, may issue a licence authorizing the licensee to conduct the activities requested in the application. The licence includes provisions that define and limit the scope of the authorized activities, as well as specific conditions that must be fulfilled by the licensee when conducting those activities.

The number of licences by sector is shown in table 2. The number of licences issued for activities covered by this report continues to decrease. There are fewer licensees in each of the medical, industrial, and academic and research sectors. The CNSC’s policy to consolidate licences where appropriate is one driver of this reduction, particularly in the medical and academic and research sectors. In the industrial sector, however, the decrease in the number of licences is driven to a greater extent by the economic conditions and business decisions of the licensees, including larger companies acquiring smaller ones and some licensees moving to non-nuclear technologies.

| Sector | 2013 | 2014 | 2015 | 2016 | 2017 |

|---|---|---|---|---|---|

| Medical | 552 | 536 | 494 | 470 | 457 |

| Industrial | 1,440 | 1,398 | 1,349 | 1,308 | 1,287 |

| Academic and research | 232 | 229 | 207 | 208 | 195 |

| Commercial | 256 | 248 | 245 | 247 | 246 |

| Waste nuclear substance | 8 | 8 | 6 | 7 | 6 |

| Total | 2,488 | 2,419 | 2,301 | 2,231 | 2,191 |

3.3 Certification of prescribed equipment

An application for certification must be submitted to the CNSC before the prescribed equipment can be used in Canada. CNSC staff who conduct the technical evaluations of applications for certification are accredited as professional engineers. Upon receipt of an application, CNSC staff conduct a thorough technical review of the information contained in the submission to determine if:

- the radiation device, Class II prescribed equipment or transport package meets all CNSC regulatory requirements and is safe to use

- adequate measures are in place in respect of its use to protect the environment, national security, and the health and safety of persons

A CNSC quality assurance program in the form of a peer review by another CNSC staff member is in place for the review of applications for certification of prescribed equipment.

If satisfied that the design meets the above requirements, the Commission, or a designated officer authorized by the Commission, may issue a certificate for the prescribed equipment based on the recommendation of the CNSC staff members who conducted the technical evaluations.

If the design does not comply with the above requirements or if a certified model is found to be unsafe, the designated officer will contact the applicant and all affected parties, such as users in the case of a certified model, to inform them of the decision to either not certify the new model or to decertify a currently certified model. In these cases, the CNSC will provide the applicant and affected parties an opportunity to be heard in accordance with the process specified in the regulations.

Regulatory documents REGDOC-1.5.1, Application Guide: Certification of Radiation Devices or Class II Prescribed Equipment and RD/GD-352, Design, Testing and Performance of Exposure Devices outline CNSC expectations for the certification of radiation devices and Class II prescribed equipment, while RD/GD- 364, Joint Canada – United States Guide for Approval of Type B(U) and Fissile Material Transportation Packages (currently under review), outlines CNSC expectations for the certification of transport packages.

3.4 Certification of exposure device operators

Licensees are required under the Nuclear Substances and Radiation Devices Regulations to permit only CNSC-certified personnel and supervised trainees to use exposure devices containing nuclear substances. In 2017, the CNSC certified 87 new exposure device operators (EDOs) and renewed the certifications of 302 others. EDOs must renew their certification every five years to ensure they maintain the knowledge and skills required to operate an exposure device safely.

The CNSC EDO certification program is designed to ensure the continued competency of the operator, and maintain the safety and security of persons and devices when working with exposure devices. Certified individuals must demonstrate the ability to:

- handle, transport, store and operate exposure devices and any accessories to the devices safely and securely

- properly utilize radiation detection and monitoring equipment

- understand the obligation to comply with all relevant regulatory requirements

Figure 2: CNSC inspector observes a certified exposure device operator preparing for industrial radiography on a pipeline (Source: CNSC)

Regulatory document REGDOC-2.2.3, Personnel Certification: Exposure Device Operators, and CSA Group document CSA PCP-09, Certified Exposure Device Operator Personnel Certification Guide (under review), outline the CNSC’s requirements and guidance for certification as an EDO and for renewal of an EDO certification. In 2017, CNSC staff updated the EDO certification application forms and the CNSC Web page on EDO certification. The EDO application forms were redesigned in order to standardize the information submitted in EDO applications to ensure that the CNSC receives all of the information necessary to process the applications. The new forms have reduced the need for CNSC staff to request applicants to provide additional information to support their EDO applications, and have reduced the time needed to process EDO certification applications.

The CNSC may take regulatory action if an EDO is found to be operating contrary to safety protocols and conditions, or if an EDO is causing undue risk to the public or the environment. No EDOs were decertified in 2017.

3.5 Certification of Class II radiation safety officers

All licensees that operate Class II nuclear facilities or that service Class II prescribed equipment must have a certified radiation safety officer (RSO) and a qualified temporary replacement. The RSO ensures that licensed activities are conducted safely and all regulatory expectations are met.

There are two components to the RSO certification process:

- an assessment of the candidate’s capability to perform the duties of the position, based on the submitted application

- an assessment of the candidate’s knowledge of the licensed activities, based on an examination

RSO candidates must possess certain qualifications before they can be considered for certification. For most Class II licensed activities, candidates must have at least a bachelor’s degree in engineering or science from a recognized university.Footnote 2 Alternative education qualifications may be reviewed on a case-by-case basis.

If the candidate is able to clearly demonstrate their knowledge as it relates to the RSO position within their organization, the Commission or a designated officer authorized by the Commission may certify the candidate in the position of RSO.

The process for certification of Class II RSOs, along with guidance for applicants, is outlined in REGDOC-2.2.3, Personnel Certification: Radiation Safety Officers.

In 2017, the CNSC certified 28 applicants as Class II RSOs. No Class II RSOs were decertified in 2017. The CNSC has certified 240 Class II RSOs since 2010.

3.6 RSO appointment for nuclear substances and radiation devices licences

There are approximately 1,660 RSOs appointed for nuclear substances and radiation devices licences. The designation of an RSO for nuclear substances and radiation devices licences is the responsibility of the applicant authority, the person accountable for the management and control of the licensed activity. The RSO is the person the CNSC will contact about radiation safety and compliance matters. The appointment of these RSOs does not involve a certification process.

The CNSC requires that the RSO’s qualifications be included in a licence application, and will determine if the RSO has sufficient knowledge and expertise with regard to the applicant’s proposed activities. The RSO may be a consultant hired by the applicant to carry out this role, provided that the consultant is clearly designated by the applicant authority to do so. Such information must be communicated to the CNSC as part of the licence application process. Site RSOs may be utilized where a licensee has multiple locations of licensed activity.

Unless otherwise noted by the applicant authority, the RSO will be considered to have the authority to act for the applicant and will have signing authority for all matters encompassed by the CNSC licence.

For new applicants of licences for high-risk activities (for example, industrial radiography, well logging), CNSC staff perform additional verifications as part of the licensing process. They meet with the designated RSO and the applicant authority during a pre-licensing visit to verify the RSO’s knowledge of the licensee’s proposed radiation protection program and confirm that the applicant understands their obligations as a licensee. CNSC staff plan visits and prepare the interview following review of the application and the applicant’s radiation protection program. During the visit, CNSC staff ensure that the licensee understands the radiation protection program that has been committed to and review the location of the proposed licensed activities. At the same time, CNSC staff ensure that candidates have strong radiation safety knowledge as well as advanced training in operational and emergency procedures. If it is deemed that the appointed RSO does not have adequate knowledge, the licensing decision will be withheld pending the appointment of a suitable RSO. In 2017, CNSC staff performed nine pre-licensing visits for prospective nuclear substance and radiation device licensees. In two cases, CNSC staff found deficiencies in either the RSO’s knowledge of the radiation protection program or the radiation program itself. In these cases, the licence was not issued until the concerns were addressed to the satisfaction of CNSC staff.

3.7 RSO appointment for waste nuclear substance licences

Each waste nuclear substance licensee designates an individual who is responsible for implementing the licensee’s radiation protection program: the radiation protection program authority. The responsibilities of the position are the same, regardless of whether the job title is “radiation safety officer” or something else.

3.8 Licensing and certification decisions

CNSC designated officers made a total of 2,571 licensing and certification decisions related to activities covered in this report in 2017. The majority of these were licensing decisions, as shown in table 3.

There was an increase in the number of certification activities in 2017 due to the expiry and recertification of a higher-than-average number of device certificates, a trend that began in 2016. In 2018, the number of device certifications is expected to drop back to levels seen prior to 2015.

After peaking at 455 in 2016, the number of decisions related to the certification of exposure device operators (EDOs) returned to what is expected to be normal levels of approximately 400 per year. The increased number of EDO certification renewals in 2016 was attributed to the CNSC’s gradual implementation of a new expectation that came into effect in 2015 for EDOs to renew their certification every five years as per CSA Group document CSA PCP-09, Certified Exposure Device Operator Personnel Certification Guide. In 2018, the number of EDO certifications is expected to be similar to the 2017 levels, as the EDO certification and certification renewal programs as per CSA PCP-09 have matured and started to stabilize.

| Type of decision | Number of decisions |

|---|---|

| Licensing (issuance of new licences, licence renewals, licence amendments, licence revocations and licence transfers) | 1,972 |

| Certification of prescribed equipment (radiation devices, Class II prescribed equipment and transport packages) | 182 |

| Certification of EDOs (issuance of new certification and renewal of certification) | 389 |

| Certification of Class II RSOs | 28 |

| Total | 2,571 |

3.9 Compliance verification and enforcement

The CNSC verifies compliance by conducting site inspections and reviewing licensee documentation and operational activities. Licensees are required to report routine performance data through annual compliance reports and the occurrence of specific types of events. In addition, the CNSC conducts investigations of unplanned events, public complaints or accidents involving nuclear substances.

The CNSC uses a graded approach to enforcement to encourage compliance and deter future non-compliances. When a non-compliance (or a continued non-compliance) has been identified, CNSC staff assess its risk and safety significance to determine appropriate enforcement action. The chosen enforcement action is commensurate with the risk that the non-compliance presents to the environment, the health and safety of workers and members of the public, and to national security. Enforcement actions vary with non-compliance severity, and can include orders and administrative monetary penalties (AMPs). Each is a discrete and independent response to a non-compliance.

Escalated enforcement actions were taken 24 times in 2017 against licensees in the sectors covered in this report. The majority were in response to inspection findings.

In 2017, CNSC staff conducted 944 inspections to verify compliance with CNSC regulatory requirements, including 160 security inspections to verify compliance against the requirements of REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources, for Category 1 and 2 sealed sources.

3.10 Stakeholder engagement

Clarity of requirements is one of the CNSC’s corporate priorities. Stakeholder engagement and outreach are two tools the CNSC uses to meet this priority. Outreach and engagement lead to an increased awareness and better understanding of the regulatory process and requirements, which, in turn, lead to increased workplace safety. CNSC staff take every opportunity to perform outreach, including while on inspection. Furthermore, to improve the public’s level of understanding of proposed or licensed nuclear facilities and activities, some Class II licensees are required to develop and implement a public information program that includes a disclosure protocol.

CNSC outreach sessions held throughout Canada in 2017 gave licensees and others the opportunity to interact with the regulator outside the scope of an inspection or licensing activities. This past year, digital technologies such as WebEx were used to host virtual outreach sessions and working group meetings. Some of the key sessions are described below. In addition to outreach sessions, CNSC staff delivered presentations at various conferences to share information on developing regulatory topics.

Figure 3: CNSC information booth at the Family Medicine Forum in Montréal, QC

3.10.1 Outreach to licensees

Outreach sessions

Since 2009, the CNSC has offered an outreach program for licensees that use nuclear substances and prescribed equipment. The presentations made by CNSC staff and discussions associated with outreach are meant to inform licensees and other persons regulated by the CNSC about recent and upcoming regulatory changes, and provide education regarding the CNSC’s expectations for licensing and compliance requirements. In 2017, outreach sessions were held in Winnipeg, Manitoba and Vancouver, British Columbia.

Newsletters

In 2009, the CNSC introduced the DNSR newsletter as an outreach vehicle for disseminating regulatory and safety information to licensees that use nuclear substances and prescribed equipment in Canada. The newsletter articles address various regulatory compliance issues and support the regulator’s commitment to keep both licensees and the public informed. Regular editions of the newsletter provide valuable information to licensees in all sectors; special editions focus on either a specific subsector or an area of regulatory interest.

All newsletters are posted on the CNSC website and are sent to recipients on the CNSC subscription list.

In 2017, two editions of the DNSR newsletter were published: a spring edition in June and a fall edition in December. Topics included information for licensees on how and when to report an event to the CNSC; operating experience and lessons learned from the nuclear medicine and portable gauge industries; information about implementation of REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources, for users of Category 3, 4 and 5 sealed sources; a summary of regulatory actions; a summary of events reported to the International Atomic Energy Agency (IAEA) by other countries; and a summary of events reported to the CNSC.

Safety posters

In 2017, CNSC staff published updated safety posters on laboratory classifications, spill procedures, responding to accidents involving portable gauges, and the proper use and care of personal dosimeters.

3.10.2 Outreach to the medical sector

Canadian Radiation Protection Association working group

A working group was established between the CNSC and the Canadian Radiation Protection Association (CRPA) in 2014. In 2017, this working group continued its efforts to promote strong radiation safety cultures within licensed activities. Topics of discussion at meetings this past year included proposals for licence consolidation of nuclear substance and radiation device licences, the evaluation the CNSC is conducting on success factors for a radiation protection program, and upcoming changes to regulatory documents.

Canadian Radiation Protection Association meeting

For almost three decades, CNSC staff have delivered regulatory-focused presentations and participated in regulatory workshops at the CRPA’s annual conferences. At the 2017 annual meeting, CNSC staff delivered presentations on identifying success factors of the RSO, the benefits of internal inspections to the radiation protection program, upcoming licensing process reforms and care of decedents. Furthermore, CNSC staff participated in a town hall session to answer questions from conference attendees.

Canadian Organization of Medical Physicists

The Canadian Organization of Medical Physicists (COMP) represents medical physicists working in radiotherapy facilities in the medical sector. Many certified radiation safety officers at Class II nuclear facilities are members of COMP.

CNSC staff attended the 2017 COMP Annual Scientific Meeting in Ottawa, Ontario. CNSC staff participated in a panel discussion on the importance of the RSO and factors influencing success in that role.

CNSC-Class II/CRPA/COMP working group

The CNSC-Class II/CRPA/COMP (C3) working group was established in late 2015 with the mission of providing a forum for communication and information sharing among stakeholders in the regulated Class II community. The group met twice in 2017. Topics discussed included methods for communicating with applicant authorities, the workload of RSOs, the importance of internal audits, and ways to communicate with members of the CRPA and COMP.

Other outreach activities

CNSC staff met with the Cancer Care Ontario RSO Community of Practice to discuss the proposed changes to the licence application guide for Class II licences.

CNSC staff delivered a presentation to the nuclear medicine community at The Ottawa Hospital about the CNSC’s mandate and activities, and specifically about the Directorate of Nuclear Substances Regulation. CNSC staff described how the CNSC conducts inspections of nuclear medicine licensees and provided case studies of challenges associated with nuclear medicine.

On three occasions, CNSC staff hosted webinars for medical licensees that focused on the full implementation of REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources.

The CNSC hosted an information booth at the Family Medicine Forum held in Montréal, Quebec. CNSC staff provided interested attendees with both information on the CNSC’s role in regulating activities in the medical sector, and resources on ionizing radiation and radiation doses.

CNSC staff held a webinar that, while not specific to the medical field, informed funeral industry professionals regarding the proper care of decedents who received radiation therapies or nuclear medicine treatments prior to their death.

3.10.3 Outreach to the industrial sector

Industrial radiography working group

In 2009, a CNSC/industrial radiography working group was established to foster improved communications between the CNSC and the industry. The working group meets twice a year to discuss best practices and safety performance, and provides a forum in which stakeholders can stay informed of new developments from both technical and regulatory perspectives. At the 2017 meetings, the group discussed items of interest to the industrial radiography community, including ways to communicate with and educate industrial radiography clients.

Industrial radiography annual meeting

The CNSC holds two separate annual meetings with the radiography industry. In 2017, the meetings were held in Nisku, Alberta, and Ottawa, Ontario. CNSC staff use these meetings to address recent and upcoming regulatory developments and discuss other areas of regulatory focus. During the 2017 meetings, the CNSC gave presentations on its expectations for radiation protection programs, the process for the certification of exposure device operators (EDOs) and an overview of compliance for the previous year. Representatives of industry delivered presentations to their peers on the experience of conducting internal audits and on the EDO practical examination.

Certified Exposure Device Operator Scheme Committee

In 2016, the CSA Group formed a scheme committee consisting of CNSC staff, Natural Resources Canada staff and representatives from the industrial radiography community to discuss potential updates to CSA Group document CSA PCP-09, Certified Exposure Device Operator Personnel Certification Guide. This committee met in 2016 to discuss committee members’ experience with CSA PCP-09 and to provide suggestions for improvements to the document. CNSC staff are currently using the suggestions from this meeting as a basis to update CSA PCP-09. CNSC staff plan to issue an update to CSA PCP-09 to the CSA Scheme Committee for review in 2018.

In 2017, the CSA Group hosted a working group meeting composed of Scheme Committee members and subject matter experts to review and update the bank of questions and answers for the EDO written examination.

3.11 International commitments

CNSC staff continue to collaborate with international counterparts to support IAEA activities by participating in working groups and technical meetings, contributing to the technical guidance documents and advisory missions, and delivering training programs in other member states. CNSC staff participated in developing a peer review strategy for Africa, providing training in Lithuania, and supporting the development of a number of IAEA safety standards and guides.

In fall 2017, in partnership with the IAEA, the CNSC hosted a three-week training course for Caribbean countries on establishing and strengthening sustainable regulatory infrastructures for the control of radiation sources. Representatives from nine Caribbean countries participated in classroom and field training delivered by CNSC staff. Participants received training on topics that ranged from the Code of Conduct on the Safety and Security of Radioactive Sources to the fine details of inspection and investigation of nuclear medicine sources and equipment, nuclear gauges, industrial radiography and safe transport.

The Joint Convention on the Safety of Spent Fuel Management and on the Safety of Radioactive Waste Management (Joint Convention) was the first legal instrument to directly address these issues on a global scale and was opened for signature on September 29, 1997. Canada was one of the first countries (known as Contracting Parties) to ratify the Joint Convention, which came into force on June 18, 2001.

The Joint Convention applies to spent fuel and radioactive waste resulting from civilian nuclear reactors and applications. The Joint Convention also applies to planned and controlled releases into the environment of liquid or gaseous radioactive materials from regulated nuclear facilities.

The obligations of the Contracting Parties with respect to the safety of spent fuel and radioactive waste management are based to a large extent on the principles contained in the IAEA Safety Fundamentals document, The Principles of Radioactive Waste Management, published in 1995. They include, in particular, the obligation to establish and maintain a legislative and regulatory framework to govern the safety of spent fuel and radioactive waste management, and the obligation to ensure that individuals, society and the environment are adequately protected against radiological and other hazards, by appropriate siting, design and construction of facilities, and by making provisions for ensuring the safety of facilities both during their operation and after their closure. The Joint Convention imposes obligations on Contracting Parties in relation to the transboundary movement of spent fuel and radioactive waste based on the concepts contained in the IAEA Code of Practice on the International Transboundary Movement of Radioactive Waste. Also, Contracting Parties have the obligation to take appropriate steps to ensure that disused sealed sources are managed safely.

The CNSC coordinates and submits the national reports on behalf of Canada. These reports represent a collective work and involve the cooperation of various federal departments, as well as input from licensees and industry organizations. Canada’s national reports are published together with responses to questions received from other Contracting Parties. All Canadian national reports can be found on the CNSC’s website. Canada’s sixth national report was submitted in October 2017 and was presented at the Sixth Review Meeting in May 2018. CNSC staff will present the outcome of the Joint Convention to the Commission in fall 2018.

4 Regulatory developments

This section provides details of the regulatory developments of 2017 relating to regulatory programs for licensees covered in this report.

4.1 Licence application guide

In May 2017, REGDOC-1.6.1, Licence Application Guide: Nuclear Substances and Radiation Devices , Version 2 was published. The document provides applicants with guidance on completing and submitting an application for a nuclear substance and radiation devices licence. This revision includes changes to areas of the document that CNSC staff and applicants identified as needing clarification. The changes include:

- the addition of graphic warnings for information that should not be submitted by email (dose information, security information, social insurance numbers)

- an update to the financial guarantee information

- improvements to the forms associated with the licence application guide in order to reduce repetition of information required by the applicant and to automatically add the licence number to all pages of the forms

4.2 Certification of prescribed equipment

REGDOC-2.5.7, Design, Testing and Performance of Exposure Devices, was published in August 2017. The document provides guidance on the design, testing and performance of exposure devices in order to apply for certification of the device.

The regulatory document supersedes RD/GD-352, Design, Testing and Performance of Exposure Devices. The changes to the document were administrative in nature.

4.3 Exposure device operators

In 2017, there were two significant regulatory developments affecting exposure device operators (EDOs). They are described briefly below.

REGDOC-2.2.3, Personnel Certification: Exposure Device Operators, was published in March 2017. The document provides a reference to CSA PCP‑09, which documents the CNSC’s requirements and guidance for certification as an EDO. This regulatory document supersedes G-229, Certification of Exposure Device Operators.

With the first full cycle of renewals of exposure device operators completed in 2016, the Canadian Nuclear Safety Commission (CNSC) clarified its position with all industrial radiography licensees that workers are only considered qualified if they have a valid EDO certification card, that is, an EDO certification card issued on or after February 1, 2013 that has not expired. As a result, any EDO whose certification card either does not have an expiry date or has expired will not be qualified to work as a certified EDO as of January 1, 2017, and may be subject to enforcement actions.

4.4 Radiation safety officers

In 2017, CNSC staff started reviewing the oversight process of RSOs who are appointed (i.e., those who do not need to sit and pass an examination) in order to identify factors that may lead to greater success in that position. This process will be undertaken using internationally accepted methods and will be designed with the assistance of experts from within and outside the CNSC. It is anticipated that results from the review will be included in a regulatory document that will provide those performing the role of RSO with greater guidance on the CNSC’s expectations for individuals occupying the position of RSO.

4.5 Regulatory focus in 2018

The CNSC’s focus in 2018 continues to be on effective regulatory oversight and continuous improvement. Activities that will be undertaken in 2018 include:

-

verifying the implementation of the requirements in REGDOC‑2.12.3,

Security of Nuclear Substances: Sealed Sources, which came into force on May 31, 2018 for Category 3, 4

and 5 sealed sources (REGDOC‑2.12.3, has been in force for Category 1 and 2 sealed sources since 2015)

- proactively engaging with licensees that will be affected to prepare them for any changes to requirements that will take effect on that date

- continuing the strategy for enhancing the oversight of radiation safety officers and radiation protection programs for nuclear substance and radiation device licensees that was presented to the Commission in October 2017

- rolling out an information program targeting portable gauge users, including an updated user booklet and a safety video that have been developed to address the trends of decreasing compliance and the relatively high number of events, relative to other subsectors

- continuing to monitor the regulatory framework and regulatory practices to ensure that they remain appropriate, agile and sufficient to effectively regulate new technologies, new applications of existing technologies and new types of prescribed equipment

-

developing the first revision of CSA Group document CSA PCP-09,

Certified Exposure Device Operator Personnel Certification Guide

- The revised document will be distributed to the industry stakeholders for review and comments prior to its implementation

-

finalizing the following regulatory documents, which were posted for public comment in 2017 and are expected to

be published in 2018:

- REGDOC-1.4.1, Licence Application Guide: Class II Nuclear Facilities and Prescribed Equipment

- REGDOC-1.5.1, Licence Application Guide: Certification of Radiation Devices or Class II Prescribed Equipment

- REGDOC-2.1.2, Safety Culture

- REGDOC-2.5.5, Design of Radiography Installations

- REGDOC-2.7.3, Radiation Protection Guidelines for Safe Handling of Decedents

5 Safety performance – all sectors combined

This section provides an overview of the overall performance of the industry sectors covered in this report.

5.1 Overall safety assessment

Canadian Nuclear Safety Commission (CNSC) staff conducted 944 inspections across all sectors in 2017 to verify compliance with CNSC regulatory requirements, including 160 security inspections to verify enhanced security requirements applicable to Category 1 and 2 sealed sources. All sectors continued to demonstrate adequate performance within all safety and control areas (SCAs). The majority of inspected licensees in 2017 were found to be compliant in the five SCAs covered in this report:

- In management system, 97% of the licensees inspected ensured that adequate processes and programs were in place to achieve their safety objectives.

- In operating performance, 85% of the licensees inspected made adequate provisions for the health, safety, security, and protection of the environment.

- In radiation protection, 85% of the licensees inspected had measures and programs in place to ensure that exposure to workers and the public to ionizing radiation was monitored, controlled and remained ALARA (as low as reasonably achievable).

- In security, 90% of the licensees inspected demonstrated that they have adequate provisions in place to prevent the loss, sabotage, illegal use, illegal possession or illegal removal of sealed sources and prescribed equipment in their care and control.

- In environmental protection, 100% of waste nuclear substance licensees continue to manage and monitor environmental releases resulting from licenced activities. Releases were kept well below regulatory limits and there were no unplanned releases to the environment as a result of licensed activities (section 10).

REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources, added new requirements for security of sealed sources. Phase I of the implementation plan for the regulatory document focused on Category 1 and 2 sealed sources, and came into force for those licensees in May 2015. Since then, security inspections of licensees in possession of high-risk sealed sources have verified compliance with the requirements in REGDOC‑2.12.3. In 2017, 73% of inspected licensees (117 of 160 inspections) were found to be compliant with the requirements of REGDOC‑2.12.3. This is a slight decrease compared to the level of compliance in 2016. The majority of non-compliances for security requirements were related to deficiencies in the site security plan, non-effective physical barriers for storage locations and inadequate measures of access control. Licensees have put in place measures to correct all non-compliances identified during these inspections. To date, all licensees with Category 1 and 2 sealed sources have been inspected, although not all work locations have been inspected.

Doses for 53,351 workers were reported to the CNSC in the five sectors covered in this report. Of those workers, 19,185 were designated as nuclear energy workers (NEWs), while 34,166 were not.

There was one instance of overexposure in 2017. A nuclear medicine technologist received a dose to the skin of the hand that was above regulatory limits. Additional information is provided in the sections on the medical sector (section 6.3.1).

For 2017, CNSC staff assessed all 146 events reported by the licensees covered in this report. Reported events have been ranked using the International Nuclear and Radiological Event Scale (INES). Of these, 144 were ranked as level 0 (no safety significance), 1 was ranked as level 1 (anomaly) and 1 was ranked as level 2 (incident).

For all of the events reported, licensees implemented appropriate response measures to mitigate the impacts of the events and to limit radiation exposure to workers and the public. CNSC staff reviewed the measures put in place by licensees and found them to be satisfactory.

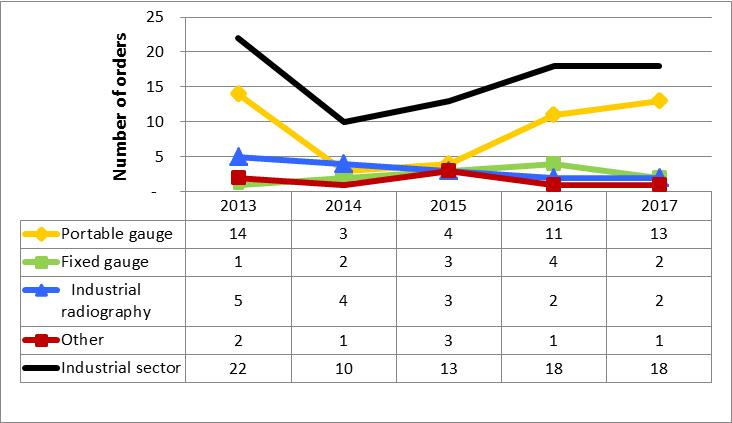

In 2017, 12 inspections of a total of 10 licensees received a rating of unacceptable in at least one SCA. Seven of the licensees were portable gauge licensees, considered a medium-risk activity. One licensee was in the industrial radiography sector, considered a high-risk activity, one was involved with fixed gauges (a medium-risk activity) and one did servicing (a medium-risk activity). The CNSC took escalated enforcement actions, issuing an order, an administrative monetary penalty (AMP) or both, in all but one case. Additional details about enforcement actions can be found in section 5.6. All orders are closed. All but one AMP have been paid.

5.1.1 Licensees with compliance ratings below expectations

The CNSC takes a licensee’s compliance history into account when determining the inspection schedule. When a licensee repeatedly performs below expectations, the CNSC may increase the regulatory oversight of the licensee. This could include additional reactive inspections to monitor ongoing compliance or increased inspection frequency. The CNSC reviewed the past performance of licensees that had poor ratings in at least one SCA in 2017; 21% of these licensees (11 out of 53) were rated below expectations or unacceptable in the same SCA in their previous inspection. All were medium-risk licensees. In all cases, CNSC inspectors tracked the items of non-compliance until they were addressed by the licensee in a manner that was satisfactory to CNSC staff. The poor performance of these licensees was considered when determining the inspection plan for the fiscal year 2018/19.

5.2 Management system

The management system SCA covers the framework that establishes the processes and programs required to ensure that an organization achieves its safety objectives, continuously monitors its performance against those objectives and fosters a healthy safety culture.

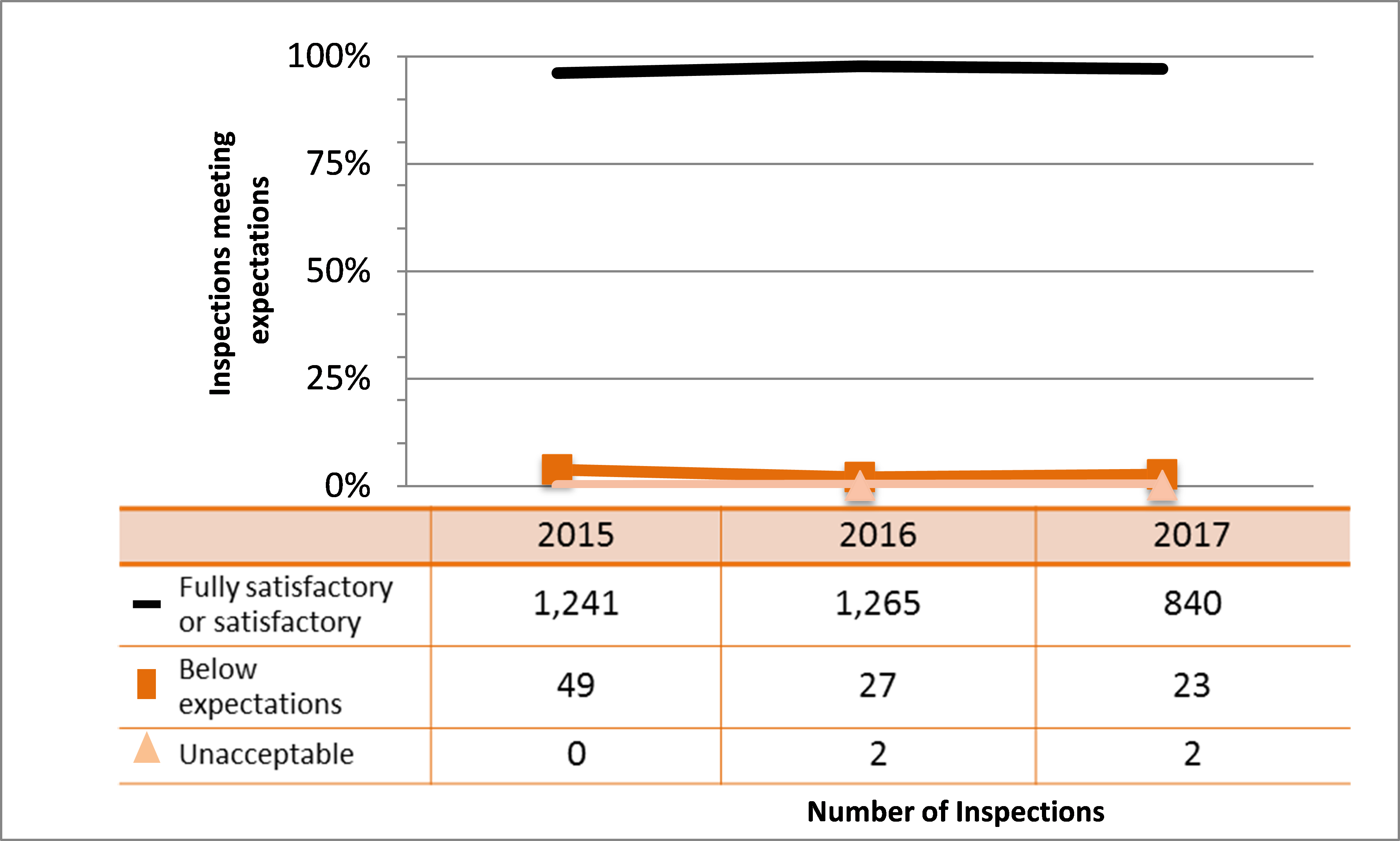

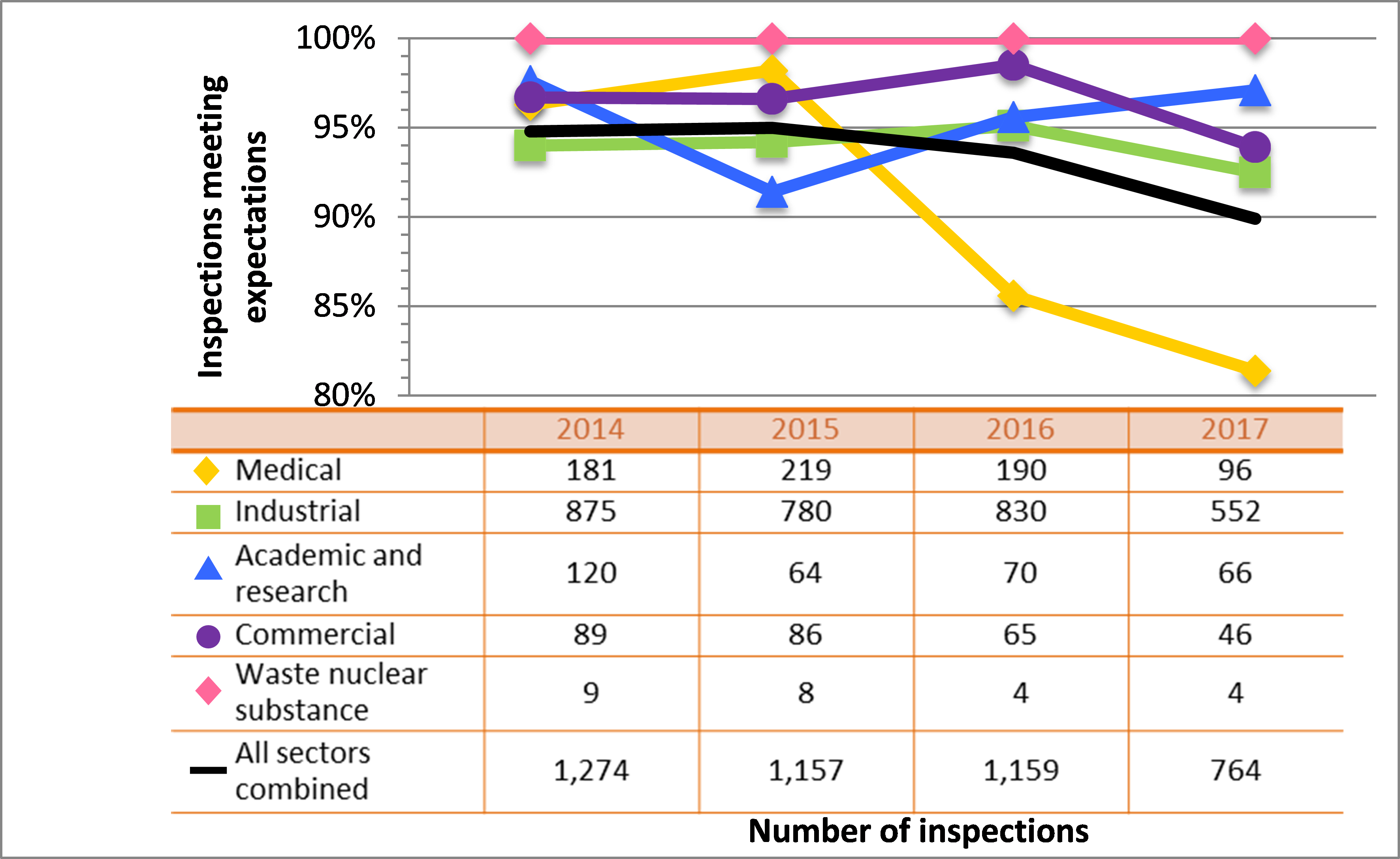

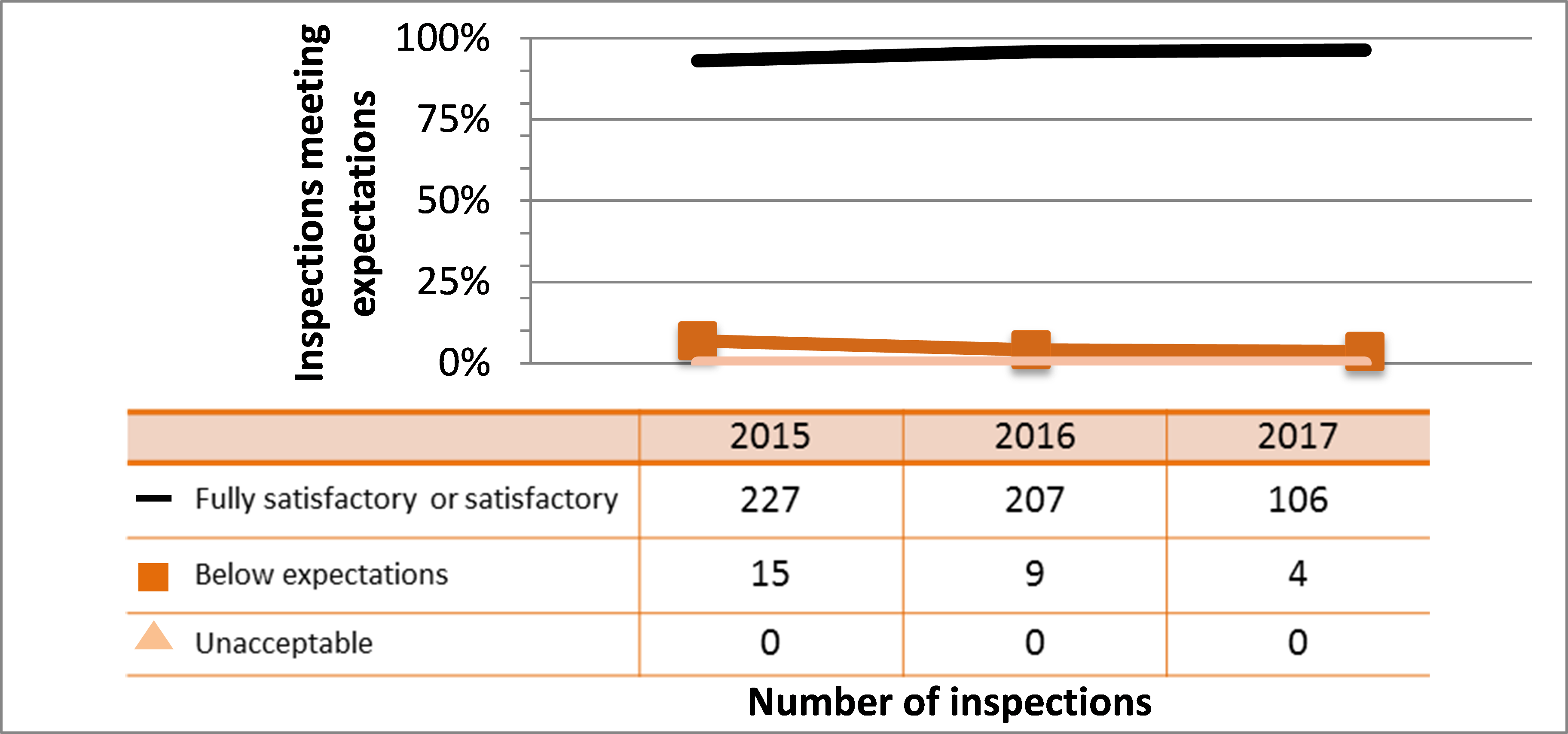

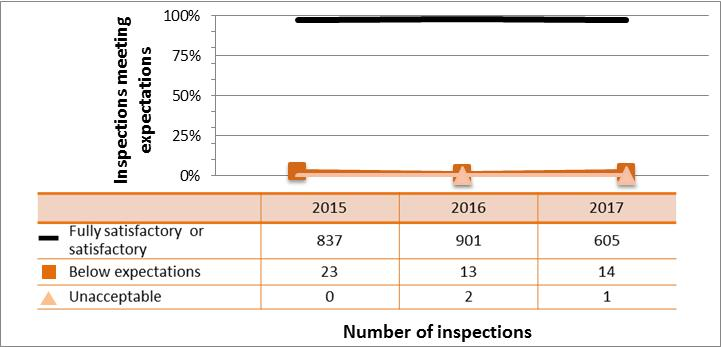

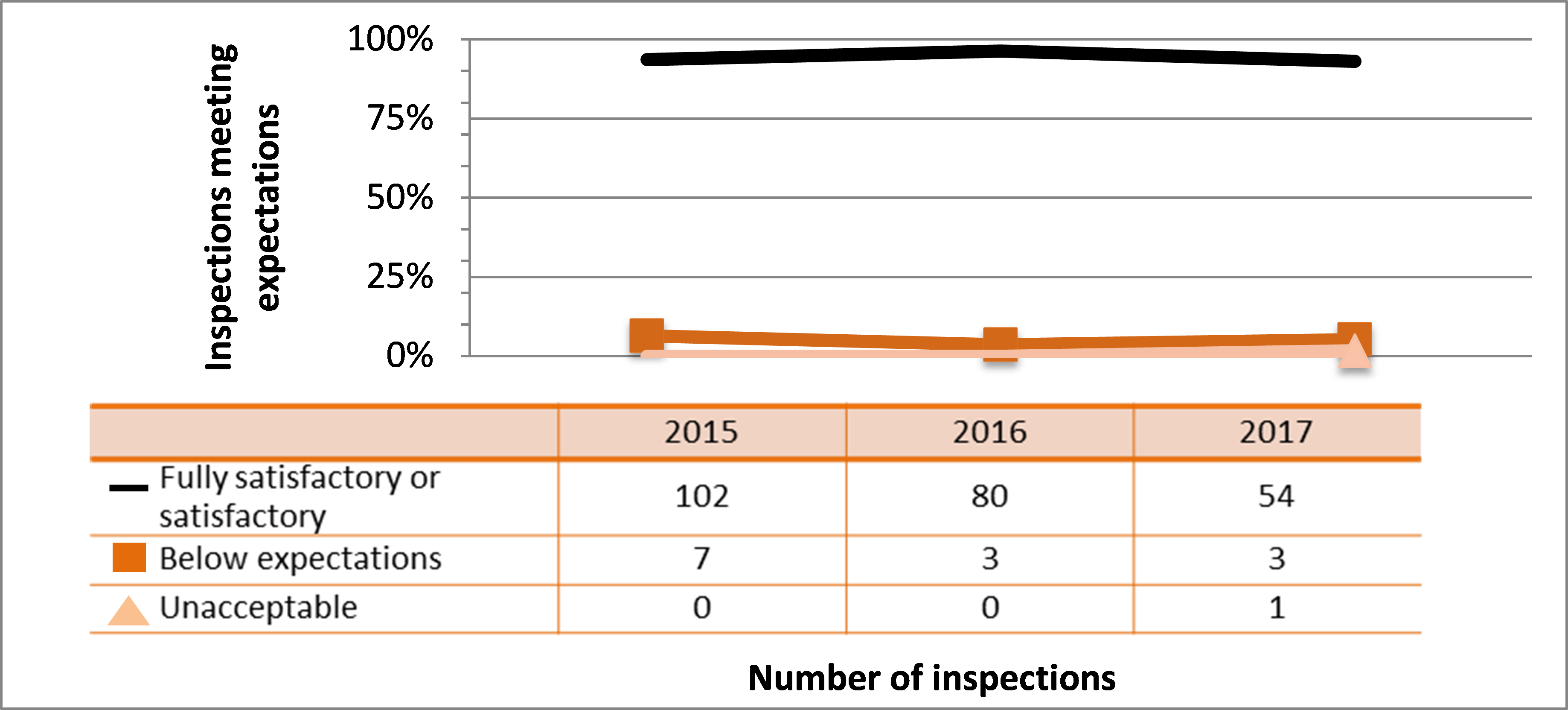

All sectors demonstrated satisfactory performance within the management system SCA, with 97% of inspected licensees (840 of 865 inspections) found to be in compliance with regulatory requirements (see figure 4). This is consistent with previous years. A breakdown of the inspection ratings by sector for 2017 is shown in figure 5.

Two inspections resulted in unacceptable ratings for the management system SCA for one licensee from the commercial sector and one licensee from the industrial sector. A CNSC inspector issued an order to the licensee from the industrial sector.

The majority of non-compliances in this SCA were the result of licensees failing to submit an annual compliance report as required; failing to keep required records at all work locations, including any temporary work locations; and conducting activities for which they were not licensed (generally, these items were administrative in nature, such as using nuclear substances not listed on their licences or possessing radiation device models that did not appear on their licences). CNSC staff tracked all items of non-compliance until the licensee addressed them in a manner that was satisfactory to the CNSC.

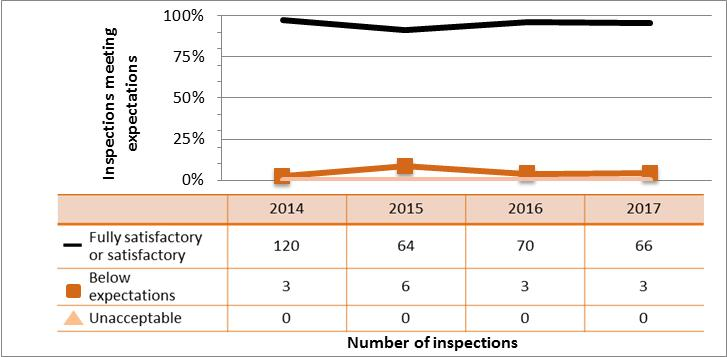

Figure 4: Inspection ratings for management system, 2015–17

Description

| Ratings | 2015 | 2016 | 2017 |

|---|---|---|---|

| Fully satisfactory or satisfactory | 1,241 | 1,265 | 840 |

| Below expectations | 49 | 27 | 23 |

| Unacceptable | 0 | 2 | 2 |

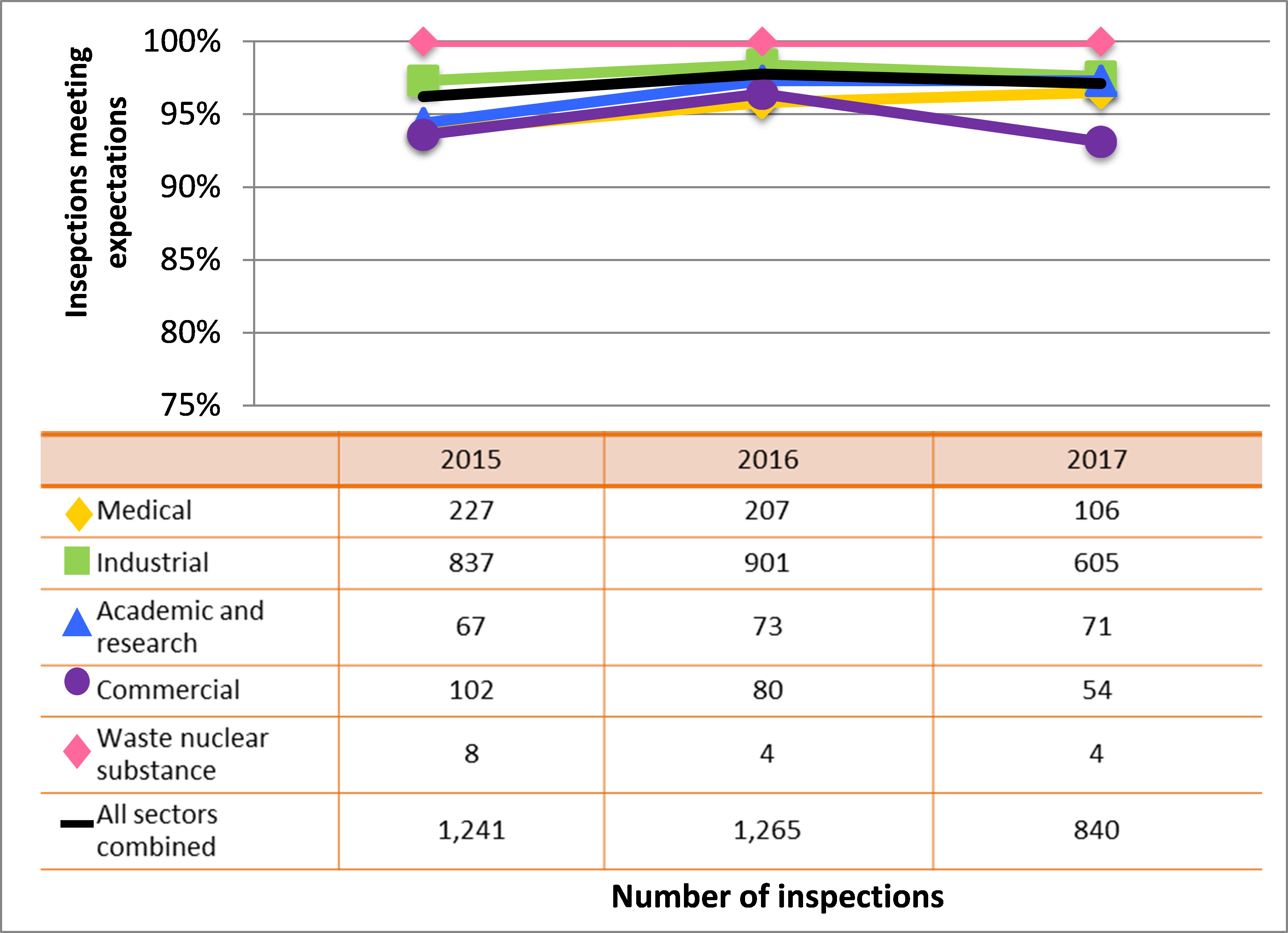

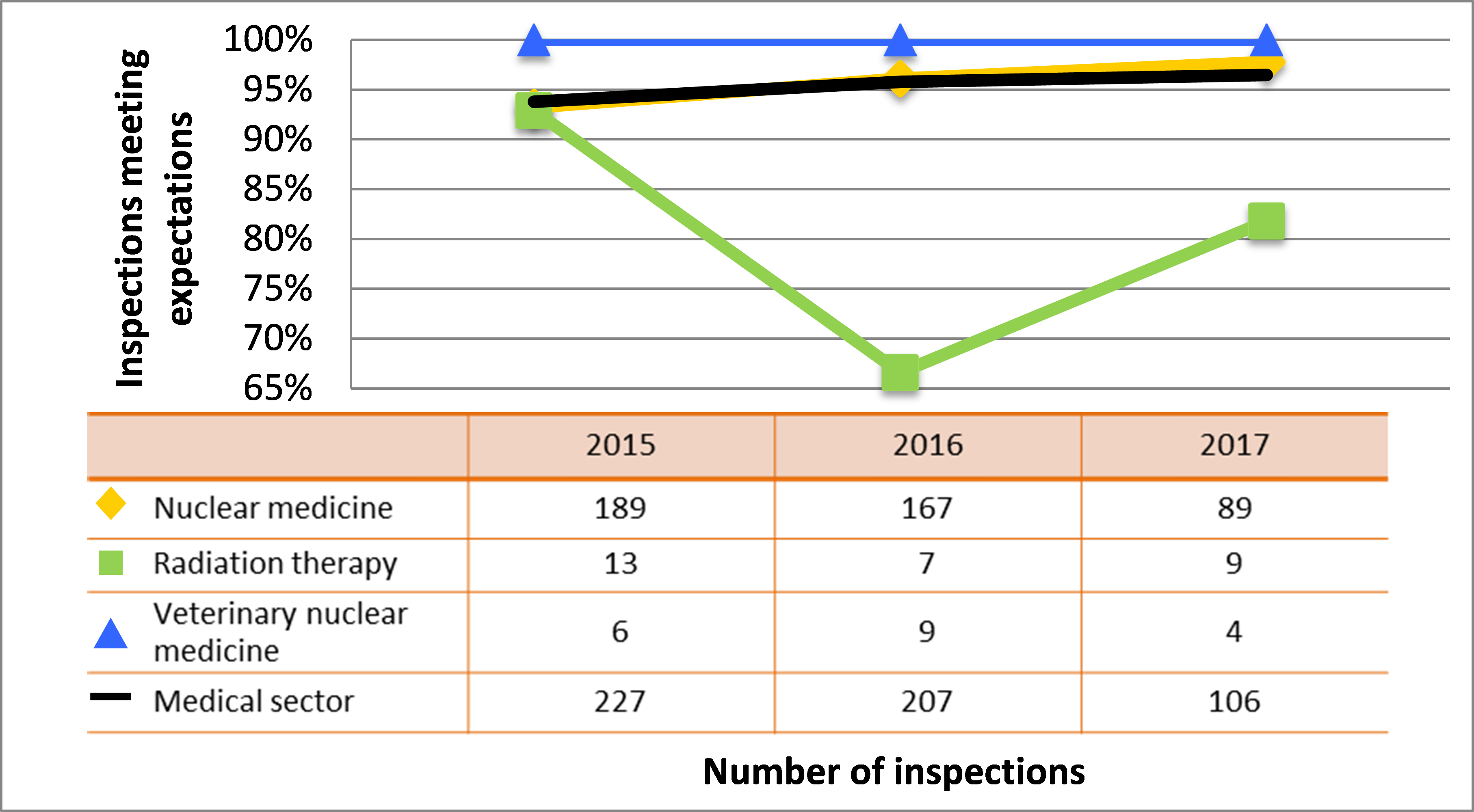

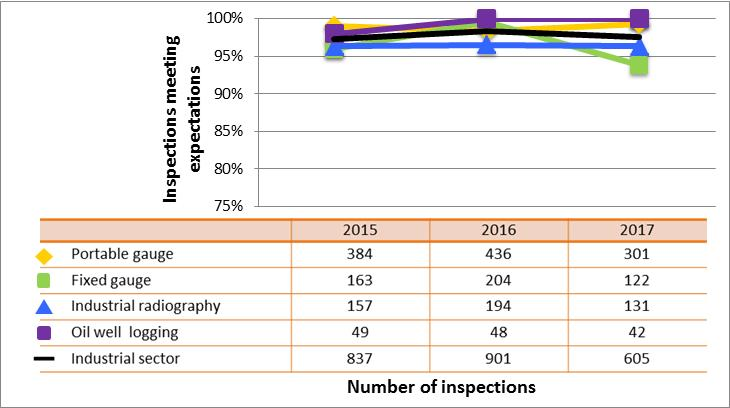

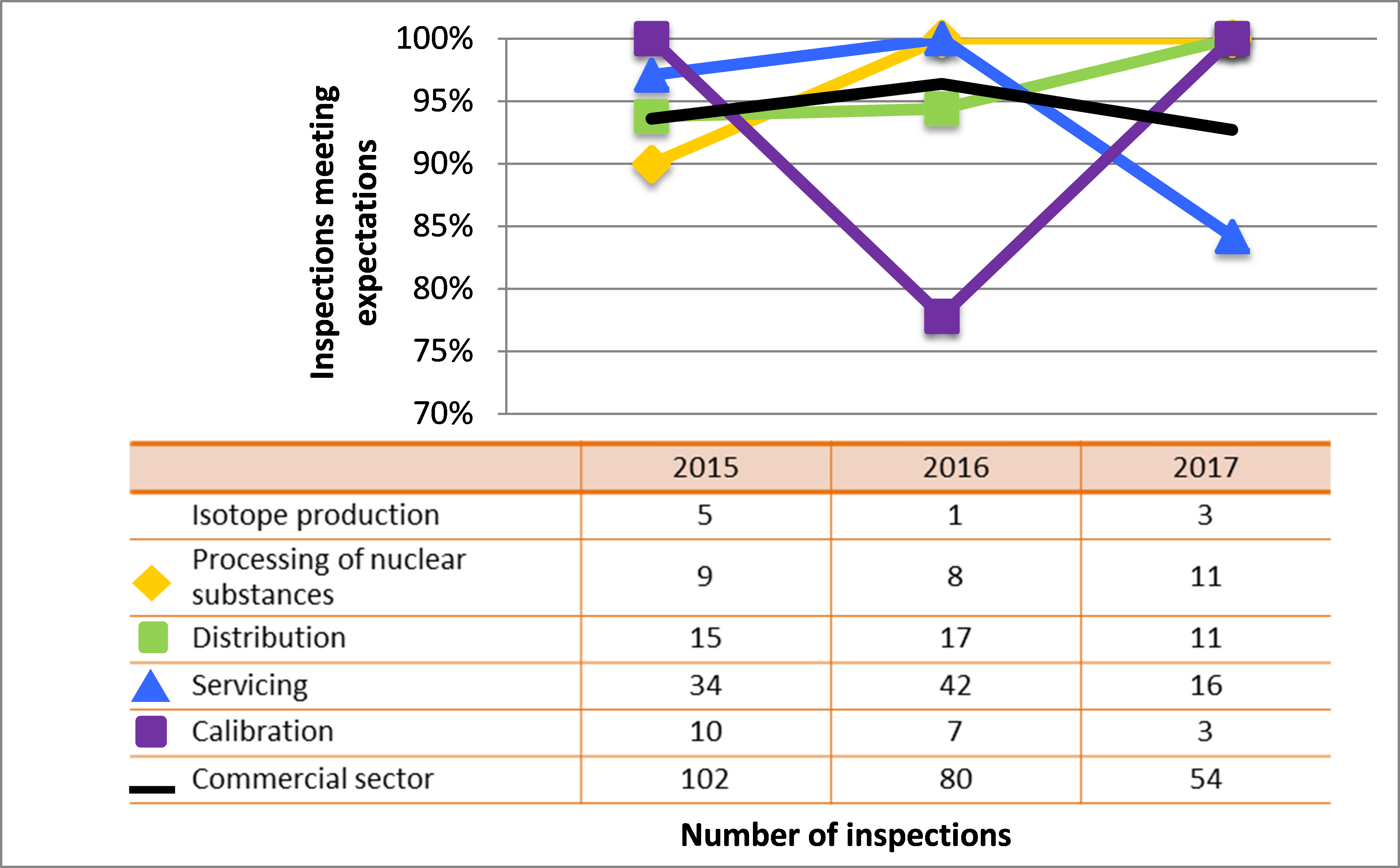

Figure 5: Sector-to-sector comparison of inspection ratings meeting or exceeding expectations for management system, 2015–17

Description

| Sector | 2015 | 2016 | 2017 |

|---|---|---|---|

| Medical | 227 | 207 | 106 |

| Industrial | 837 | 901 | 605 |

| Academic and research | 67 | 73 | 71 |

| Commercial | 102 | 80 | 54 |

| Waste nuclear substance | 8 | 4 | 4 |

| All sectors combined | 1,241 | 1,265 | 840 |

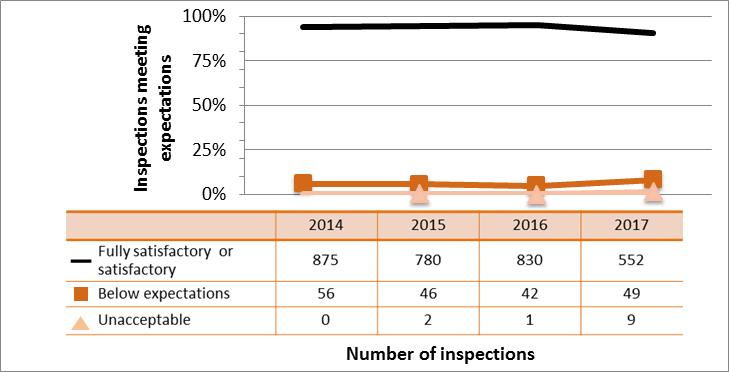

5.3 Operating performance

Operating performance refers to the licensee’s ability to perform licensed activities in accordance with pertinent operational and safety requirements defined in the Nuclear Safety and Control Act (NSCA), its associated regulations and licence conditions. Licensees are expected to demonstrate that they comply with operational and safety requirements by providing workers with appropriate procedures for the safe use of nuclear substances and prescribed equipment, by ensuring that workers follow procedures, and by maintaining records that demonstrate compliance.

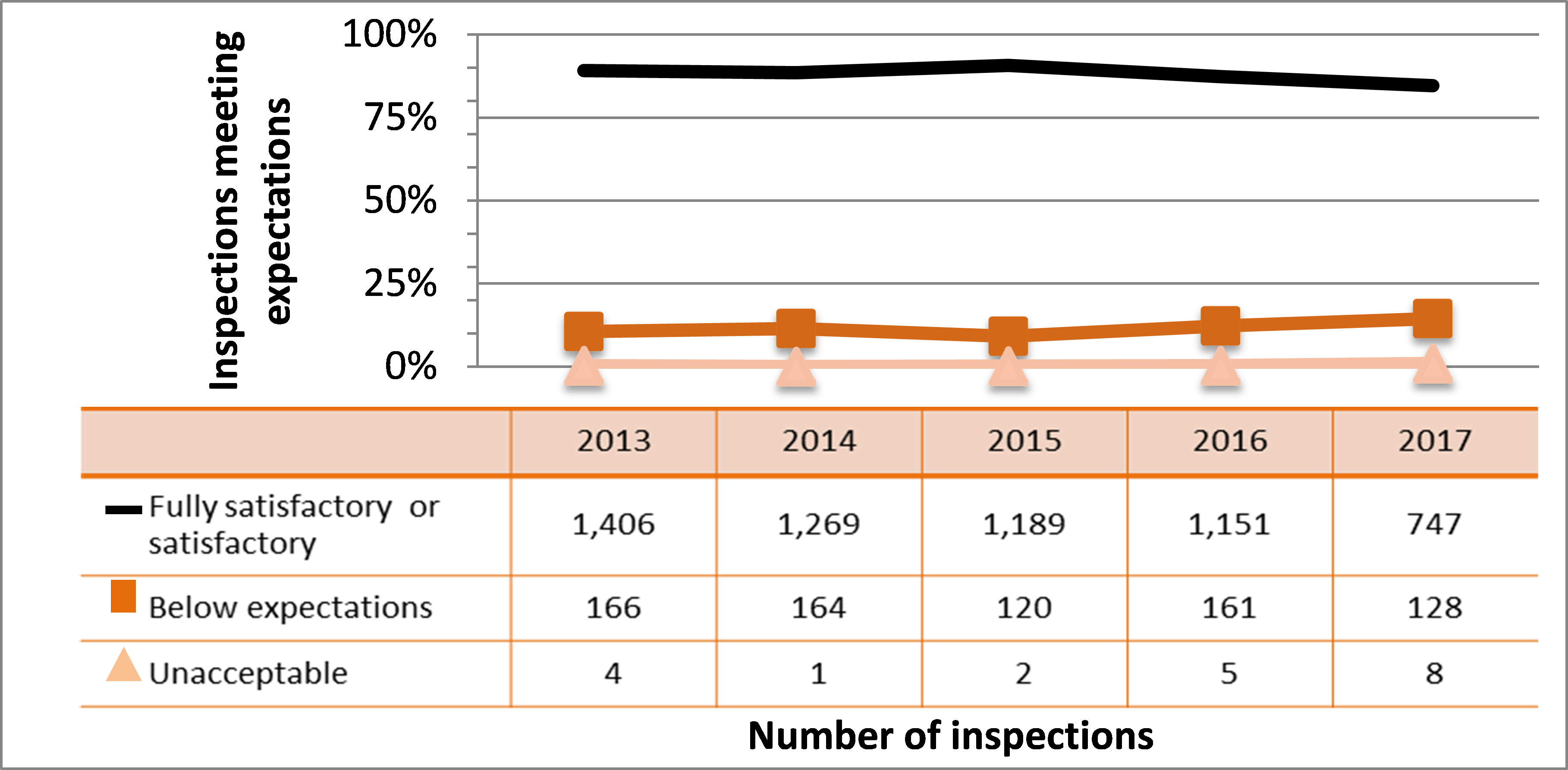

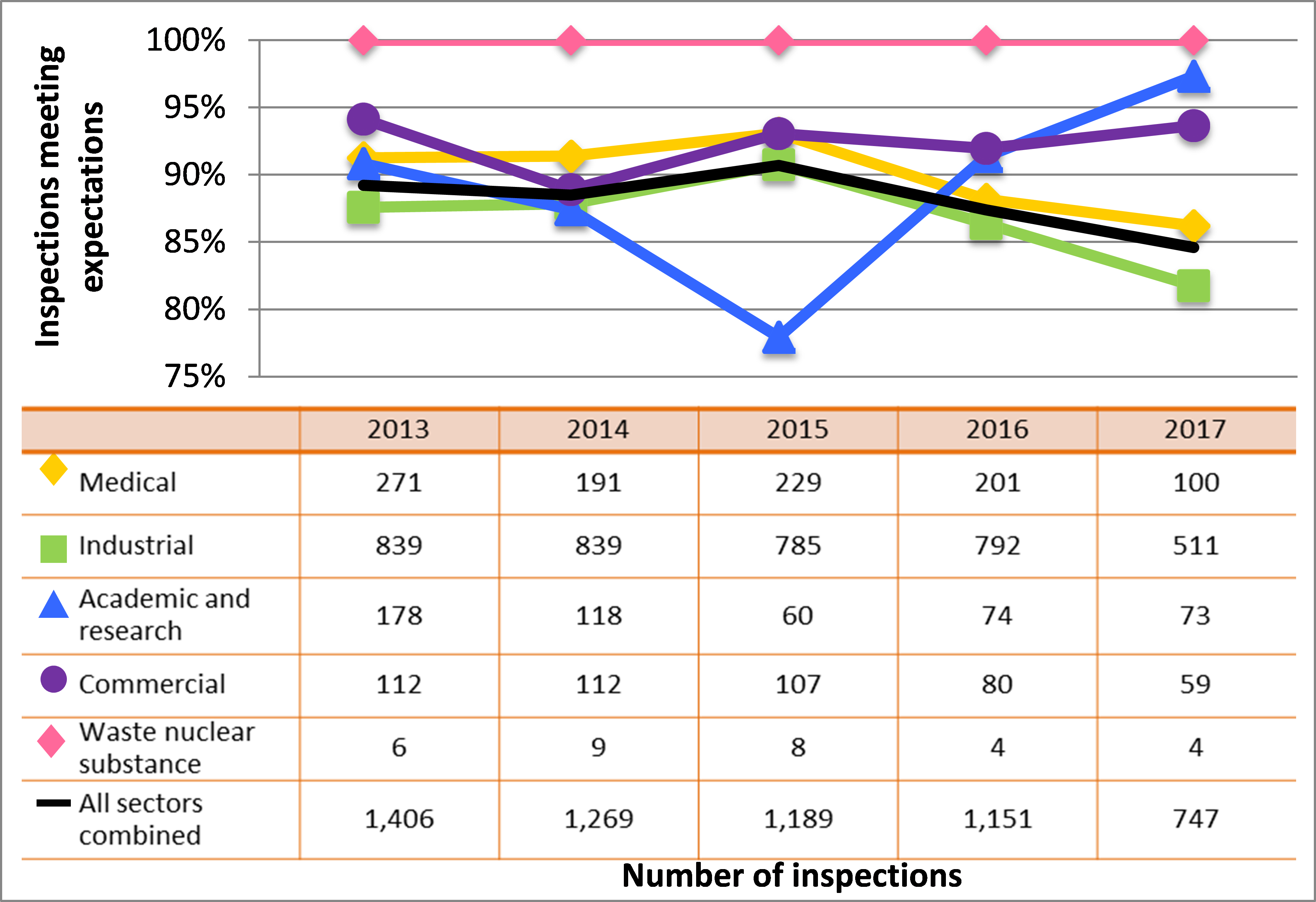

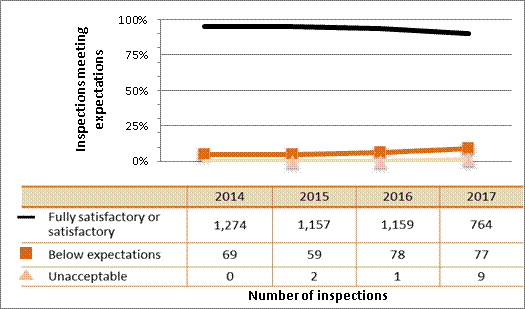

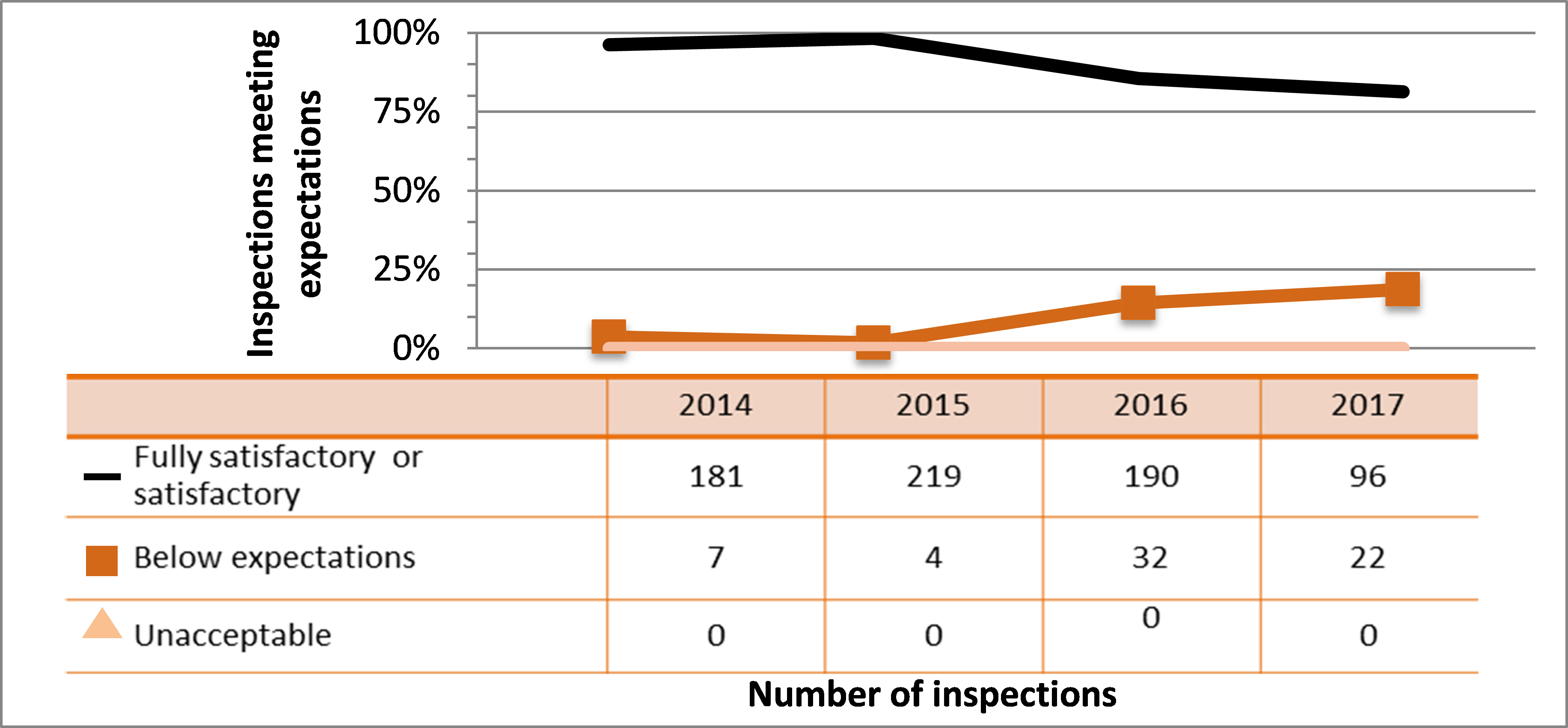

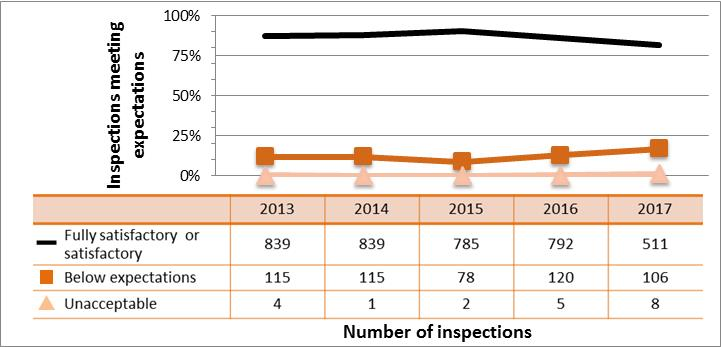

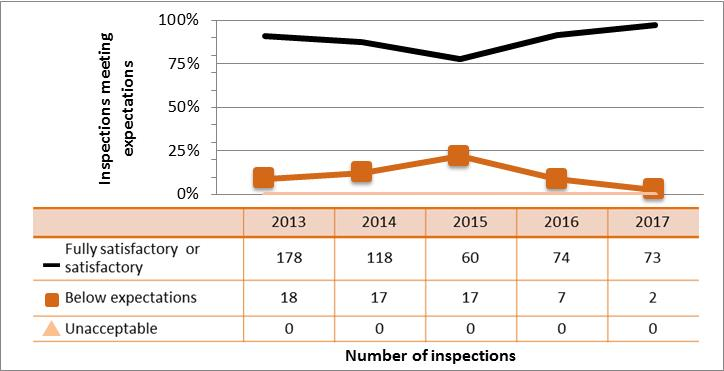

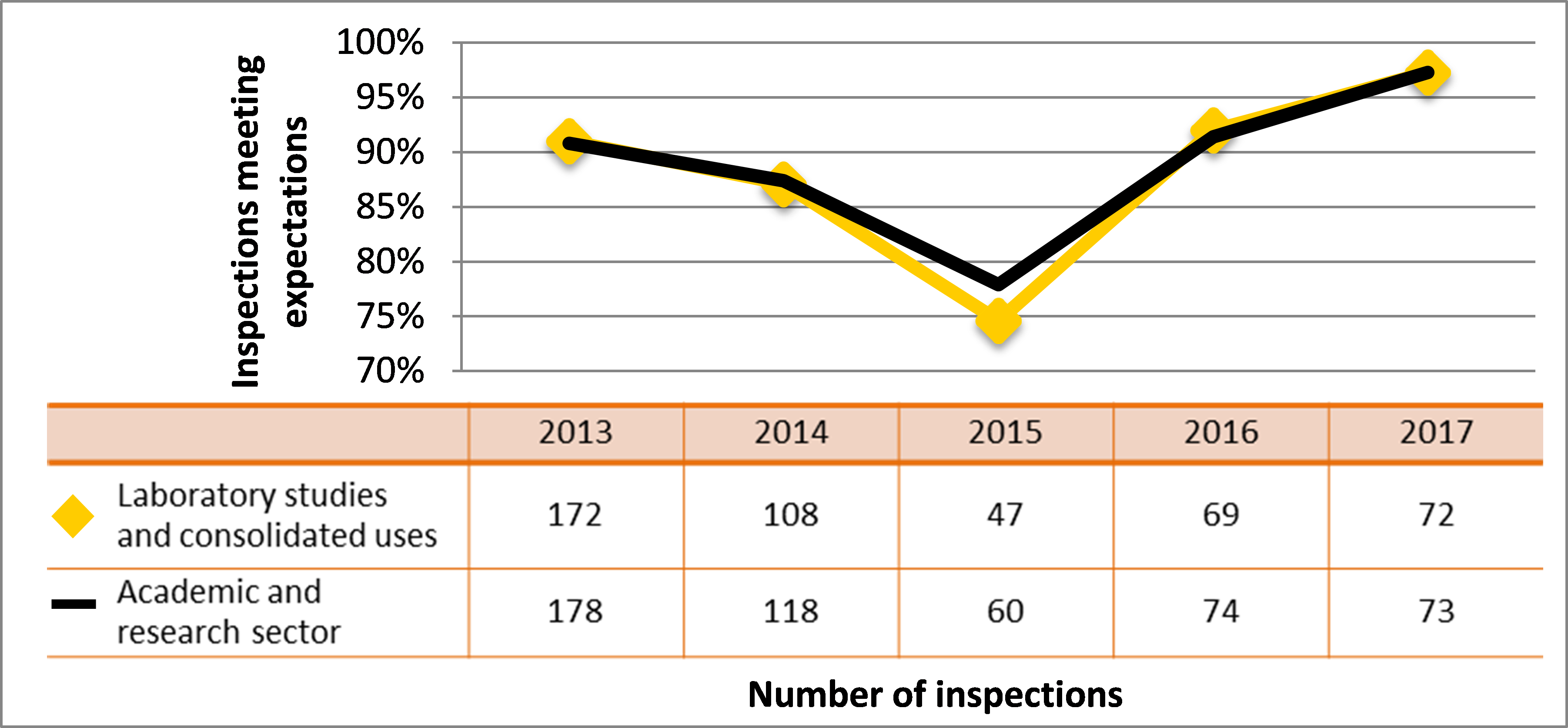

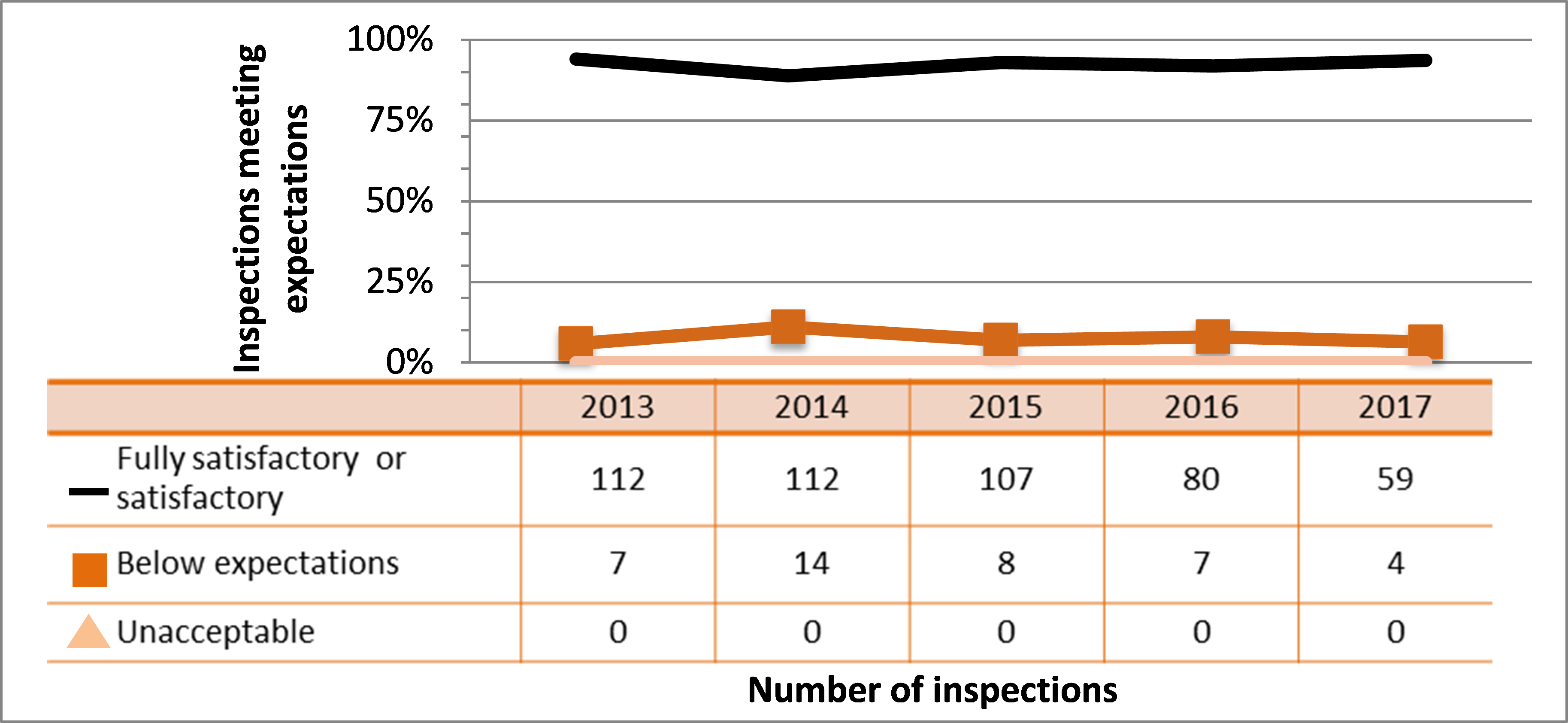

All sectors continued to demonstrate adequate performance within the operating performance SCA in 2017, with 85% of inspected licensees (747 out of 883 inspections) found to be in compliance with regulatory requirements. This continues a gradual downward trend in performance for this SCA. Specific projects are in place to address the decreasing performance in the medical and industrial sectors, are described in sections 4.4 and 7.3.3, respectively. These projects, the RSO and Radiation Protection Program Evaluation project, and initiatives targeting portable gauge users, aim to improve the performance across all SCAs.

Inspection ratings for all sectors combined are shown in figure 6, and a sector-to-sector comparison appears in figure 7. Performance of both the medical and industrial sectors dropped again in 2017, reducing overall performance in this SCA. The academic and research sector showed improved performance again in 2017. Its performance in this SCA has rebounded above where it was in 2013 when it started to decline.

Eight inspections resulted in a rating of unacceptable for the operating performance SCA in 2017. In all cases, inspectors issued orders to the licensees to stop the unsafe work practices and ensure corrective actions were taken immediately.

The most common non-compliances in this SCA included failure to comply with regulatory requirements related to workers’ responsibilities to follow licensee procedures and use equipment provided by the licensee, failure to follow the procedures in the documents appended to the licence, failure to keep training records for employees, and failure to conduct leak testing of sealed sources at the required frequency. CNSC staff tracked all items of non-compliance until the licensee addressed them in a manner that was satisfactory to the CNSC.

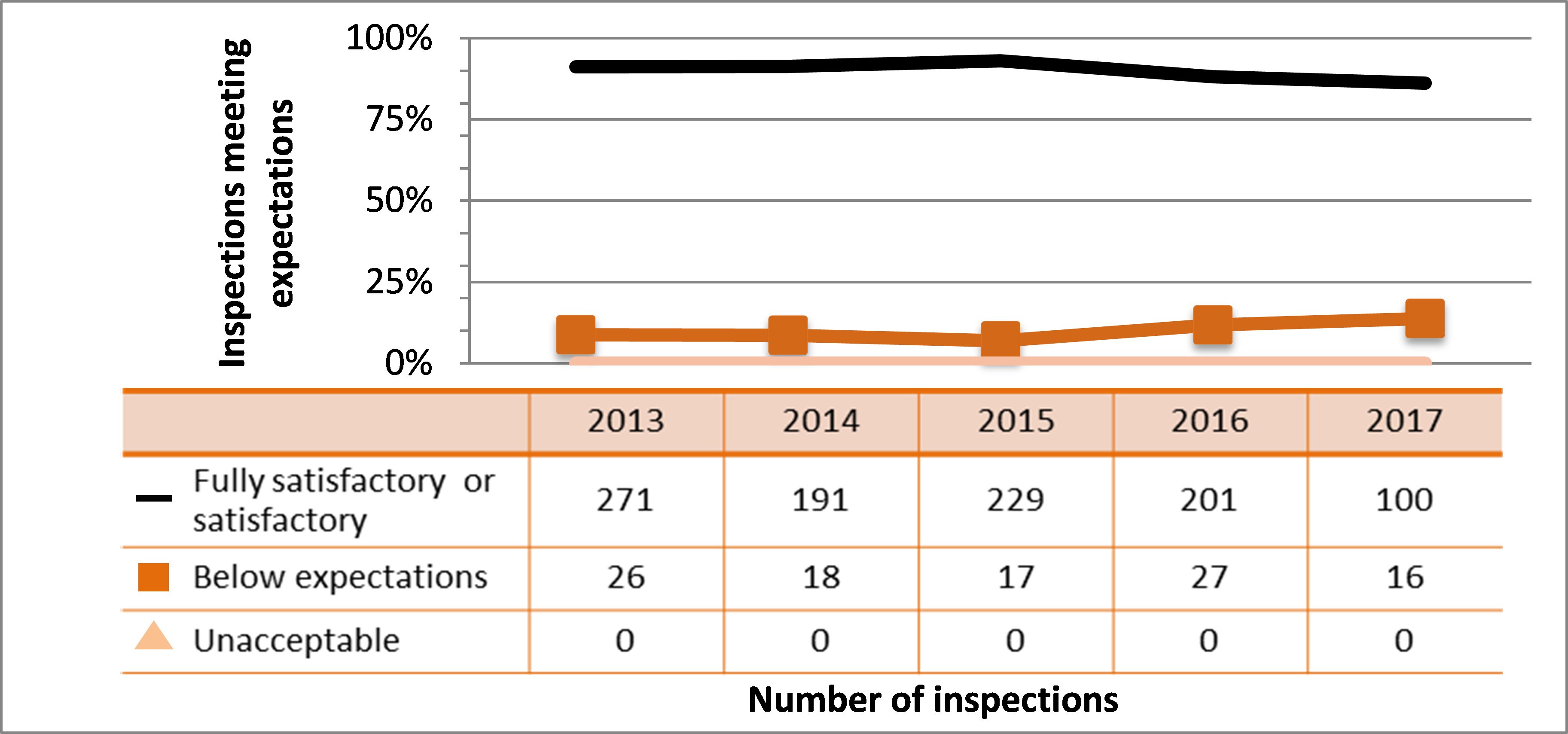

Figure 6: Inspection ratings for operating performance, 2013‒17

Description

| Rating | 2013 | 2014 | 2015 | 2016 | 2017 |

|---|---|---|---|---|---|

| Fully satisfactory | 1,406 | 1,269 | 1,189 | 1,151 | 747 |

| Below expectations | 166 | 164 | 120 | 161 | 128 |

| Unacceptable | 4 | 1 | 2 | 5 | 8 |

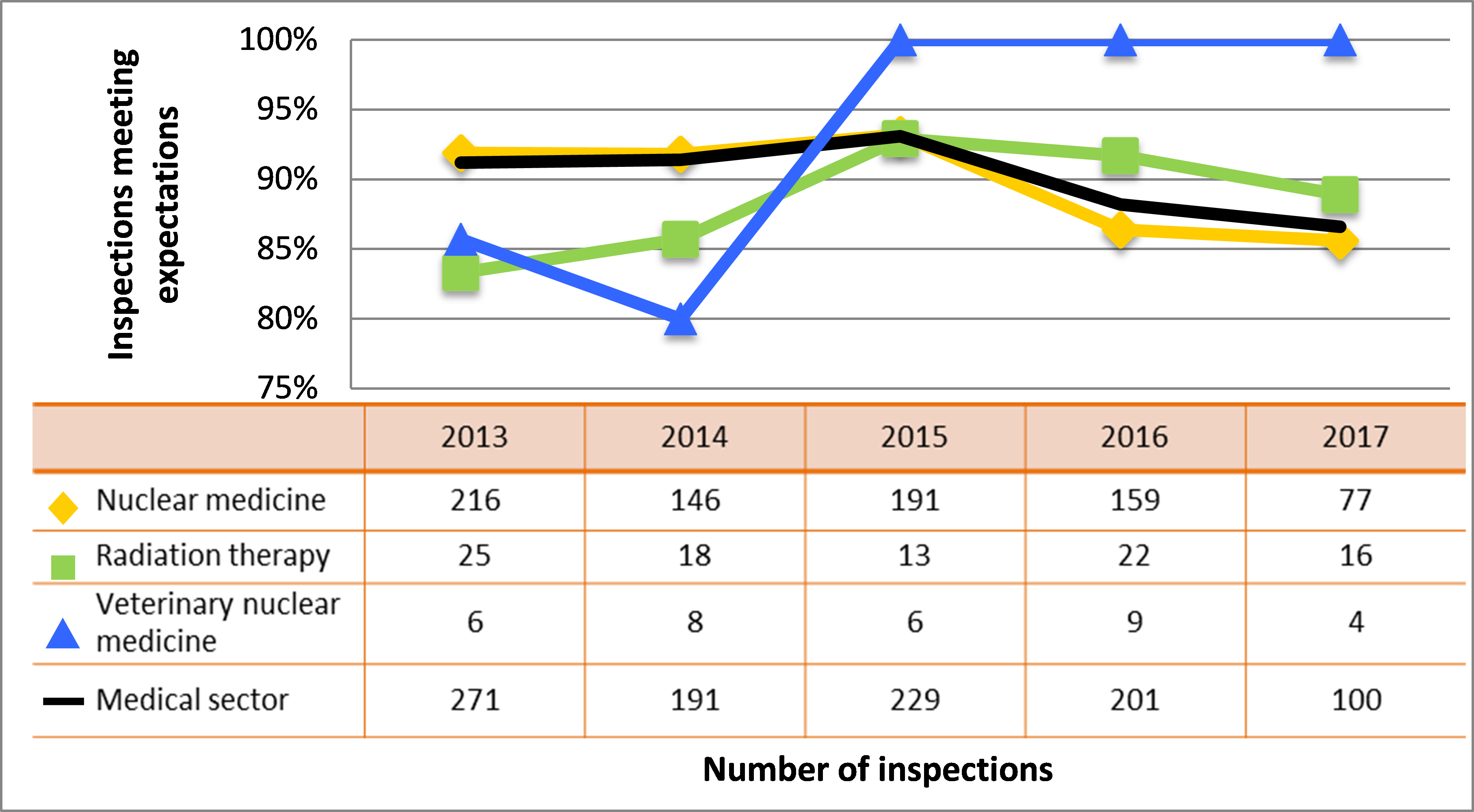

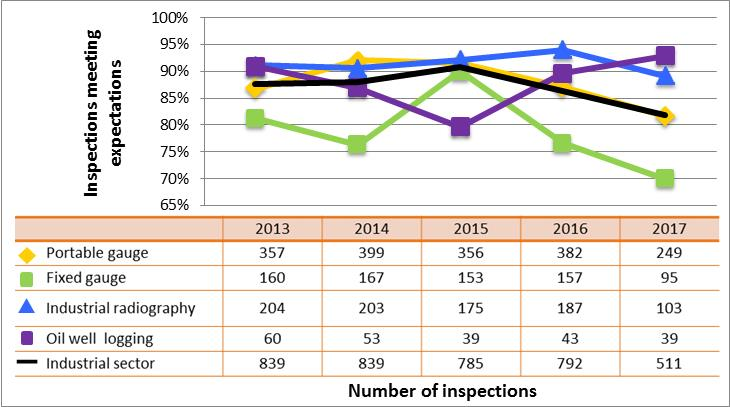

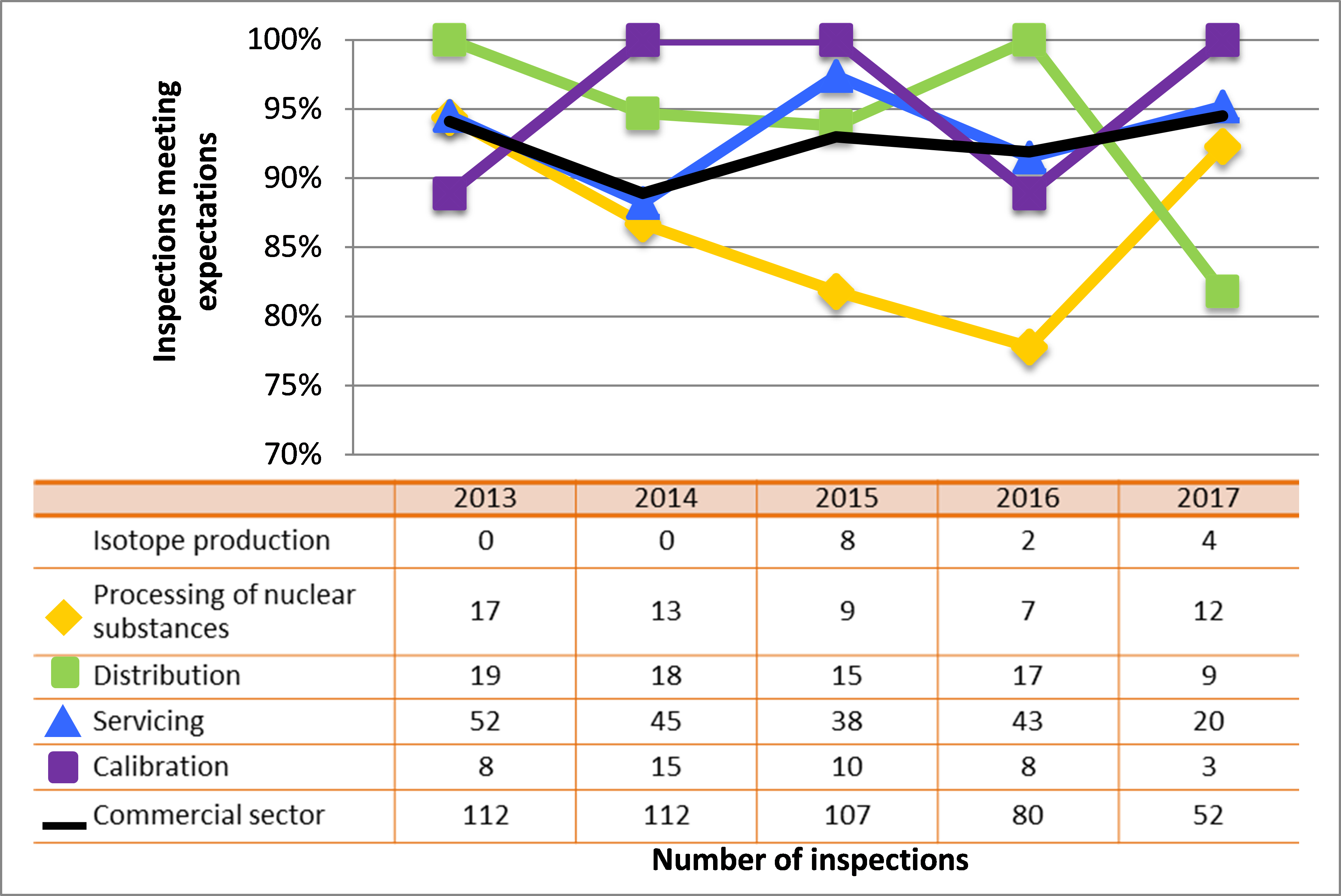

Figure 7: Sector-to-sector comparison of inspection ratings meeting or exceeding expectations for operating performance, 2013–17

Description

| Sector | 2013 | 2014 | 2015 | 2016 | 2017 |

|---|---|---|---|---|---|

| Medical | 271 | 191 | 229 | 201 | 100 |

| Industrial | 839 | 839 | 785 | 792 | 511 |

| Academic and research | 178 | 118 | 60 | 74 | 73 |

| Commercial | 112 | 112 | 107 | 80 | 59 |

| Waste nuclear substance | 6 | 9 | 8 | 4 | 4 |

| All sectors combined | 1,406 | 1,269 | 1.189 | 1,151 | 747 |

5.4 Radiation protection

Figure 8: Checking for contamination during an inspection (Source: CNSC)

Radiation protection programs are required for every licensee to ensure that contamination levels and radiation doses received by workers are monitored, controlled and maintained below regulatory dose limits, and kept at levels that are ALARA, social and economic factors being taken into account. Licensees are expected to monitor worker doses; post radiation warning signs; plan appropriately for radiological emergencies; manage oversight of operational activities; and institute effective workplace practices that emphasize the use of time, distance and shielding to minimize exposure to radiation, and emphasize the use of appropriate protective equipment.

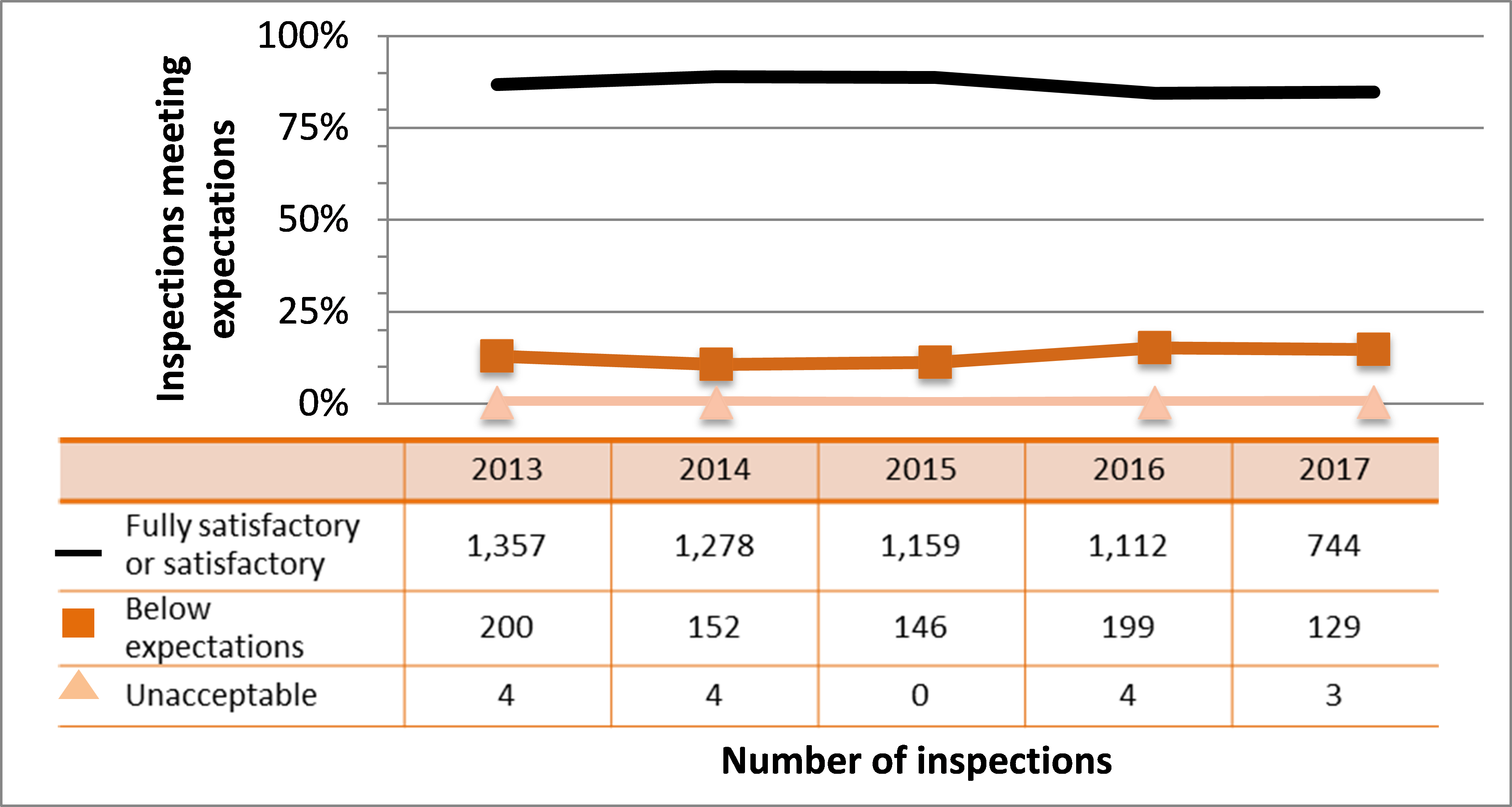

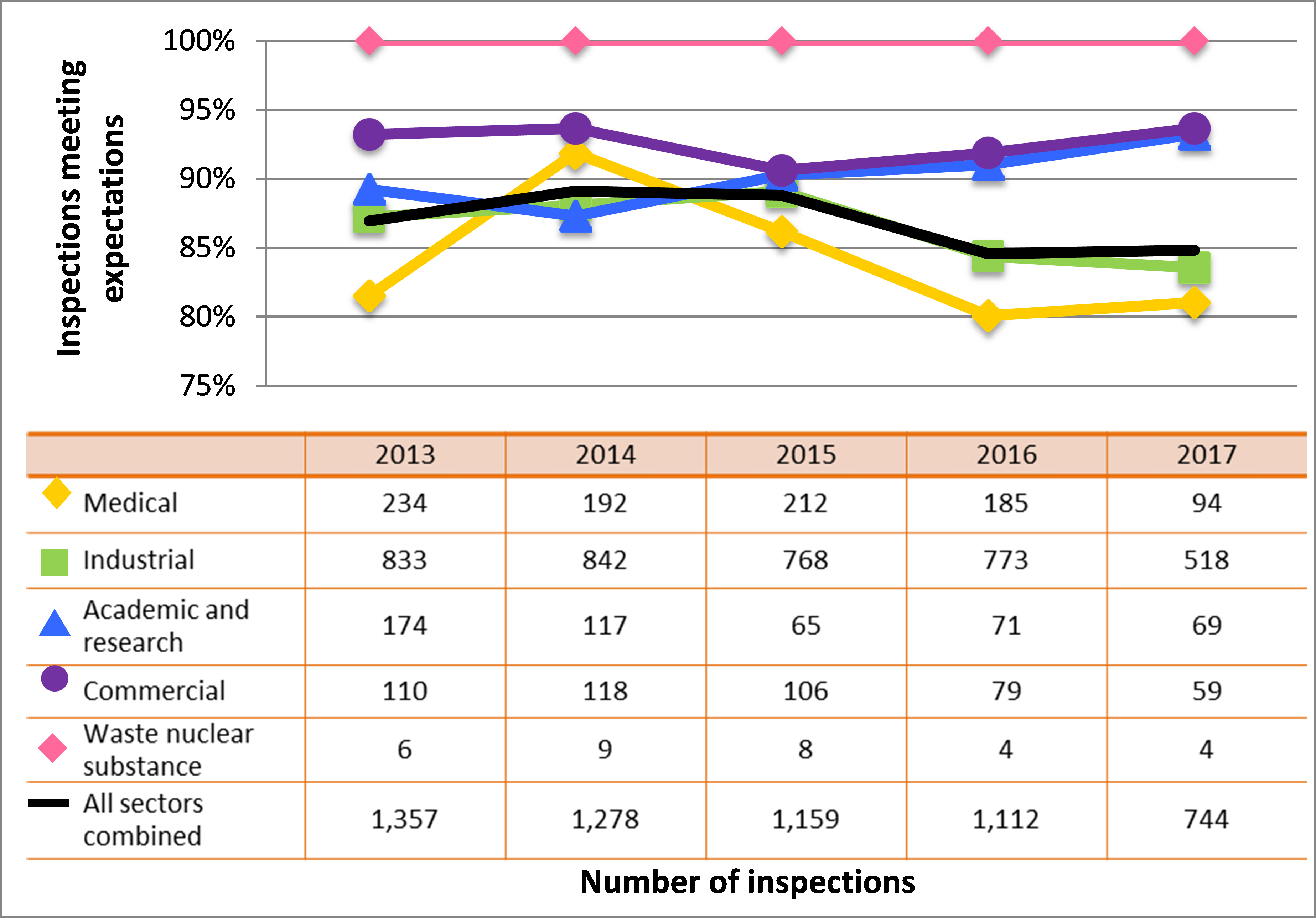

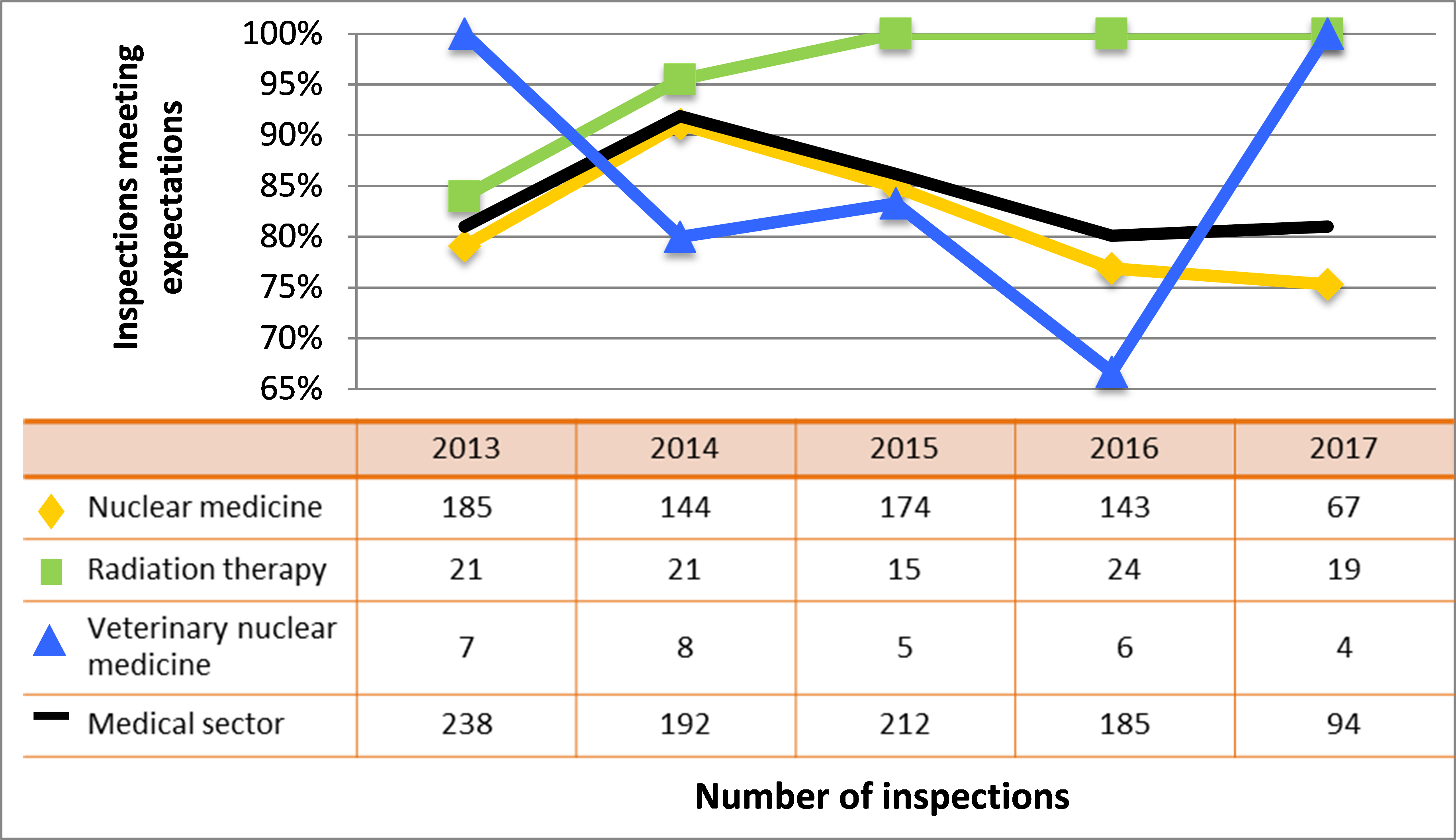

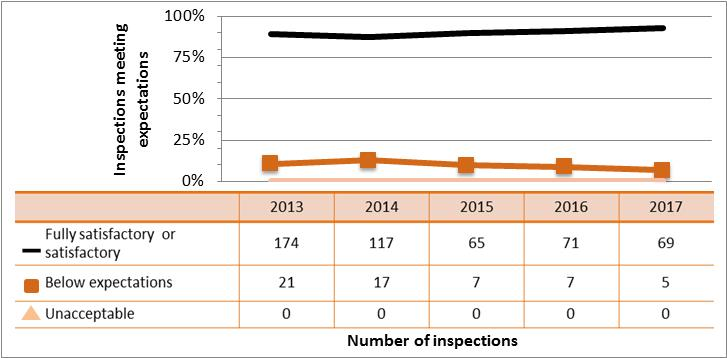

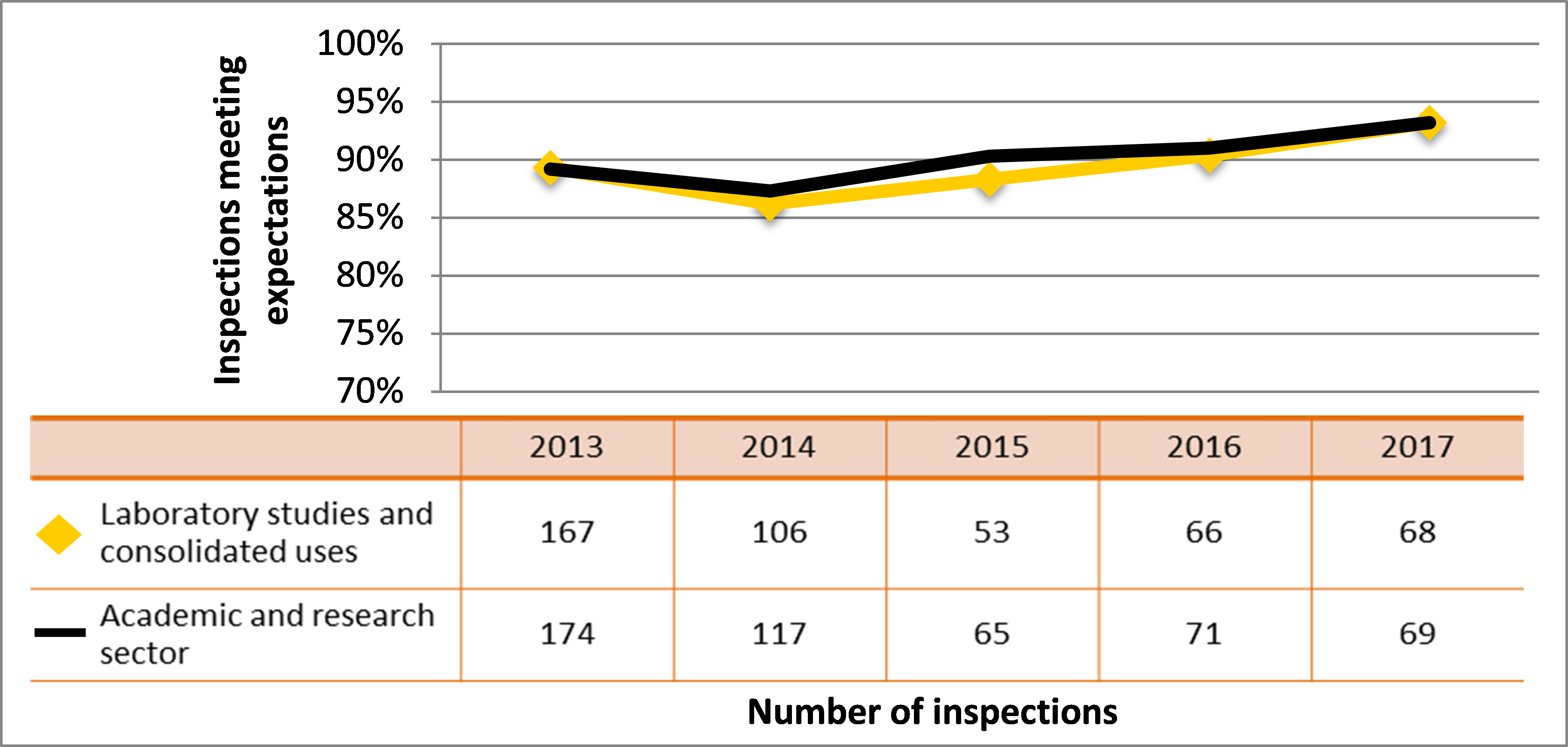

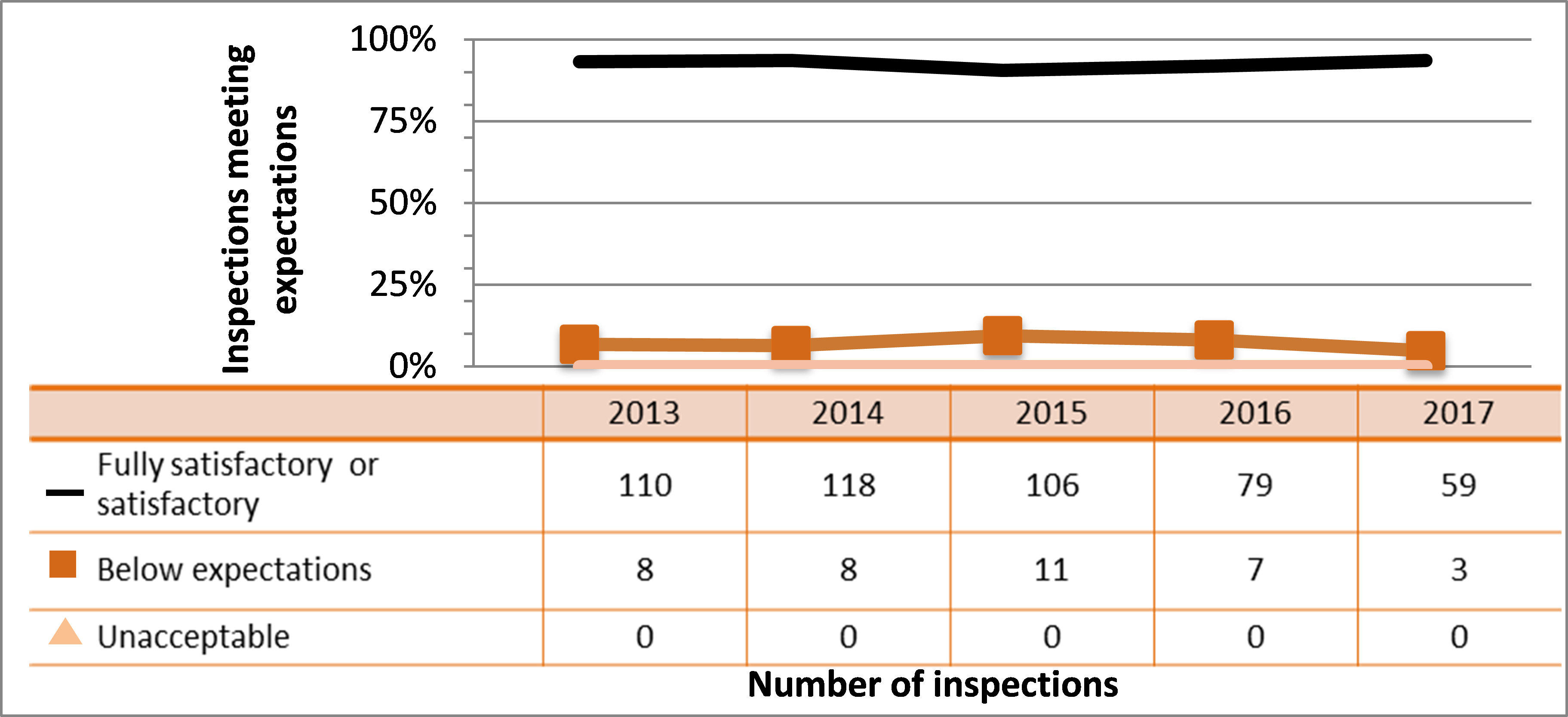

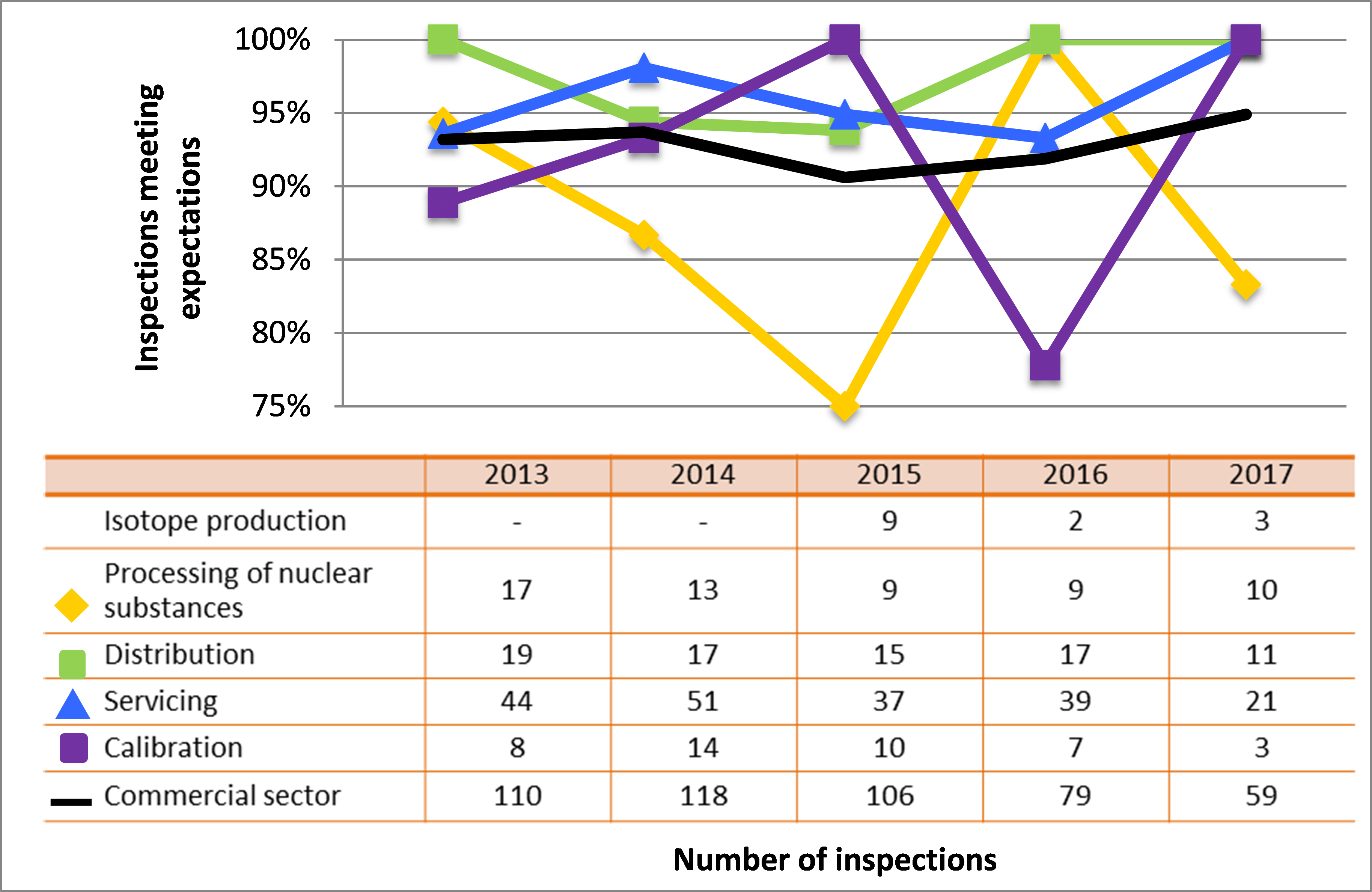

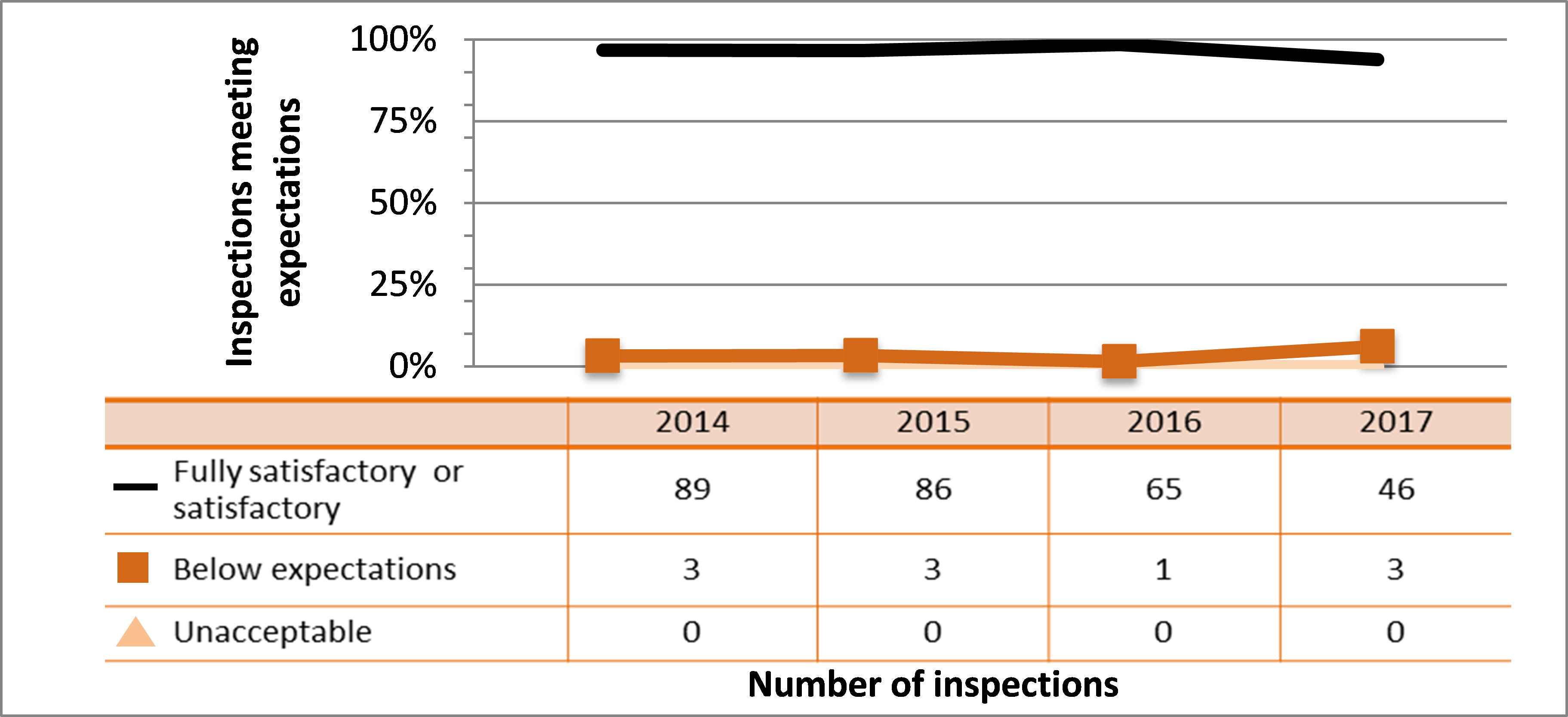

All sectors demonstrated adequate performance within this SCA, with 85% of inspected licensees (744 of 876 inspections) found to be compliant with regulatory requirements. However, this represents a lower level of compliance than has been observed since 2013. (See figure 9). The drop in performance in this SCA is driven by the medical and industrial sectors. Further details about measures being taken to improve the performance of these sectors can be found in sections 6.3 and 7.3, respectively.

In 2017, three inspections resulted in unacceptable ratings for radiation protection. Of these inspections, one also had an unacceptable rating for the operating performance SCA, and another one had an unacceptable rating for the management system SCA. In all three cases, the CNSC inspectors issued an order to immediately stop the unsafe work practices and to implement corrective measures.

Inspection ratings for all sectors combined are shown in a sector-to-sector comparison presented in figure 10.

The most common reasons for non-compliance were failing to implement radiation programs that keep doses to workers and the public ALARA, failing to post radiation warning signs as required, failing to limit access to storage areas to authorized workers and failing to keep the dose rate outside storage areas below the regulatory limit. CNSC staff tracked all items of non-compliance until the licensee addressed them in a manner that was satisfactory to the CNSC.

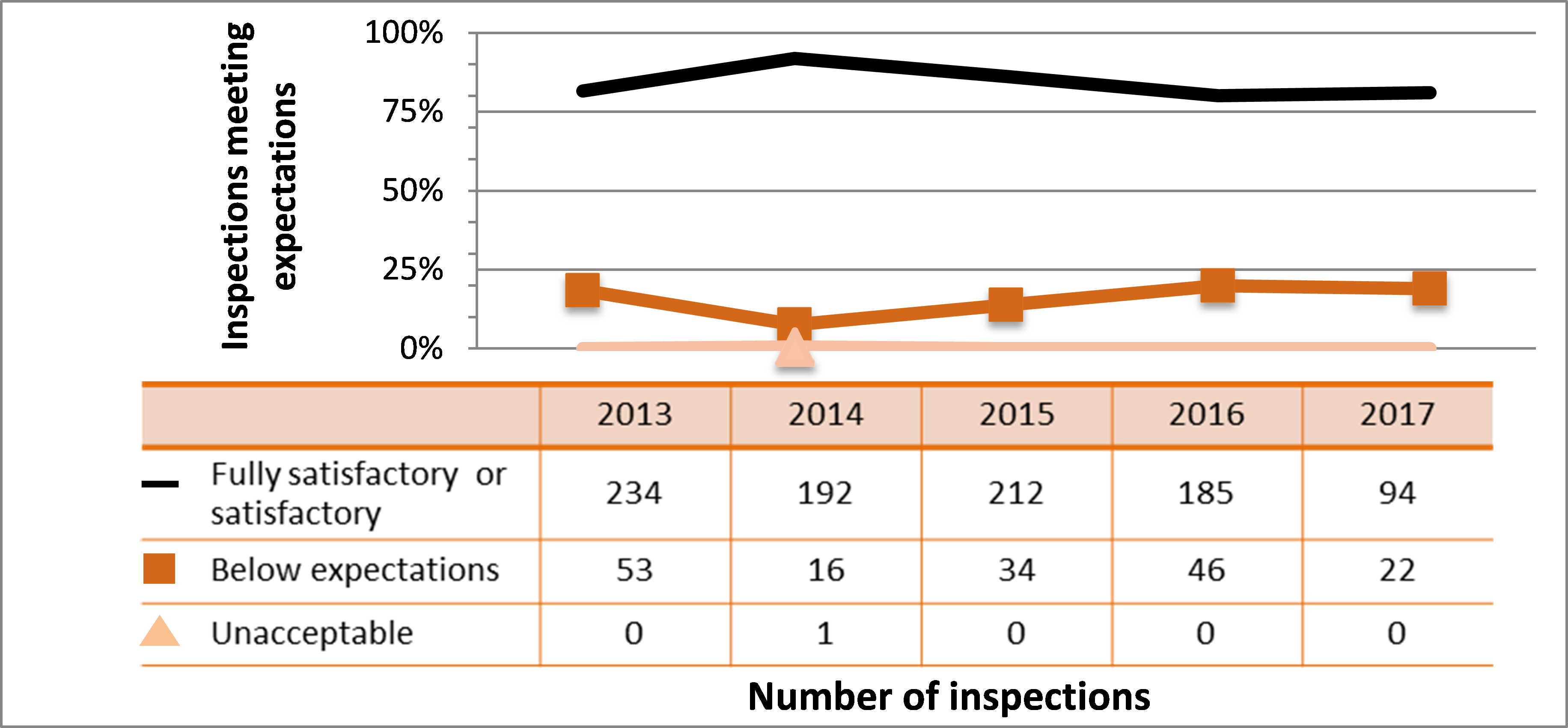

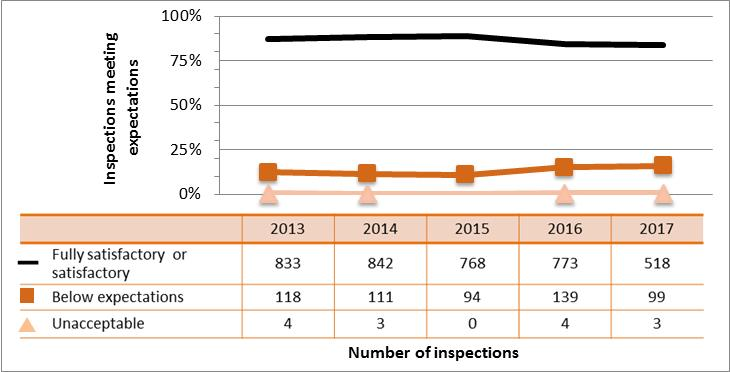

Figure 9: Inspection ratings for radiation protection, 2013–17

Description

| Rating | 2013 | 2014 | 2015 | 2016 | 2017 |

|---|---|---|---|---|---|

| Fully satisfactory or satisfactory | 1,357 | 1,278 | 1,159 | 1,112 | 744 |

| Below expectations | 200 | 152 | 146 | 199 | 129 |

| Unacceptable | 4 | 4 | 0 | 4 | 3 |

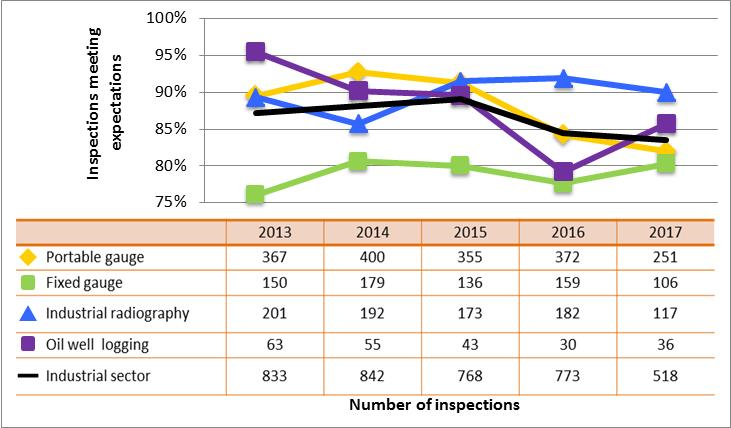

Figure 10: Sector-to-sector comparison of inspection ratings meeting or exceeding expectations for radiation protection, 2013–17

Description

| Sector | 2013 | 2014 | 2015 | 2016 | 2017 |

|---|---|---|---|---|---|

| Medical | 234 | 192 | 212 | 185 | 94 |

| Industrial | 833 | 842 | 768 | 773 | 518 |

| Academic and research | 174 | 117 | 65 | 71 | 69 |

| Commercial | 110 | 118 | 106 | 79 | 59 |

| Waste nuclear substance | 6 | 9 | 8 | 4 | 4 |

| All sectors combined | 1,357 | 1,278 | 1,159 | 1,112 | 744 |

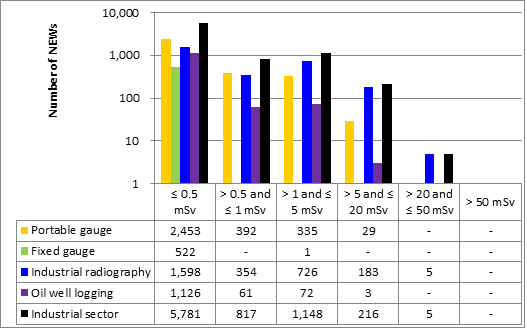

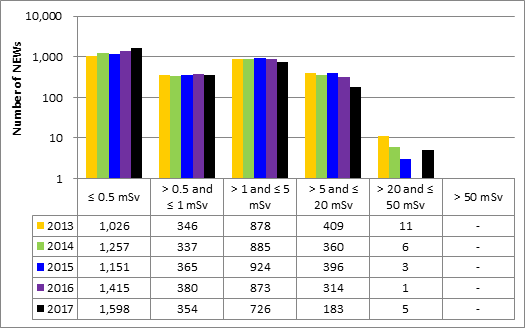

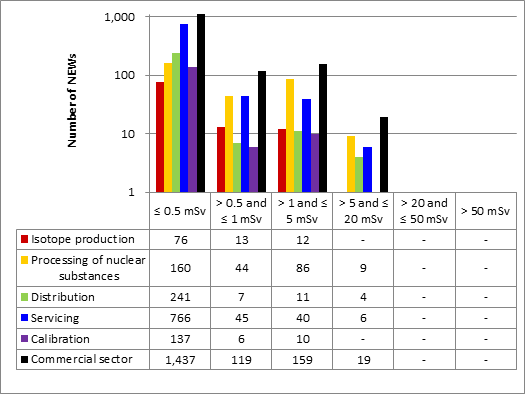

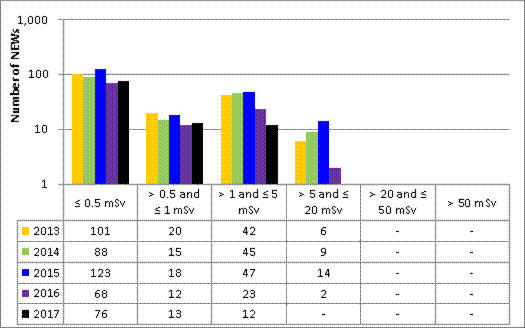

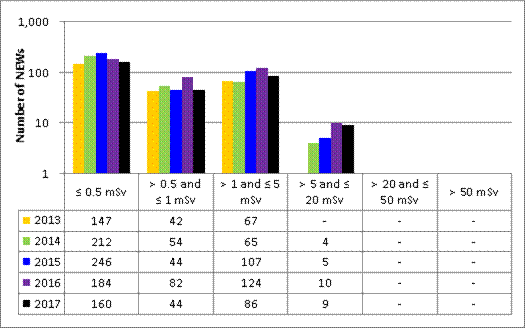

5.5 Security