REGDOC-2.5.2, Design of Reactor Facilities, Version 2

Preface

This regulatory document is part of the CNSC’s physical design series of regulatory documents, which also covers design of uranium mines and mills, design of fixed radiography installations, design of nuclear substance laboratories and nuclear medicine rooms, and exposure devices. The full list of regulatory document series is included at the end of this document and can be found on the CNSC’s website.

REGDOC-2.5.2, Design of Reactor Facilities, sets out requirements and guidance for new licence applications for water-cooled reactor facilities. It establishes a set of comprehensive design requirements and guidance that are risk informed and align with accepted international codes and practices.

This document provides criteria pertaining to the safe design of new water-cooled reactor facilities. All aspects of the design are taken into account, and multiple levels of defence are promoted in design considerations. To the extent practicable, the requirements and guidance provided herein are technology neutral with respect to water-cooled reactor facilities. An applicant or licensee may put forward a case to demonstrate that the intent of a requirement is addressed by other means and demonstrated with supportable evidence.

REGDOC-2.5.2, Design of Reactor Facilities, Version 2, supersedes both REGDOC-2.5.2, Design of Reactor Facilities: Nuclear Power Plants, which was published in May 2014, and RD-367, Design of Small Reactor Facilities, which was published in June 2011.

To a large degree, this regulatory document represents the CNSC’s adoption of the principles set forth by the International Atomic Energy Agency in SSR-2/1, Safety of Nuclear Power Plants: Design, as adapted to align with Canadian requirements.

This regulatory document considers all licensing phases, as information from the design process feeds into the processes for reviewing an application for a licence to construct a water-cooled reactor facility, and other licence applications.

For proposed new facilities: This document will be used to assess new licence applications for reactor facilities.

For existing facilities (In this document, “existing facilities” are effectively those first licensed before 2014.): The requirements contained in this document do not apply unless they have been included, in whole or in part, in the licensing basis.

Guidance contained in this document exists to inform the applicant, to elaborate on requirements, or to provide direction to licensees and applicants on how to meet requirements. It also provides more information about how CNSC staff evaluate specific problems or data during their review of licence applications. Licensees are expected to review and consider this guidance; if they choose not to follow it, they should explain how their selected approach still meets regulatory requirements.

For information on the implementation of regulatory documents and on the graded approach, see REGDOC-3.5.3, Regulatory Fundamentals.

The words “shall” and “must” are used to express requirements to be satisfied by the licensee or licence applicant. “Should” is used to express guidance or that which is advised. “May” is used to express an option or that which is advised or permissible within the limits of this regulatory document. “Can” is used to express possibility or capability.

Nothing contained in this document is to be construed as relieving any licensee from any other pertinent requirements. It is the licensee’s responsibility to identify and comply with all applicable regulations and licence conditions.

Table of contents

- 1. Introduction

- 2. Safety objectives and concepts

- 3. Safety management in design

- 4. Safety requirements

- 5. General design requirements

- 5.1 Safety classification of structures, systems and components

- 5.2 Plant design envelope

- 5.3 Plant states

- 5.4 Postulated initiating events

- 5.5 Design rules and limits

- 5.6 Design for reliability

- 5.7 Pressure-retaining structures, systems and components

- 5.8 Equipment environmental qualification

- 5.9 Instrumentation and control

- 5.10 Safety support system

- 5.11 Guaranteed shutdown state

- 5.12 Fire safety

- 5.13 Seismic qualification and design

- 5.14 In-service testing, maintenance, repair, inspection and monitoring

- 5.15 Civil structure

- 5.16 Construction and commissioning

- 5.17 Aging and wear

- 5.18 Control of foreign material

- 5.19 Transport and packaging for fuel and radioactive waste

- 5.20 Escape routes and means of communication

- 5.21 Human factors

- 5.22 Robustness against malevolent acts

- 5.23 Safeguards

- 5.24 Decommissioning

- 5.25 Provision for extended shutdown

- 5.26 Provision for utilization and modification

- 6. System-specific requirements

- 6.1 Reactor core

- 6.2 Reactor coolant system

- 6.3 Steam supply system

- 6.4 Means of shutdown

- 6.5 Emergency core cooling system

- 6.6 Containment and means of confinement

- 6.6.1 Containment

- 6.6.2 Strength of the containment structure

- 6.6.3 Capability for pressure tests

- 6.6.4 Leakage

- 6.6.5 Containment penetrations

- 6.6.6 Containment isolation

- 6.6.7 Containment airlocks

- 6.6.8 Internal structures of the containment

- 6.6.9 Containment pressure and energy management

- 6.6.10 Control and cleanup of the containment atmosphere

- 6.6.11 Coverings, coatings and materials

- 6.6.12 Design extension conditions

- 6.7 Heat transfer to an ultimate heat sink

- 6.8 Emergency heat removal system

- 6.9 Electrical power systems

- 6.10 Control facilities

- 6.11 Waste treatment and control

- 6.12 Fuel handling and storage

- 6.13 Radiation protection

- 7. Safety analysis

- 8. Environmental protection and mitigation

- 9. Alternative approaches

- Appendix A: Structural Analysis of Containment Structures

- Appendix B: Experimental Devices

- Abbreviations

- Glossary

- References

- Additional Information

1. Introduction

1.1 Purpose

This regulatory document sets out the requirements of the Canadian Nuclear Safety Commission (CNSC) for the design of new water-cooled reactor facilities. It establishes a set of comprehensive design requirements and guidance that are risk-informed and align with accepted national and international codes and practices.

1.2 Scope

This regulatory document deals with a wide variety of topics related to the design of new reactor facilities. To the extent practicable, this document is technology-neutral with respect to water-cooled reactor facilities, and includes requirements and guidance for:

- establishing the safety goals and objectives for the design

- utilizing safety principles in the design

- applying safety management principles

- designing structures, systems and components (SSCs)

- interfacing engineering aspects, plant features and facility layout

- integrating safety assessments into the design process

To a large degree, this document represents the CNSC’s adoption of the principles set forth in the International Atomic Energy Agency (IAEA) document SSR-2/1, Safety of Nuclear Power Plants: Design, and the adaptation of those principles to align with Canadian practices.

It is recognized that specific technologies may use alternative approaches. If a design other than a water-cooled reactor is to be considered for licensing in Canada, the design is subject to the safety objectives, high-level safety concepts and safety management requirements associated with this regulatory document. However, the CNSC will review such designs on a case-by-case basis.

When an applicant proposes to construct more than 1 reactor on a site, the design of the multi-reactor site shall meet the safety objectives in this regulatory document.

Conventional industrial safety is addressed only from a high-level perspective, with a focus on design requirements that are related to nuclear safety.

1.3 Relevant legislation

The following provisions of the Nuclear Safety and Control Act (NSCA) and the regulations under it are relevant to this document:

- NSCA, subsection 24(4) and 24(5)

- General Nuclear Safety and Control Regulations (GNSCR), paragraphs 3(1)(i), 12(1)(f)

- Class I Nuclear Facilities Regulations, paragraphs 3(b), 5(a), (d), (e), (f), (i) (k) and 6(a), (b), (h), (j), (k) and 7(f)

- Other sections of the Class I Nuclear Facilities Regulations, as well as sections of the Radiation Protection Regulations and the Nuclear Security Regulations that pertain to the design of a new reactor facility

2. Safety objectives and concepts

The safety objectives and concepts described in this section apply to a reactor facility during operation or during an accident.

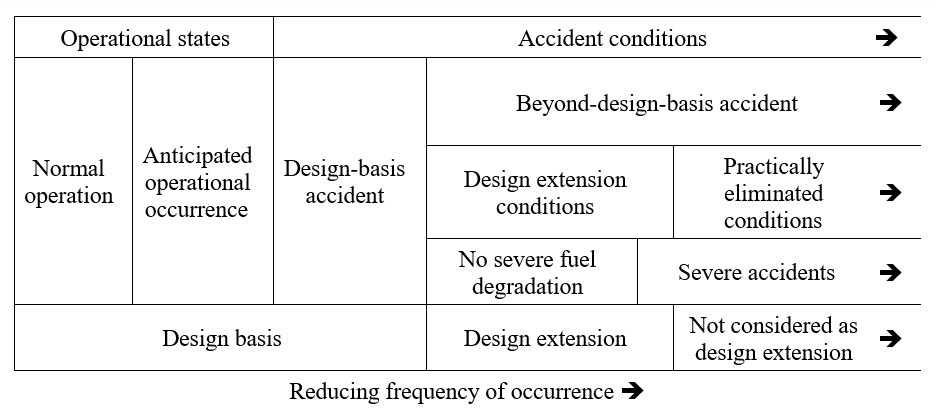

Four common plant states are defined: normal operation, anticipated operational occurrence (AOO), design-basis accident (DBA), and beyond-design-basis accident (BDBA). This document also introduces the plant state “design extension conditions” (DECs), as a subset of BDBAs that are considered in the plant design.

2.1 General nuclear safety objective

In support of the NSCA and its associated regulations, the CNSC endorses the objective established by the IAEA that reactor facilities be designed and operated in a manner that will protect individuals, society and the environment from harm. This objective relies on the establishment and maintenance of effective defences against radiological hazards in reactor facilities.

The general nuclear safety objective is supported by 3 complementary safety objectives, which deal with radiation protection, the technical aspects of the design, and environmental protection. The technical safety objective is interdependent with administrative and procedural measures that are taken to ensure defence against hazards due to ionizing radiation.

2.1.1 Radiation protection objective

The radiation protection objective is to ensure that during normal operation, or during anticipated operational occurrences, radiation exposures within the reactor facility or due to any planned release of radioactive material from the reactor facility are kept below prescribed limits and as low as reasonably achievable (ALARA).

Provisions shall be made for the mitigation of the radiological consequences of any accidents considered in the design.

2.1.2 Technical safety objectives

The technical safety objectives are to provide all reasonably practicable measures to prevent accidents in the reactor facility, and to mitigate the consequences of accidents if they do occur. This takes into account all possible accidents considered in the design, including those of very low probability.

When these objectives are achieved, any radiological consequences will be below prescribed limits, and the likelihood of accidents with serious radiological consequences will be extremely low.

2.1.3 Environmental protection objective

The environmental protection objective is to provide all reasonably practical mitigation measures to protect the environment during the operation of a reactor facility and to mitigate the consequences of an accident.

The design shall include provisions to control, treat and monitor releases to the environment and shall minimize the generation of radioactive and hazardous wastes.

2.2 Application of the technical safety objectives

The NSCA and the technical safety objectives provide the basis for the following criteria and goals:

- dose acceptance criteria

- safety goals

Safety analyses shall be performed to confirm that these criteria and goals are met, to demonstrate effectiveness of measures for preventing accidents and mitigating radiological consequences of accidents if they do occur.

2.2.1 Dose acceptance criteria

The acceptance criteria for normal operations are provided in section 4.4.

The committed whole-body dose for average members of the critical groups who are most at risk, at or beyond the site boundary, shall be calculated in the deterministic safety analysis for a period of 30 days after the analyzed event.

This dose shall be less than or equal to the dose acceptance criteria of:

- 0.5 millisievert (mSv) for any AOO or

- 20 mSv for any DBA

The values adopted for the dose acceptance criteria for AOOs and DBAs are consistent with accepted international practices, and take into account the recommendations of the IAEA and the International Commission on Radiological Protection.

2.2.2 Safety goals

Qualitative safety goals

A limit is placed on the societal risks posed by reactor facility operation. For this purpose, the following 2 qualitative safety goals have been established:

Individual members of the public shall be provided a level of protection from the consequences of reactor facility operation, such that there is no significant additional risk to the life and health of individuals.

Societal risks to life and health from reactor facility operation shall be comparable to or less than the risks of generating electricity by viable competing technologies, and shall not significantly add to other societal risks.

Quantitative application of safety goals

For practical application, the following 3 quantitative safety goals have been established so as to achieve the intent of the qualitative safety goals:

- core damage frequency

- small release frequency

- large release frequency

A core damage accident results from a postulated initiating event (PIE) followed by the failure of 1 or more safety system(s) or safety support system(s). Core damage frequency is a measure of the plant’s accident prevention capabilities.

Small release frequency and large release frequency are measures of the plant’s accident mitigation capabilities. They also represent measures of risk to society and to the environment due to the operation of reactor facilities.

Core damage frequency

The sum of frequencies of all event sequences that can lead to significant core degradation shall be less than 10-5 per reactor year.

Small release frequency

The sum of frequencies of all event sequences that can lead to any release to the environment that requires temporary evacuation of the local population or a release to the environment of more than 1015 becquerels of iodine-131 shall be less than 10-5 per reactor year.

Large release frequency

The sum of frequencies of all event sequences that can lead to any release to the environment that requires long-term relocation of the population or a release to the environment of more than 1014 becquerels of cesium-137 shall be less than 10-6 per reactor year.

Guidance

A comprehensive probabilistic safety assessment (PSA) considers the probability, progression and consequences of equipment failures or transient conditions, to derive numerical estimates for the safety of the plant. Core damage frequency is determined by a Level 1 PSA, which identifies and quantifies the sequence of events that may lead to significant core degradation. The small release frequency and large release frequency are determined by a Level 2 PSA, which starts from the results of a Level 1 PSA, analyzes the containment behaviour, evaluates the radionuclides released from the failed fuel, and quantifies the releases to the environment. An exemption from performing a Level 2 PSA is granted if it is shown that core damage frequency in the Level 1 PSA is sufficiently low (i.e., less than the large release frequency limit).

Calculations of the safety goals include all internal and external events as per REGDOC-2.4.2, Probabilistic Safety Assessment (PSA) for Nuclear Power Plants Footnote 1. However, aggregation of internal events and other hazard risk metrics performed through simple addition to demonstrate that the risk metrics (core damage frequency, small release frequency and large release frequency) are not exceeded might not be appropriate. It is recognized that when the risk metrics for external events are conservatively estimated, their summation with the risk metrics for internal events can lead to misinterpretation. Should the aggregated total exceed the safety goals, conclusions should not be derived from the aggregated total until the scope of the conservative bias in the other hazards is investigated.

Further details on PSAs are contained in section 7.5 of this document and REGDOC-2.4.2.

2.2.3 Safety analyses

To demonstrate achievement of the safety objectives, a comprehensive hazard analysis, a deterministic safety analysis, and a probabilistic safety assessment shall be carried out. These analyses shall identify all sources of exposure in order to evaluate potential radiation doses to workers at the plant and to the public, and to evaluate potential effects on the environment.

The safety analyses shall examine plant performance for:

- normal operation

- AOOs

- DBAs

- BDBAs, including DECs (DECs could include severe accident conditions)

Based on these analyses, the capability of the design to withstand PIEs and accidents shall be confirmed, the effectiveness of the items important to safety demonstrated, and requirements for emergency response established. The results of the safety analyses shall be fed back into the design.

The safety analyses are discussed in further detail in section 7.0.

2.2.4 Accident mitigation and management

The design shall include provisions to limit radiation exposure in normal operation and AOOs to ALARA levels, and to minimize the likelihood of an accident that could lead to the loss of normal control of the source of radiation. However, given that there is a remaining probability that an accident may occur, measures shall be taken to mitigate the radiological consequences of accidents.

These measures shall include:

- consideration of inherent safety features

- incorporation of engineered design features

- onsite accident management procedures established by the operating organization

- establishment of offsite intervention measures by responsible authorities

The design shall apply the principle that plant states that could result in high radiation doses or radioactive releases have a very low frequency of occurrence, and that plant states with significant frequency of occurrence have only minimal – if any – potential radiological consequences.

The design shall facilitate the clear transfer of control between procedures for operational states, accident conditions, severe accident management and onsite emergency response.

Additional information

Additional information may be found in:

- CNSC, REGDOC-2.7.1, Radiation Protection Footnote 2

- CNSC, REGDOC-2.3.2, Accident Management: Severe Accident Management Programs for Nuclear Reactors Footnote 3

- International Atomic Energy Association (IAEA), Specific Safety Guide NS-SG-2.154, Severe Accident Management Programmes for Nuclear Power Plants Footnote 4

2.3 Safety concepts

2.3.1 Defence in depth

The concept of defence in depth shall be applied to all organizational, behavioural, and design-related safety and security activities to ensure that they are subject to overlapping provisions. The levels of defence in depth shall be independent to the extent practicable.

If a failure were to occur, the defence-in-depth approach allows the failure to be detected, and to be compensated for or corrected.

This concept shall be applied throughout the design process and operation of the plant to provide a series of levels of defence aimed at preventing accidents and ensuring appropriate protection in the event that prevention fails.

The design shall provide all of the following 5 levels of defence during normal operation; however, some relaxations may be specified for certain shutdown states. These levels are introduced in general terms below, and are discussed in greater detail in section 6.1.

Level 1

The aim of the first level of defence is to prevent deviations from normal operation, and to prevent failures of SSCs important to safety.

Level 2

The aim of the second level of defence is to detect and intercept deviations from normal operation in order to prevent AOOs from escalating to accident conditions and to return the plant to a state of normal operation.

Level 3

The aim of the third level of defence is to minimize the consequences of accidents by providing inherent safety features, fail-safe design, additional equipment and mitigating procedures.

Level 4

The aim of the fourth level of defence is to ensure that radioactive releases caused by severe accidents are kept as low as practicable.

Level 4

The aim of the fifth level of defence is to mitigate the radiological consequences of potential releases of radioactive materials that may result from accident conditions.

Section 6.1 discusses the application of levels of defence in further detail.

Additional information

Additional information may be found in:

- IAEA, INSAG-10, Defence in Depth in Nuclear Safety Footnote 5

2.3.2 Physical barriers

An important aspect of implementing defence in depth in the reactor facility design shall be the provision of a series of physical barriers to confine radioactive material at specified locations. Physical barriers are discussed in further detail in section 6.1.1.

2.3.3 Operational limits and conditions

Operational limits and conditions (OLCs) are the set of limits and conditions that can be monitored by or on behalf of the operator and that can be controlled by the operator.

OLCs shall be established to ensure that plants operate in accordance with design assumptions and intent (parameters and components), and include the limits within which the facility has been shown to be safe. OLCs shall be documented in a manner that is readily accessible for control room personnel, with the roles and responsibilities clearly identified. Some OLCs may include combinations of automatic functions and actions by personnel.

OLCs shall include:

- safety limits

- limiting safety system settings

- OLCs for normal operation and AOOs, including shutdown states

- control system constraints and procedural constraints on process variables and other important parameters

- requirements for surveillance, maintenance, testing and inspection of the plant to ensure that SSCs function as intended in the design and comply with the requirement for optimization by keeping radiation exposures ALARA, as per the Radiation Protection Regulations

- specified operating configurations, including operational restrictions in the event of the unavailability of SSCs important to safety

- action statements, including completion times for actions in response to deviations from the operational limits and conditions

The basis on which the OLCs are derived shall be readily available in order to facilitate the ability of plant personnel to interpret, observe and apply the OLCs.

Guidance

The approaches and terminologies used for OLCs may vary as a result of the practices and regulatory systems that have been established in the country of origin for the plant’s design.

Regardless of the approaches and terminologies used, the design authority should provide clear definitions of OLC terminology. The design should also include clear objectives and goals for the OLCs.

The information related to OLCs should list the relevant standards (national or international) used, and document how the requirements from these standards have been met.

OLCs should be defined for a suitable set of bounding plant operating configurations, and be based on the final design of the plant.

Additional information

Additional information may be found in:

- CSA Group, N290.15, Requirements for the safe operating envelope of nuclear power plants Footnote 6

- IAEA Safety Guide NS-G-2.2, Operational Limits and Conditions and Operating Procedures for Nuclear Power Plants Footnote 7.

2.3.4 Interface of safety with security and safeguards

Safety measures, nuclear security measures and arrangements for the system of accounting for, and control of, nuclear material for a reactor facility shall be designed and implemented in an integrated manner so that they do not compromise one another.

2.4 Graded approach

For information and guidance on the implementation and use of the graded approach, refer to REGDOC-3.5.3, Regulatory Fundamentals Footnote 8.

2.4.1 Application of the graded approach

When a graded approach is applied, factors to be considered could include, but are not limited to:

- reactor power

- reactor safety characteristics

- amount and enrichment of fissile and fissionable material

- fuel design

- type and mass of moderator, reflector and coolant

- utilization of the reactor

- presence of high energy sources and other radioactive and hazardous sources

- safety design features

- source term

- siting

- proximity to populated areas

3. Safety management in design

The applicant or licensee shall be ultimately responsible for the design of the reactor facility and shall establish a management system for ensuring the continuing safety of the plant design throughout the lifetime of the reactor facility.

The reactor facility design shall:

- meet Canadian regulatory requirements

- meet the design specifications

- be confirmed by safety assessment

- take into account current safety practices

- fulfill the requirements of an effective management system

- incorporate only those design changes that have been justified by technical and safety assessments

The design process shall be carried out by technically qualified and appropriately trained staff at all levels, and shall include:

- a clear division of responsibilities with corresponding lines of authority and communication

- clear interfaces between the groups engaged in different parts of the design, and between designers, utilities, suppliers, builders and contractors, as appropriate

- design control measures (such as processes, procedures, and practices) as part of an established management system

- a management system that recognizes the importance of a healthy safety culture

3.1 Design authority

During the design phase, formal design authority typically rests with the organization that has overall responsibility for the design. Prior to plant start-up, this authority shall be transferred to the operating organization.

The design authority may assign responsibility for the design of specific parts of the plant to other organizations, known as responsible designers. The tasks and functions of the design authority and any responsible designer shall be established in formal documentation; however, the overall responsibility remains with the design authority.

The applicant or licensee shall confirm that the design authority has achieved the following objectives for the design:

- established a knowledge base of all relevant aspects of the plant design and kept it up to date, while taking experience and research findings into account

- ensured the availability of the design information that is needed for safe plant operation and maintenance

- established the requisite security provisions in accordance with the Nuclear Security Regulations and associated regulatory documents

- maintained design configuration control

- reviewed, verified, approved and documented design changes

- established and controlled the necessary interfaces with responsible designers or other suppliers engaged in design work

- ensured that the necessary engineering and scientific skills and knowledge have been maintained

- ensured that, with respect to individual design changes or multiple changes that may have significant interdependencies, the associated impact on safety has been properly assessed and understood.

Additional information

Note: CSA N286.7, Quality Assurance of Analytical, Scientific, and Design Computer Programs for Nuclear Power Plants, and N286.7.1, Guideline for the application of N286.7-99, Quality assurance of analytical, scientific, and design computer programs for nuclear power plants Footnote 14, have been merged.

Additional information may be found in:

- CSA Group, N286, Management system requirements for nuclear power plants Footnote 9

- IAEA, Safety Standards Series GS-G-3.5, The Management System for Nuclear Installations Safety Guide Footnote 10

- IAEA, INSAG-19, Maintaining the Design Integrity of Nuclear Installations throughout their Operating Life Footnote 11

3.2 Design management

Appropriate design management shall achieve the following objectives:

- SSCs important to safety meet their respective design requirements.

- Due account is taken of the human capabilities and limitations of personnel.

- Safety design information - necessary for safe operation and maintenance of the plant and for any subsequent plant modifications - is preserved.

- OLCs are provided for incorporation into the plant administrative and operational procedures.

- The plant design facilitates maintenance and aging management throughout the life of the plant.

- The results of the hazard analysis, deterministic safety analysis and probabilistic safety assessment are taken into account.

- Due consideration is given to the prevention of accidents and mitigation of their consequences.

- The generation of radioactive and hazardous waste is limited to minimum practicable levels, in terms of both activity and volume.

- A change control process is established to track design changes in order to provide configuration management during manufacturing, construction, commissioning and operation.

- Physical protection systems and cyber security programs are provided to address design-basis threats.

3.3 Design control measures

Processes, procedures and practices shall be established as part of the overall management system so as to achieve the design objectives. This shall include identifying all performance and assessment parameters for the plant design, as well as detailed plans for each SSC, in order to ensure consistent quality of the design and the selected components.

The design controls shall be such that the initial design, and any subsequent change or safety improvement, is carried out in accordance with established processes and procedures, which call on appropriate standards and codes and address applicable requirements and design bases.

Appropriate design control measures shall also facilitate identification and control of design interfaces.

The adequacy of the design, including design tools and design inputs and outputs, shall be verified or validated by individuals or groups that are independent from those who originally performed the work. Verifications, validations, and approvals shall be completed before the detailed design is implemented.

The computer software used for design and analysis calculations shall be qualified in accordance with applicable standards.

Guidance

Design control measures, in the form of processes, procedures and practices, include:

- design initiation, including identification of scope

- work control and planning of design activities

- selection of competent staff

- identification and control of design inputs

- establishment of design requirements

- evaluation of design concepts and selection of preferred concept

- selection of design tools and computer software

- conduct of conceptual safety analysis to assess preferred design concept

- conduct of detailed design and production of design documentation and records

- definition of any limiting conditions for safe operation

- design verification and validation

- configuration management

- identification and control of design interfaces

CSA N286, Management system requirements for nuclear facilities Footnote 9, is the Canadian standard identifying management system requirements for the design, purchasing, construction, installation, commissioning, operating, and decommissioning of reactor facilities. CSA N286.7, Quality assurance of analytical, scientific, and design computer programs Footnote 13, and CSA N286.7, Quality Assurance of Analytical, Scientific and Design Computer Programs for Nuclear Power Plants Footnote 14, provide complementary requirements and guidance for analytical, scientific and design computer programs.

Organizations from nations not using the aforementioned documents should identify the codes, standards, and specifications on which their design and safety analysis control measures are based, whether national or international – such as IAEA GS-G-3.5, The Management System for Nuclear Installations Safety Guide, referenced publications, and ISO 9001:2008 Quality Management Systems – Requirements Footnote 10. Such control measures should be mapped to the requisite CSA N286 clauses to demonstrate that they satisfy Canadian requirements. Where gaps are identified, the measures to address them should be described.

Organizational processes and procedures can be specific to design and safety analysis, or be part of an overall management system (or quality assurance program) for other reactor facility lifecycle activities. In the latter case, the organization should identify those processes and procedures applicable to design and safety analysis.

There are no specific platforms, styles or format requirements for documenting design control measures; however, design organizations should identify the types of documents, the style, the format and the media (paper-based, electronic or Web-based) they intend to use to control their design activities.

Additional information

Additional information may be found in:

- American Society of Mechanical Engineers (ASME), NQA-1-2008, Quality Assurance Requirements for Nuclear Facility Applications Footnote 12

- CSA N286.7, 3rd Edition, 2021 – Quality assurance of analytical, scientific, and design computer programs Footnote 13

- CSA Group, N286, Management system requirements for nuclear power plants Footnote 9

- CSA Group, N286.7.1, Guideline for the application of N286.7-99, Quality assurance of analytical, scientific, and design computer programs for nuclear power plants Footnote 14

- IAEA, GS-R-3, The Management System for Facilities and Activities Footnote 15

- Nuclear Information and Records Management Association/American National Standards Institute (ANSI), 1.0, Standard Configuration Management, Washington, D.C., 2007 Footnote 16

3.4 Proven engineering practices

The design authority shall identify the modern codes and standards that will be used for the plant design, and evaluate those codes and standards for applicability, adequacy, and sufficiency to the design of SSCs important to safety.

Where needed, codes and standards shall be supplemented to ensure that the final quality of the design is commensurate with the necessary safety functions.

SSCs important to safety shall be of proven design, and shall be designed according to the standards and codes identified for the reactor facility.

When a new SSC design, feature or engineering practice is introduced, adequate safety shall be demonstrated by a combination of supporting research and development programs and by examination of relevant experience from similar applications. An adequate qualification program shall be established to verify that the new design meets all applicable safety requirements. New designs shall be tested before being brought into service and shall be monitored while in service so as to verify that the expected behaviour is achieved.

The design authority shall establish an adequate qualification program to verify that the new design meets all applicable design safety requirements.

In the selection of equipment, due attention shall be given to spurious operation and to unsafe failure modes (e.g., failure to trip when necessary). Where the design has to accommodate an SSC failure, preference shall be given to equipment that exhibits known and predictable modes of failure, and that facilitates repair or replacement.

3.5 Operational experience and safety research

The reactor facility design shall draw on operational experience that has been gained in the nuclear industry, and on the results of relevant research programs.

Guidance

The design authority should describe the major design features, changes and improvements that have been incorporated as a result of operational experience and safety research, including:

- resolution of applicable safety issues from existing reactor designs

- improvements in design due to advances in materials and their properties

- improved methods of design and safety assessment

- improved methods of construction and fabrication

- improvements in reliability, operability and maintainability

- improved methods to mitigate the occurrence and consequences of human error

- improved methods in support of ALARA

Operational experience can be found in documents such as the IAEA yearly publication Operating Experience with Nuclear Power Stations in Member States.

Additional information

Additional information may be found in:

- IAEA Safety Guide Series NS-G-2.11, A System for the Feedback of Experience from Events in Nuclear Installations Footnote 17

3.6 Safety assessment

Safety assessment is a systematic process applied throughout the design phase to ensure that the design meets all relevant safety requirements. The safety assessment for the design shall include the requirements set by the operating organization and by regulatory authorities. The basis for the safety assessment shall be the data derived from the safety analysis, previous operational experience, results of supporting research, and proven engineering practices.

The safety assessment shall be part of the design process, with iteration between the design and analyses, and shall increase in scope and level of detail as the design process progresses.

Before the design is submitted, an independent peer review of the safety assessment shall be conducted by individuals or groups separate from those carrying out the design.

Safety assessment documentation shall identify those aspects of operation, maintenance and management that are important to safety. This documentation shall be maintained in a dynamic suite of documents, to reflect changes in design as the plant evolves.

Safety assessment documentation shall be presented clearly and concisely, in a logical and understandable format, and shall be made readily accessible to designers, operators and the CNSC.

Guidance

As per IAEA GSR Part 4, Safety Assessment for Facilities and Activities Footnote 18, aspects considered in the safety assessment should include:

- defence in depth

- safety margins

- multiple barriers

- safety analysis (including both deterministic and probabilistic approaches), as well as overall scope, approach, safety criteria, uncertainty and sensitivity analysis, use of computer codes, and use of operating experience

- radiation risks

- safety functions

- site characteristics

- radiation protection

- engineering aspects

- human factors

- long-term safety

The independent peer review should be performed by suitably qualified and experienced individuals.

Additional information

Additional information may be found in:

- IAEA, GSR Part 4, Safety Assessment for Facilities and Activities Footnote 18.

3.7 Design documentation

Design documentation shall include information to demonstrate the adequacy of the design and shall be used for procurement, construction, commissioning and safe operation, including maintenance, aging management, modification and eventual decommissioning of the reactor facility.

The design documentation shall include:

- design description

- design requirements

- classification of SSCs

- description of plant states

- security system design, including a description of physical security barriers and cyber security programs

- operational limits and conditions

- identification and categorization of initiating events

- acceptance criteria and derived acceptance criteria

- deterministic safety analysis

- probabilistic safety assessment (PSA)

- hazard analysis

Guidance

A suite of design documentation should be developed, following the establishment of an overall baseline, listing all key design documents. Design documents should be contained in a logical and manageable framework.

For additional guidance on derived acceptance criteria, refer to REGDOC-2.4.1, Deterministic Safety Analysis Footnote 20.

Additional information

Additional information may be found in:

- REGDOC-1.1.2, Licence Application Guide: Licence to Construct a Nuclear Power Plant Footnote 19.

- CNSC, REGDOC-2.4.1, Deterministic Safety Analysis Footnote 20

4. Safety requirements

4.1 Application of defence in depth

The design of a reactor facility shall incorporate defence in depth. The levels of defence in depth shall be independent to the extent practicable.

Defence in depth shall be achieved at the design phase through the application of design provisions specific to the 5 levels of defence.

Level 1

Achievement of Level 1 defence in depth shall include conservative design and high-quality construction to provide confidence that plant failures and deviations from normal operations are minimized and accidents are prevented.

This shall entail careful attention to selection of appropriate design codes and materials, design procedures, equipment qualification, control of component fabrication and plant construction, and use of operational experience.

Level 2

Level 2 shall be achieved by controlling plant behaviour during and following a postulated initiating event (PIE) using both inherent and engineered design features to minimize or exclude uncontrolled transients to the extent possible.

Level 3

Achievement of Level 3 defence in depth shall include the provision of inherent safety features, fail-safe design, engineered design features, and procedures that minimize the consequences of DBAs. These provisions shall be capable of leading the plant first to a controlled state, and then to a safe shutdown state, and maintaining at least 1 barrier for the confinement of radioactive material. Automatic activation of the engineered design features shall minimize the need for operator actions in the early phase of a DBA.

Level 4

Level 4 shall be achieved by providing equipment and procedures to manage accidents and mitigate their consequences as far as practicable.

Most importantly, adequate protection shall be provided for the confinement function by way of a robust containment design. This includes the use of complementary design features to prevent accident progression and to mitigate the consequences of DECs. The confinement function shall be further protected by severe accident management procedures.

Level 5

The design shall provide adequately equipped emergency support facilities, and plans for onsite and offsite emergency response.

Guidance

IAEA INSAG-10, Defence in Depth in Nuclear Safety, provides information regarding the concept and application of defence in depth Footnote 5.

Guidance on performing a systematic assessment of the defence in depth can be obtained from the IAEA safety reports series No. 46, Assessment of Defence in Depth for Nuclear Power Plants.

The application of defence in depth in the design should ensure the following:

- The approach to defence in depth used in the design should ensure that all aspects of design at the SSCs level have been covered, with emphasis on SSCs that are important to safety.

- The defence in depth should not be significantly degraded if the SSC has multiple functions (e.g., for CANDU reactors, the moderator and end-shield cooling systems may serve the functions of a process system and include the functions of mitigating DECs).

- The principle of multiple physical barriers to the release of radioactive material should be incorporated in the design; there should be a limited number of cases where there is a reduction in the number of physical barriers (as may be the case where some components carrying radioactive material serve the function of primary coolant barrier and containment), and adequate justification should exist for such design choices.

- The design (e.g., in safety design guides, management system programs) should provide:

- levels of defence in depth that are addressed by individual SSCs

- supporting analysis and calculation

- evaluation of operating procedures

- The safety analysis should demonstrate that the challenges to the physical barriers do not exceed their physical capacity.

- The structure for defence in depth provisions at each level of defence should be established for a given plant design, and the evaluation of the design from the point of view of maintaining each safety function should be carried out. This evaluation should consider each and every one of the provisions for mitigation of a given challenge mechanism, and confirm that it is well founded, sufficient, feasible, and correctly engineered within the design.

- Special attention should be paid to the feasibility of a given provision and the existence of supporting safety analyses. Deficiencies in the completeness of the supporting safety analyses should be documented and flagged as issues to be queried.

To ensure that different levels of defence are independently effective, any design features that aim to prevent an accident should not belong to the same level of defence as design features that aim to mitigate the consequences of the accident.

The independence between all levels of defence should be achieved, in particular, through diverse provisions. The strengthening of each of these levels separately would provide, as far as reasonably achievable, an overall reinforcement of defence in depth. For example, the use of dedicated systems to deal with DECs ensures the independence of the fourth defence level.

4.1.1 Physical barriers

To ensure that the overall safety concept of defence in depth is maintained, the design shall provide multiple physical barriers to the uncontrolled release of radioactive materials to the environment. Such barriers shall include the fuel matrix, the fuel cladding, the reactor coolant pressure boundary, and the containment. In addition, the design shall provide for an exclusion zone.

To the extent practicable, the design shall prevent:

- challenges to the integrity of physical barriers

- failure of a barrier when challenged

- failure of a barrier as a consequence of failure of another barrier

- the possibility of failure of engineered barriers from errors in operation and maintenance that could result in harmful consequences

The design shall also allow for the fact that the existence of multiple levels of defence does not normally represent a sufficient basis for continued power operation in the absence of 1 defence level.

4.2 Safety functions

The reactor facility design shall provide adequate means to:

- maintain the plant in a normal operational state

- ensure the proper short-term response immediately following a PIE

- facilitate the management of the plant in and following DBAs and DECs

The following fundamental safety functions shall be available in operational states, DBAs and DECs, except where the postulated accident involves a loss of that function:

- control of reactivity

- removal of heat from the fuel

- confinement of radioactive material

- shielding against radiation

- control of operational discharges and hazardous substances, as well as limitation of accidental releases

- monitoring of safety-critical parameters to guide operator actions

These safety functions shall apply to the reactor as well as fuel storage and handling.

SSCs necessary to fulfill safety functions following a PIE shall be identified. This approach shall identify the need for such functions as reactor shutdown, emergency core cooling, containment, emergency heat removal and power systems.

4.3 Accident prevention and plant safety characteristics

The design shall apply the principles of defence in depth to minimize sensitivity to PIEs. Following a PIE, the plant is rendered safe by:

- inherent safety features

- passive safety features

- specified procedural actions

- action of control systems

- action of safety systems

- action of complementary design features

4.4 Radiation protection and acceptance criteria

Achievement of the general nuclear safety objective (discussed in section 4.1) depends on all actual and potential sources of radiation being identified, and on provision being made to ensure that sources are kept under strict technical and administrative control.

Radiation doses to the public and to site personnel shall be as low as reasonably achievable. During normal operation, including maintenance and decommissioning, doses shall be regulated by the limits prescribed in the Radiation Protection Regulations.

The design shall include provisions for the prevention and mitigation of radiation exposures resulting from DBAs and DECs.

The design shall also ensure that potential radiation doses to the public from AOOs and DBAs do not exceed dose acceptance criteria provided in section 2.2.1. The calculated overall risk to the public shall meet the safety goals in section 2.2.2.

Guidance

A detailed radiation dose assessment should include estimated annual collective and individual effective and equivalent radiation doses to site personnel and members of the public for normal operation, potential radiation doses to the public for AOOs and DBAs, and potential releases into the environment for DECs.

The assessment process should be clearly documented and should include the process for consideration and evaluation of dose-reduction changes in the reactor facility design. Radiation doses resulting from the operation of the reactor facility should be reduced by means of engineered controls and radiation protection measures to levels such that any further expenditure on design, construction and operational measures would not be warranted by the expected reduction in radiation doses.

The radiation dose assessment should include the expected occupancy of the reactor facility’s radiation areas, along with estimated annual person-Sievert doses associated with major functions, including radioactive waste handling, normal maintenance, special maintenance, refuelling and in-service inspection. Such assessments should include information as to how ALARA and operating experience are used in the design to deal with dose-significant contributors.

Additional information

Additional information may be found in:

- CNSC, REGDOC-2.7.1, Radiation Protection Footnote 2

- CSA Group, N288.2, Guidelines for calculating the radiological consequences to the public of a release of airborne radioactive material for nuclear reactor accidents, Toronto, Canada.

4.5 Exclusion zone

The design shall include adequate provision for an appropriate exclusion zone. The appropriateness of the exclusion zone shall be based on several factors, including:

- evacuation needs

- land usage needs

- security requirements

- environmental factors

Guidance

The exclusion zone for reactor facilities in Canada has been typically defined as 914 metres from the reactor building. Rather than prescribe a particular size for the exclusion zone, this regulatory document specifies factors that must be considered in establishing an appropriate size, including evacuation needs, land usage needs, security requirements and environmental factors.

Evacuation needs

The design should take into account emergency response requirements based on the size of the exclusion zone and the facilities and infrastructures that are within the zone.

The exclusion zone boundary should be defined with consideration for the capabilities of onsite and offsite emergency response. Environmental factors that can affect the response times should be taken into consideration. The design also considers projected changes over time in land use and population density, which could adversely affect response times, or the ability to shelter or evacuate persons from both the site itself and associated emergency planning regions.

Evacuation needs are generally based on existing provincial nuclear emergency response plans.

Land usage needs

The design should ensure that the exclusion zone is large enough to accommodate the site for the nuclear plant (accounting for the full number of units postulated to be built at the site, whether or not they would be built immediately).

The design activities should seek to optimize land usage by the plant as part of determining the exclusion zone.

Security requirements

The design should provide security requirements based on the size of the exclusion zone, the facilities and infrastructures that are within the zone, and the design of the facility. Generally, a larger exclusion zone would require more security capabilities, in order to avoid a longer response time. Physical characteristics of the site itself (which include geographical characteristics, such as proximity to elevated land) also play a role in determining these requirements.

The design authority may decide to mitigate these risks while maintaining a smaller exclusion zone by choosing highly robust facility designs, applying engineered security measures to the site, and having a well-designed security program. These engineered measures should be described.

In establishing the radius of the exclusion zone boundary, the design should take into account:

- the site selection and threat assessment report

- facility robustness against natural and human induced external hazards (including malevolent acts)

- the capability of the onsite security program, along with any offsite security resources that will supplement the onsite security program

In each of the above parameters, the design should take into account projected changes over time in land use and population density, which could adversely affect that parameter. The design should be such that the exclusion zone, as established at the design stage, will be sustainable for the full lifecycle of the facility.

The acceptability of the information to be provided in support of the above is discussed in section 7.22 of this document.

Environmental factors

Environmental factors that may have an impact on the size of the exclusion zone include local meteorological conditions that could affect the radiological dose received by members of the public. The design authority may use generic site data and conservative assumptions regarding meteorological conditions in the absence of a specific site.

The Radiation Protection Regulations establish an effective dose limit of 1 mSv per year for members of the public. This limit implies that a hypothetical member of the public who lives at the exclusion zone boundary for 1 year (since no permanent dwelling is permitted within the exclusion zone) would not accumulate a dose of more than 1 mSv from normal operation of the reactor facility.

Additional information

Additional information may be found in:

- CNSC, REGDOC-1.1.1, Site Evaluation and Site Preparation for New Reactor Facilities Footnote 22

4.6 Reactor facility layout

The reactor facility layout shall take into account PIEs to enhance protection of SSCs important to safety.

The design shall take into account the interfaces between the safety, security and safeguard provisions of the reactor facility and other aspects of the facility layout, such as:

- access routes for normal operational actions and maintenance

- access control to minimize radiation exposures

- actions taken in response to internal or external events

- egress routes

- movement of hazardous substances, nuclear materials, and radioactive materials

- movement of authorized and unauthorized personnel

- interaction of building and support functions

It is likely that some design requirements associated with these factors will conflict with others in the determination of facility layout requirements. The design, therefore, shall reflect an assessment of options, demonstrating that an optimized configuration has been sought for the facility layout.

4.6.1 Requirements for multiple units

The design shall take due account of challenges to multiple units at a site. Specifically, the risk associated with common-cause events affecting more than 1 unit at a time shall be considered.

Guidance

The presence of multiple units at a site or common-cause events could exacerbate challenges that the plant personnel would face during an accident. The events and consequences of an accident at 1 unit may affect the accident progression or hamper accident management activities at the neighbouring unit; available resources (personnel, equipment and consumable resources) would need to be shared among several units. These challenges should be identified and the available resources and mitigation strategies shown to be adequate.

5. General design requirements

5.1 Safety classification of structures, systems and components

The design authority shall classify SSCs using a consistent and clearly defined classification method. The SSCs shall then be designed, constructed, and maintained such that their quality and reliability is commensurate with this classification.

In addition, all SSCs shall be identified as either important or not important to safety. The criteria for determining safety importance is based on:

- safety function(s) to be performed

- consequence(s) of failure

- probability that the SSC will be called upon to perform the safety function

- the time following a PIE at which the SSC will be called upon to operate, and the expected duration of that operation

SSCs important to safety shall include:

- safety systems

- complementary design features

- safety support systems

- other SSCs whose failure may lead to safety concerns (e.g., process and control systems)

Appropriately designed interfaces shall be provided between SSCs of different classes in order to minimize the risk of having SSCs less important to safety adversely affect the function or reliability of SSCs of greater importance.

Guidance

The method for classifying the safety significance of SSCs should be based primarily on deterministic methodologies, complemented (where appropriate) by probabilistic methods and engineering judgment. The safety classification of SSCs should be an iterative process that continues throughout the design process.

The SSC classification process should include the following activities:

- review and definition of PIEs

- grouping and identification of bounding PIEs

- identification of plant-specific safety functions to prevent or mitigate the PIEs

- safety categorization of the safety functions, in accordance with their safety significance and role in achieving fundamental safety functions

- identification of SSCs that provide the safety functions

- assignment of SSCs to a safety class corresponding to the safety category

- verification of SSC classification

- identification of engineering design rules for classified SSCs

This approach should be used for all SSCs including pressure retaining components, electrical, instrumentation and control (I&C) and civil structures.

The identified PIEs should be grouped into limiting cases, which are referred to as bounding or enveloping PIEs. Once these bounding PIEs are known and understood, the required safety functions can be identified. The number of categories and classes may be chosen to allow for graded design rules.

The time following the PIE captures the need for automatic action for short timescales, or manual actions being acceptable for longer-term actions. The expected duration of the operation is also important since some systems may need to operate for months. Others (such as shutdown means) can complete their mission within seconds.

The potential severity of the consequences of a function failure should be evaluated. The severity should be based on the consequences that could arise if the function was not performed. The consequences of a function failure should be determined assuming that the safety functions belonging to the subsequent level of defence in depth remain functional.

Some specific SSCs classification guidelines are given below:

- SSCs whose failure cannot be accepted because the failure will certainly result in unacceptable consequences should be allocated to the highest safety class.

- Supporting SSCs that are essential to achieve the safety function of the frontline SSCs to be supported should be assigned to the same class as that of the frontline SSCs.

- An SSC that contributes to the performance of several safety functions of different categories should be assigned to the class corresponding to the highest category of those safety functions requiring the commensurate design rules.

- Any SSC that is not part of a safety function group, but whose failure could adversely affect this safety function group in accomplishing its safety function (if this cannot be precluded by design) should be classified in accordance with the safety category of that safety function group.

- Where the safety class of connecting or interacting SSCs is not the same (including cases where 1 SSC belonging to a safety class is connected to another SSC not important to safety), the interference between the SSCs should be separated by a device (e.g., a physical or optical isolator) classified in the higher safety class. This is to ensure that the failure of a lower safety class SSC will not propagate to an SSC belonging to a higher safety class.

The adequacy of the safety classification should be verified using deterministic safety analysis, which should cover all PIEs and all the credited safety functions. This verification should be complemented, as appropriate, by insight from probabilistic safety assessment and by engineering judgment.

The appropriate design rules and limits as indicated in section 7.5 are specified in accordance with the safety class of SSCs.

Although the probability of SSCs being called upon during DECs is very low, the failure of safety functions for the mitigation of DECs may lead to very severe consequences. SSCs that provide these safety functions should be assigned a safety category commensurate with the safety significance. For certain complementary design features (such as onsite portable equipment) with high redundancy and extremely low probability of being called upon, a low safety class may be appropriate. It should be noted that not all portable equipment is included in SSCs important to safety.

Firstly, SSCs are identified as important or not important to safety. By virtue of their roles, safety systems, complementary design features and safety support systems will be identified as important to safety. Additionally, other SSCs that can have a significant impact on nuclear safety will also be identified as important to safety.

After the SSCs important to safety are identified, they are classified. The safety classification considers a number of factors as listed above. The safety classification enables appropriate design rules to be selected as described in section 7.5.

5.2 Plant design envelope

The design authority shall establish the plant design envelope, which comprises all plant states considered in the design: normal operation, AOOs, DBAs and DECs, as shown in figure 1.

Figure 1: Text version

Table showing the different plant states

First row: Operational states and Accident conditions. Below operational states, there is normal operation, anticipated operational occurrence. Under accident condition we find design basis. The normal operation, anticipated operational occurrence and design-basis accident are part of the design basis.

To the right of these three states under accident conditions, there is design extension condition and practically eliminated conditions. Under design extension condition, there is a category with no severe fuel degradation and a small portion in the severe accident range, which is also under practically eliminated conditions. The Design extension condition are under Design extension and some severe accident and practically eliminated conditions are not considered in the design.

Going from left to right is a reducing frequency of occurrence arrow.

The design basis shall specify the capabilities that are necessary for the plant in operational states and DBAs.

Conservative design measures and sound engineering practices shall be applied in the design basis for operational states and DBAs. This will provide a high degree of assurance that no significant damage will occur to the reactor core, and that radiation doses will remain within established limits.

Complementary design features address the performance of the plant in DECs.

Guidance

The design basis for each SSC important to safety should be systematically defined and justified. The design should also provide the necessary information for the operating organization to run the plant safely.

The design should adopt deterministic design principles of appropriate conservatism. For example, SSCs should be robust, tolerant of a large spectrum of faults with a gradual degradation in their effectiveness, and should not fail catastrophically under operational states, DBAs and DECs.

The conditions for deviating from conservative and deterministic design principles should be clearly stated, including the basis by which such deviation would be justified case by case; such a basis may include a more sophisticated calculation methodology that has been well established, or a multiplicity of ways in which a particular function can be fulfilled.

A complementary design feature is a design feature added to the design as a stand-alone SSC (including portable equipment), or added capability to an existing SSC to cope with DECs.

The design principles for complementary design features to deal with DECs do not necessarily need to incorporate the same degree of conservatism as those applied to the design up to and including DBAs. However, the design authority should provide reasonable assurance that the complementary design features will function as designed when called upon.

5.3 Plant states

Plant states considered in the design shall be grouped into the following 4 categories:

- Normal operation is an operation within specified OLCs, including start-up, power operation, shutting down, shutdown, maintenance, testing, and refuelling.

- An anticipated operational occurrence (AOO) is a deviation from normal operation that is expected to occur once or several times during the operating lifetime of the reactor facility but that, in view of the appropriate design provisions, does not cause any significant damage to items important to safety, or lead to accident conditions.

- Design-basis accidents (DBAs) are accident conditions for which a reactor facility is designed according to established design criteria, and for which damage to the fuel and the release of radioactive material are kept within regulated limits.

- Design extension conditions (DECs) are a subset of beyond-design-basis accidents (BDBAs) that are considered in the design process of the facility in accordance with best-estimate methodology to keep releases of radioactive material within acceptable limits. DECs could include severe accidents.

Acceptance criteria shall be assigned to each plant state considered in the design, taking into account the principle that frequent PIEs will have only minor or no radiological consequences, and that any events that may result in severe consequences will be of extremely low probability.

Guidance

Plant states considered in the design are divided into normal operation, AOOs, DBAs and DECs. The design requirements of SSCs should then be developed to ensure that the plant is capable of meeting applicable deterministic and probabilistic requirements for each plant state. Note that the plant states diagram in section 5.2 identifies BDBA as a plant state. However, only a subset of BDBAs is considered in the design. These are DECs.

The design should include the following:

- criteria for transition to normal operation following an AOO or DBA (e.g., the safety functions are provided, and the OLC limits for the operating configurations are met)

- key parameters and characteristics for operational states, including nominal values and deviations due to uncertainties and settings of instruments, controls, trips, equipment action time, or due to process fluctuations

- permissible conditions for different operating configurations (e.g., cold and pressurized) including transient time (e.g., power level of reactor or turbine, normal planned power transient rate, heat-up and cool-down rates) for the reactor facility’s operating life

- methods of transferring the plant between different operating configurations

- final safe configurations after AOOs, DBAs, and DECs

5.3.1 Normal operation

The design shall facilitate the safe operation of the plant within a defined range of parameters, with an assumed availability of a minimum set of specified support features for safety systems.

The design shall minimize the unavailability of safety systems. It shall address the potential for accidents to occur when the availability of safety systems may be reduced, such as during shutdown, start-up, low power operation, refuelling and maintenance.

The design shall establish a set of requirements and limitations for safe normal operation, including:

- limits important to safety

- constraints on control systems and procedures

- plant maintenance, testing, and inspection requirements to ensure that SSCs function as intended, taking the ALARA principle into consideration

- clearly defined operating configurations, such as start-up, power production, shutdown, maintenance, testing, surveillance, and refuelling – these configurations shall include relevant operational restrictions in the event of safety system and safety support system outages

These requirements and limitations, together with the results of safety analysis, shall form the basis for establishing the OLCs according to which the plant will be authorized to operate, as discussed in section 2.3.3 of this document.

Guidance

The design ensures that normal operations are carried out safely, thereby ensuring that radiation doses to workers and members of the public, as well as any planned discharges and releases of radioactive material from the plant, will be within the prescribed limits specified in the Radiation Protection Regulations, and will meet the requirements of section 2.1.1 of this regulatory document.

Operating configurations for normal operation are addressed by the OLCs described in section 2.3.3. These typically include:

- normal reactor start-up (from shutdown, through criticality, to full power)

- power operation, including full-power and low-power operation

- changes in reactor power, including load-follow modes (if applicable) and return to full-power after an extended period at low-power

- operation during transition between configurations, such as reactor shutdown from power operation (hot shutdown, cool-down)

- refuelling during normal operation, where applicable

- shutdown in a refuelling mode or other maintenance condition that opens the reactor coolant or containment boundary

- handling of fresh and irradiated fuel

The key parameters and unique characteristics of each operational configuration, including the specific design provision for maintaining the configuration, should be identified. The permissible periods of operation at different configurations (e.g., power level) in the event of a deviation from normal operating configurations should also be identified.

5.3.2 Anticipated operational occurrences

The design shall include provisions such that releases to the public following an AOO do not exceed the dose acceptance criterion provided in section 2.2.1.

The design shall also provide that, to the extent practicable, SSCs not involved in the initiation of an AOO shall remain operable following the AOO.

The response of the plant to a wide range of AOOs shall allow safe operation or shutdown, if necessary, without the need to invoke provisions beyond Level 1 defence in depth or, at most, Level 2.

The facility layout shall be such that equipment is placed at the most suitable location to ensure its immediate availability when operator intervention is required, allowing for safe and timely access during an AOO.

Guidance

The guidance in this subsection also covers elements common to AOO and DBA.

In accordance with the requirements of section 2.3.1 of this regulatory document for Level 2 and Level 3 defence in depth, the design should include the results of the analyses of AOOs and DBAs in order to provide a demonstration of the robustness of the fault tolerance in the engineering design and the effectiveness of the safety systems. The analysis should cover the full range of events over the full range of reactor power. The analysis should also cover all normal operating configurations, including low-power and shutdown states.

For a wide range of AOOs, the design should be such that any deviations from normal operation can be detected, and that the control systems can be expected to return the plant to a safe state, normally without the activation of safety systems. For both AOOs and DBAs, there should be high confidence that qualified systems (as identified in REGDOC-2.4.1, Deterministic Safety Analysis) can mitigate the event even when acting alone Footnote 20.

In the analysis of AOOs and DBAs for each group of PIEs, it may be sufficient to analyze only a limited number of bounding initiating events, which can represent a bounding response for a group of events. The rationale for the choice of these selected bounding events should be provided. The plant parameters that are important to the outcome of the safety analysis should also be identified. These parameters would typically include:

- reactor power and its distribution

- core component temperatures

- fuel cladding oxidation and deformation

- pressures in the primary and secondary systems

- containment parameters

- temperatures and flows

- reactivity coefficients

- reactor kinetics parameters

- reactivity worth of reactivity devices

Those characteristics of the safety systems, including the operating conditions in which the systems are actuated, the time delays, and the systems’ capacity after the actuation claimed in the design, should be specified and demonstrated to be consistent with the overall functional and performance requirements of the systems.

Additional information

Examples of AOOs may be found in:

- CNSC, REGDOC-2.4.1, Deterministic Safety Analysis Footnote 20

5.3.3 Design-basis accidents

The set of DBAs shall set the boundary conditions according to which SSCs important to safety are designed.

The design shall be such that releases to the public following a DBA will not exceed the dose acceptance criterion provided in section 2.2.1.

In order to prevent progression to a more severe condition that may threaten the next barrier, the design shall include provisions to automatically initiate the necessary safety systems when prompt and reliable action is required in response to a PIE.

Provision shall also be made to support timely detection of, and manual response to, conditions when prompt action is not necessary. This shall include responses such as manual initiation of systems or other operator actions.

The design shall take into account operator actions that may be necessary to diagnose the state of the plant and to put it into a stable long-term shutdown condition in a timely manner. Such operator actions shall be facilitated by the provision of adequate instrumentation to monitor plant status, and controls for manual operation of equipment.

Any equipment necessary for manual response and recovery processes shall be placed at the most suitable location to allow safe and timely worker access when needed.

Guidance

The design identifies the set of DBAs and associated conditions for which the reactor facility is designed. This includes such responses as manual initiation of systems or other operator actions.

See also section 5.3.2 of this regulatory document for guidance common to AOOs and DBAs.

Additional information

Examples of DBAs may be found in:

- CNSC, REGDOC-2.4.1, Deterministic Safety Analysis, Ottawa, Canada Footnote 20

5.3.4 Design extension conditions