RD-360: Life Extension of Nuclear Power Plants

Table of Contents

- 1.0 Purpose

- 2.0 Scope

- 3.0 Relevant Legislation

- 4.0 Introduction

- 5.0 Project Initiation

- 6.0 Establishing the Integrated Implementation Plan

- 7.0 Project Execution

- 8.0 Return to Service

- 9.0 Follow Up

- Glossary

- Associated Documents

- Appendix A

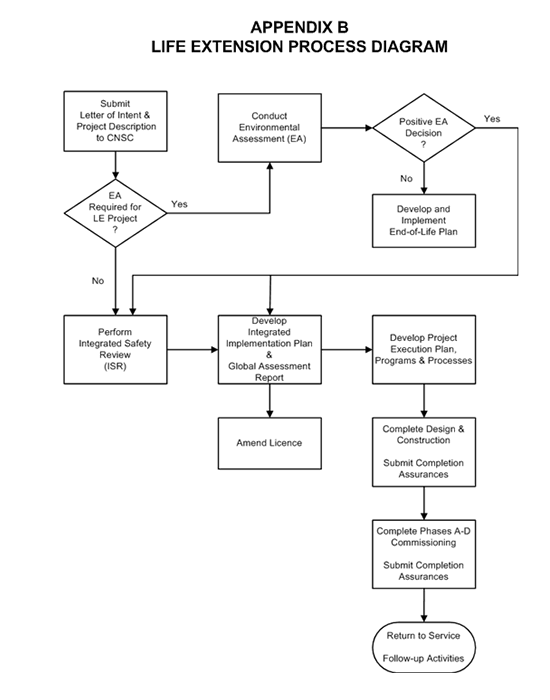

- Appendix B

1.0 Purpose

This regulatory document is one of a suite of regulatory documents that cover the life cycle of Canadian nuclear power plants from siting and design to operation and decommissioning. The purpose of this regulatory document is to inform licensees about the steps and phases to consider when undertaking a project to extend the life of a nuclear power plant (NPP).

2.0 Scope

This regulatory document addresses:

- Key elements to consider when establishing the scope of the life extension project; and

- Considerations to be taken into account in planning and executing a life extension project.

3.0 Relevant Legislation

The following provisions of the Nuclear Safety and Control Act (NSCA) and related regulations are relevant to this regulatory document:

- Section 3 of the NSCA provides for, “the limitation, to a reasonable level and in a manner that is consistent with Canada’s international obligations, of the risks to national security, the health and safety of persons and the environment that are associated with the development, production and use of nuclear energy…”;

- Section 9 of the NSCA provides the objects of the Commission, which are, “to regulate the development, production and use of nuclear energy and the production, possession and use of nuclear substances, prescribed equipment and prescribed information…”;

-

Subsection 24(4) of the NSCA stipulates that, “No licence may be issued, renewed, amended or replaced

unless, in the opinion of the Commission, the applicant

- is qualified to carry on the activity that the licence will authorize the licensee to carry on; and

- will, in carrying on that activity, make adequate provision for the protection of the environment, the health and safety of persons and the maintenance of national security and measures required to implement international obligations to which Canada has agreed”;

- Subsection 24(5) of the NSCA provides that, “a licence may contain any term or condition that the Commission considers necessary for the purposes of the Act…”;

- Section 3 of the General Nuclear Safety and Control Regulations contains the general licence application requirements;

- Paragraph 12(1)(c) of the General Nuclear Safety and Control Regulations says that every licensee shall, “take all reasonable precautions to protect the environment and the health and safety of persons and to maintain security”;

- Paragraph 12(1)(f) of the General Nuclear Safety and Control Regulations says that every licensee shall, “take all reasonable precautions to control the release of radioactive nuclear substances or hazardous substances within the site of the licensed activity and into the environment as a result of the licensed activity”;

- Paragraph 12(1)(i) of the General Nuclear Safety and Control Regulations stipulates that every licensee shall, “take all necessary measures to facilitate Canada's compliance with any applicable safeguards agreement”;

- Section 3 of the Class I Nuclear Facilities Regulations outlines the general licence application requirements specific to nuclear power plants; and

- Section 6 of the Class I Nuclear Facilities Regulations stipulates the information that is required in an application for a nuclear power plant operating licence.

Regulations associated with the Canadian Environmental Assessment Act will also be applicable to a life extension project. Other relevant legislation is listed in the Associated Documents section at the end of this regulatory document.

4.0 Introduction

Nuclear power plants in Canada are subject to the ongoing regulatory oversight of the Canadian Nuclear Safety Commission (CNSC, the Commission), including periodic licence renewal. However, the NPP licensee may choose, for the purpose of long-term operation, to implement a life extension project. Continued operation of the NPP is largely dependent on the work that will be required for long term safe operation of the plant.

A life extension project may involve the replacement or refurbishment of major components, or substantial modifications to the plant, or both. As such, these projects represent a commitment to long-term, continued operation of the facility. In keeping with the objectives of the NSCA, the Commission is mandated to ensure that facility operation continues to pose no unreasonable risk to health, safety, security, or the environment, and will conform to Canada’s international obligations.

The Commission therefore considers it to be in the public interest that licensees address modern high level safety goals, and meet applicable regulatory requirements for safe and secure long-term operation. To this end, NPP licences are amended to introduce specific licence conditions for the regulatory control of life extension projects. The licensee is expected to adhere to the requirements of the NSCA and the Canadian Environmental Assessment Act, and all associated regulations, and to all licence conditions throughout the life extension project and subsequent reactor operation.

Approval for return-to-service is contingent upon demonstration by the licensee that all licence conditions have been met.

In keeping with its regulatory mandate, the Commission expects the licensee to demonstrate that the following objectives are met for any life extension project:

- The technical scope of the project is adequately determined through a Integrated Implementation Plan that takes into account the results of an environmental assessment (EA), where required, and an Integrated Safety Review (ISR);

- Programs and processes that take into account the special considerations of the project are established; and

- The project is appropriately planned and executed.

5.0 Project Initiation

The licensee formally advises the Commission of the intention to conduct a life extension project, and submits a project description with this notification. The project description indicates the licensee’s initial understanding of the project, and includes:

- Definition of project scope and objectives;

- Status of current plant design and operation;

- Project components and structures (such as permanent and temporary structures, infrastructure, construction equipment, etc.);

- Expected project activities (such as operational phases, timing and scheduling of each phase, etc.);

- Site information (such as location, environmental features, and land use);

- Waste issues; and

- Anticipated milestones.

The project description forms the basis of the EA, and is also used as a point of reference for the project.

Information to assist the licensee in developing the project description is provided in the Canadian Environmental Assessment Agency’s publication, Preparing Project Descriptions under the Canadian Environmental Assessment Act.

6.0 Establishing the Integrated Implementation Plan

Once the licensee decides to undertake a life extension project, the licensee systematically identifies and addresses all environmental and safety concerns, and integrates them into an Integrated Implementation Plan. To do this, the licensee:

- Participates in the environmental assessment (EA) process (Section 6.1, below);

- Carries out an Integrated Safety Review (Section 6.2, below); and

- Applies the results of these assessments to establish the Integrated Implementation Plan (Section 6.3.2, below).

Since the EA and ISR may provide information relevant to each other, these assessments are done in parallel where practicable.

6.1 Environmental Assessment

In accordance with the Canadian Environmental Assessment Act, the life extension project may be subject to an environmental assessment. Where an EA is required, a decision that the life extension project will not have significant adverse environmental effects is needed prior to any licensing action being taken under the NSCA.

As the responsible authority for the conduct of the EA process, the Commission is responsible for determining whether an EA is required, and ensuring that the process is carried out appropriately.

6.2 Integrated Safety Review

The Integrated Safety Review (ISR) is a comprehensive assessment of plant design, condition, and operation. It is conducted at the time that a licensee is considering life extension of an NPP. Guidance on the ISR is found in the Periodic Safety Review of Nuclear Power Plants – Safety Guide (IAEA PSR Guide) published by the International Atomic Energy Agency (IAEA). It is referred to as an ISR due to its application of the Periodic Safety Review to the life extension project.

Performed by the licensee, the ISR involves an assessment of the current state of the plant and plant performance to determine the extent to which the plant conforms to modern standards and practices, and to identify any factors that would limit safe long-term operation. Operating experience in Canada and around the world, new knowledge from research and development activities, and advances in technology, are taken into account. This enables determination of reasonable and practical modifications that should be made to systems, structures, and components, and to management arrangements, to enhance the safety of the facility to a level approaching that of modern nuclear power plants, and to allow for long term operation.

The objectives of the ISR are to determine:

- The extent to which the plant conforms to modern standards and practices;

- The extent to which the licensing basis will remain valid over the proposed extended operating life;

- The adequacy of the arrangements that are in place to maintain plant safety for long-term operation; and

- The improvements to be implemented to resolve safety issues that have been identified.

The ISR should include:

- Conformity reviews that confirm that the NPP meets and will continue to meet the current plant-specific licensing and design basis;

- A review against modern standards and practices to assess the level of safety compared to that of modern NPPs (any shortcomings against these modern standards and practices are identified and their safety significance determined);

- Any modifications that are necessary to improve the level of safety; and

- A global assessment of plant safety for long-term operation in view of each of the ISR safety factors.

Prior to performing the ISR, the licensee prepares an ISR Basis Document, which sets out the scope and methodology for the conduct of the ISR. The ISR Basis Document includes the following information:

-

The proposed extended life of the facility

The ISR Basis Document clearly defines the full period of proposed extended operation. This information is also included in the project description if an EA is required.

-

The scope of the ISR

The safety factors to be addressed in the ISR are listed in the IAEA’s safety guide, Periodic Safety Review of Nuclear Power Plants. In addition, the scope of the ISR should at least address CNSC safety areas and programs (refer to Appendix A).

The ISR should address site-specific facilities, systems, structures, and components, and any applicable site-wide issues, such as dependencies on common services. The physical status of' each unit should be considered separately for an ISR of multiple units of the same design. The adequacy of management arrangements should also be addressed.

In addition, the ISR scope should consider, as appropriate for each safety factor, all expected modes of operation (i.e., normal operation, maintenance, refuelling, shutdown, and start-up activities), to determine whether there is any potential for increased or unacceptable levels of risk.

All generic action items and station-specific actions items should be addressed in the review, with each being resolved to the extent practicable.

-

Statement of modern standards and practices

The set of modern standards and practices that will be used in the review of each ISR safety factor should be provided, including the criteria for the selection of applicable standards and specifications.

Primary consideration should be given to CNSC regulatory documents that would apply to a new facility, as well as to standards currently referenced in licences. The licensee should also consider IAEA or other appropriate modern international standards and practices.

For each document listed, the licensee should indicate whether a high-level review, a clause-by-clause review will be performed, or whether an alternative approach will be taken. The rationale for the selected approach should be outlined.

-

Statement of the plant licensing basis at the time of initiating the ISR

The licensing basis is used in conformity reviews, and also serves as the baseline in the review against the modern standards and practices.

The licensing basis includes the CNSC regulatory framework, the documents referenced in the station-specific licence, the documents submitted by the licensee in support of the licence application, and the documents referenced therein.

-

Process for identifying and addressing gaps

The licensee describes its processes for identifying and addressing gaps between current and desired plant state and performance, documenting the significance of any gaps, and prioritizing corrective actions and safety improvements.

Non-compliance with the current licensing and design basis should be addressed immediately by the licensee. Non-compliance with modern standards and practices should be resolved to the extent practicable. An appropriate justification should be provided for any unresolved shortcomings.

The Commission reviews the ISR Basis Document for acceptance.

6.2.2 ISR Safety Factor Reports

The licensee considers all pertinent safety factors and prepares ISR Safety Factor Reports for submission to the Commission. The licensee proposes the manner in which the scope of the ISR will be addressed, and either submits reports addressing each ISR safety factor separately, or groups documentation accordingly.

The ISR Safety Factor Reports contain the review results, including proposed corrective actions and safety improvements, for the specific topics. The results of the conformity reviews and the comparison against modern standards and practices are also included.

6.2.3 Confirmation of the Adequacy of ISR Safety Factor Reports

The Commission reviews the ISR Safety Factor Reports for acceptance. The final results are incorporated in the development of the licensee’s Integrated Implementation Plan.

6.3 Global Assessment and Integrated Implementation Plan

The licensee incorporates the results of the EA and the ISR Safety Factor Reports in a Global Assessment Report, which includes an Integrated Implementation Plan.

The Global Assessment Report presents significant ISR results, including plant strengths, the Integrated Implementation Plan for corrective actions and safety improvements, and an overall risk judgment on the acceptability of continued plant operation. Interactions between safety factors, individual shortcomings, corrective actions, and safety improvements, including compensatory measures, should be considered in assessing the overall plant safety and the acceptability of continued operation. The global assessment should also show the extent to which the safety requirements of the defence-in-depth concept are fulfilled.

6.3.2 Integrated Implementation Plan

When developing the Integrated Implementation Plan, the licensee:

- Identifies a list of shortcomings for each of the safety factors identified in the ISR;

- Identifies a list of strengths with respect to fulfilling the safety requirements of the defence-in-depth concept;

- Evaluates the safety significance and ranking of each of the shortcomings and prioritizes corrective measures. Significant safety issues should be addressed immediately. Justification for proposed exemptions from the modern standards and practices should be provided, taking the safety significance, physical practicality, and other information into account, as appropriate;

- Develops corrective actions and safety improvements for each of the shortcomings, as far as practicable; and

- In view of each of the ISR safety factors, evaluates the acceptability of plant operation over the next review period in an integrated assessment.

The Integrated Implementation Plan indicates the schedule for implementing the safety improvements, which should be completed within a reasonable time frame. The licensee provides justification for deferral of the work if the safety improvements cannot be completed during the nearest outage.

The licensee updates all station documentation such as the safety analysis report, operating and maintenance procedures, and training materials to reflect the outcomes of the ISR.

Licensees may elect to submit cost-benefit information in support of the Integrated Implementation Plan.

6.4 Confirmation of the Adequacy of the Global Assessment Report

The Commission reviews the licensee’s Global Assessment Report for acceptability by assessing:

- The completeness of the assessment;

- The significance and ranking of identified safety issues for all assessed safety factors;

- The adequacy of proposed corrective actions and safety improvements, or justification of proposed exemptions;

- The adequacy of proposed implementation schedule;

- The adequacy of the proposed measures for assuring the quality of the life extension activities; and

- Conformance with the EA results.

The results of the Commission reviews are taken into account in the revision of the Global Assessment Report, including the Integrated Implementation Plan.

The Commission either accepts the Global Assessment Report, or requires changes. Upon acceptance of the Global Assessment Report, the licence is amended to include licence conditions to be met in the return-to-service phase of the project.

6.4.1 Integrated Implementation Plan Changes

The licensee should have a well defined process for the control of any changes to the Integrated Implementation Plan. Formal approval is required for:

- Changes in the plan associated with work that is needed to fulfil the requirements identified by the screening EA; and

- Changes in the plan for items subject to conditions of the operating licence.

7.0 Project Execution

7.1 Project Execution Planning

The licensee prepares a Project Execution Plan that identifies what needs to be done to achieve the desired outcomes for the project. Areas that may require special attention when planning the project execution typically include:

- Historical design issues;

- Component obsolescence;

- Resource requirements;

- Use of contractors;

- Unique or unusual plant configurations; and

- Return to service plans.

7.2 Programs and Processes

To enable project implementation, the licensee needs acceptable programs and processes to control and execute the life extension project. These programs and processes may include consideration of such areas as:

- Change control;

- Commissioning;

- Configuration management;

- Construction;

- Emergency preparedness;

- Engineering design;

- Environmental protection;

- Fire protection;

- Human factors;

- Nuclear criticality safety program;

- Occupational health and safety;

- Outage management;

- Training and personnel qualification;

- Procurement;

- Quality management;

- Radiation protection;

- Safeguards;

- Safety management;

- Security;

- Stakeholder communication;

- Waste management; and

- Work control.

The licensee should refer to Commission requirements and appropriate legislation and standards when addressing these considerations, both for guidance in their development, and to determine how program outcomes will be measured.

The adequacy of programs and processes for the control of the life extension project will be assessed by the Commission.

7.3 Project Monitoring

The licensee is expected to monitor the project for progress, safety, and quality at all phases of execution. Items to be monitored may include:

- Complete redesigns or design modifications;

- Engineering field changes;

- Installation rework;

- Procedural non-compliances;

- Plant configuration;

- Missed completion dates;

- Worker safety events involving injuries, near misses, unsafe practices, unplanned dose uptakes; and

- Environmental performance.

Project monitoring includes verifying that the work has been done correctly, and may reveal the need for:

- Creation of new programs and procedures;

- Revision of existing programs and procedures;

- Resource changes;

- Revision of existing training programs or material; or

- New training programs or material.

The licensee should assess all identified shortcomings to determine their causes and the impact of the shortcomings or their causes on other aspects of the project.

8.0 Return to Service

The licensee needs to establish a Return to Service Plan for the life extension project. Return to service involves returning the reactor, the nuclear systems, and the non-nuclear systems, back to commercial operation. Return to service includes demonstration by the licensee that all relevant licence conditions have been met and that the associated work has been done to the satisfaction of the Commission. The licensee is expected to submit design completion and construction completion assurance reports, as well as completion assurance reports for each phase of commissioning.

8.1 Commissioning Phases

Return to service is dependent on the licensee’s ability to demonstrate that new and existing plant systems, structures, and components conform to the defined physical, functional, performance, safety, and control requirements, and that management arrangements have been appropriately updated.

This is accomplished through four commissioning phases:

- Phase A: Focuses on ensuring that those systems required to ensure safety with fuel loaded into the reactor have been adequately commissioned. This phase must be successfully completed prior to loading fuel in the reactor;

- Phase B: Focuses on ensuring the fuel is loaded into the reactor safely, and confirming that the reactor is in a suitable condition to be started up and that all prerequisites for permitting the reactor to go critical have been met. This phase must be successfully completed prior to removal of the guaranteed shutdown state (GSS);

- Phase C: Focuses on confirming reactor behaviour at the stage of initial criticality and subsequent low power tests, and includes activities that cannot be done during the GSS; and

- Phase D: Focuses on demonstrating reactor and systems behaviour at higher power levels, including activities that could not be carried out at the power levels in Phase C.

System baseline data from past commissioning activities should be referenced if available, or new baseline data is established. This may include inaugural and baseline inspections of existing and newly installed systems, structures, and components. In addition, the licensee is expected to define the acceptance criteria for the commissioning tests.

8.2 Milestones

Return to service is achieved through the accomplishment of numerous milestones. Milestones that might be reflected in the return to service stage of a life extension project include:

- Loading fuel;

- Removing the guaranteed shutdown state;

- Heat transport operation;

- Turbine operation;

- Turbine synchronization to the grid;

- Full reactor power; and

- Specific commissioning tests.

8.3 Hold Points

The process of returning to service includes progressing to regulatory hold points. These hold points are typically aligned with commissioning phases, and may include the milestones listed above. Licence conditions are established for the administration of the hold points, which are then incorporated by the licensee in the Return to Service Plan.

Commission approval to remove a given hold point is contingent on licensee submission of a Completion Assurance Document. This document presents evidence that all project commitments scheduled for completion prior to removal of the respective hold point have been met. The Completion Assurance Document must be accepted by the Commission before authorization to remove the hold point can be issued.

8.4 Return to Normal Operation

Once all Commission approvals have been granted and hold points have been removed, the licensee proceeds to normal operation.

9.0 Follow Up

The licensee will be expected to monitor the adequacy of plant performance and new or updated programs after return to service.

Glossary

Design basis

The range of conditions and events taken into account in the design of the facility, according to established

criteria, such that the facility can withstand them without exceeding authorized limits for the planned operation of

safety systems.

Design life

The period specified for the safe operation of the facility, systems, structures, and components.

Environmental assessment

An assessment of the environmental effects of the project conducted in accordance with the CEAA and its regulations.

Generic action item

Unresolved safety-related issues that have been singled out by the Commission as requiring corrective actions to be

taken by the licensees within a reasonable time frame.

Guaranteed shutdown state (GSS)

A set of conditions that provide sufficient guarantee that the reactor will remain in the shutdown state despite any

credible failure.

Hold points

Specific milestones that are built into the commissioning plan to separate critical phases during commissioning, and

to allow for regulatory review before transition between phases. Hold points further enable verification of the

resolution of issues so that proceeding to the next stage will not pose unreasonable risk to health, safety,

security, or the environment.

Integrated safety review (ISR)

A comprehensive assessment of plant design and operation performed in accordance with the IAEA’s

Periodic Safety Review of Nuclear Power Plants – Safety Guide.

Licensing basis

Includes the design basis, and is the set of information that demonstrates that:

- The facility meets all applicable regulatory and safety requirements, and

- The applicant and licensee are qualified and have made adequate provisions for safe facility operation.

Life extension

Extending the safe operating life of a nuclear power plant beyond its design life. It involves the replacement or

refurbishment of major components, or substantial modifications to the plant, or both.

Modern standards

The set of high-level objectives and requirements for the siting, design, construction, commissioning, operation and

decommissioning of a nuclear power plant if it were to be built at the time of the initiation of the life extension

project.

Nuclear power plant

Any fission reactor installation constructed to generate electricity on a commercial scale. A nuclear power plant is

a Class IA nuclear facility, as defined in the Class I Nuclear Facilities Regulations.

Practices

The information contained in modern industrial standards, codes, and practices directly associated with the modern

standards. Guidelines should take into account operating experience and findings from technical developments (e.g.,

new knowledge on the cumulative effects of ageing, results of reactor physics research and development, human

factors engineering, human reliability, software engineering).

Prescribed

Means prescribed by federal regulations.

Refurbishment

An activity or a set of activities aimed at restoring the condition of one or several systems to a state that is

comparable to the condition of a new system.

Associated Documents

- Nuclear Safety and Control Act, S.C. 1997, c. 9;

- Packaging and Transport of Nuclear Substances Regulations, SOR/2000-208, May 2000;

- Radiation Protection Regulations, SOR/2000-203, May 2000;

- Nuclear Security Regulations, SOR/2000-209, May 2000;

- Nuclear Non-proliferation Import and Export Control Regulations, SOR/2000-210, May 2000;

- Nuclear Substances and Radiation Devices Regulations, SOR/2000-207, May 2000;

- Canadian Nuclear Safety Commission Rules of Procedure, SOR/2000-211, May 2000;

- CNSC Regulatory Standard S-99, Reporting Requirements for Operating Nuclear Power Plants, March 2003;

- CNSC Regulatory Policy P-242, Considering Cost-benefit Information, October 2000;

- Canadian Nuclear Safety Commission - Guidelines for Environmental Assessment pursuant to the requirements of the Canadian Environmental Assessment Act, Revision 2, December 2004;

- Nuclear Liability Act, R.S.C., 1985, c. N-28;

- Canadian Environmental Assessment Act, S.C. 1992, c. 37;

- CEAA Exclusion List Regulations, SOR/94-639;

- CEAA Inclusion List Regulations, SOR/94-637

- CEAA Comprehensive Study List Regulations, SOR/94-638;

- Procedures for an Assessment by a Review Panel, guidelines issued pursuant to the CEAA, November 1997;

- Preparing Project Descriptions under the Canadian Environmental Assessment Act, Canadian Environmental Assessment Agency, August 2000;

- CEAA Law List Regulations, SOR/94-636, October 1994;

- Canadian Environmental Protection Act, S.C. 1999, c. 33;

- Nuclear Fuel Waste Act, S.C. 2002, c. 23;

- Fisheries Act, R.S.C., 1985, c. F-14;

- Species at Risk Act, S.C. 2002, c. 29;

- Migratory Birds Convention Act, S.C. 1994, c. 22;

- Canada Water Act, R.S.C., 1985, c. C-11; and

- Periodic Safety Review of Nuclear Power Plants—Safety Guide, Safety Standards Series No. NS-G-2.10, IAEA, Vienna, 2003.

Appendix A

CNSC Safety Areas |

CNSC Programs |

|---|---|

1. Operating Performance |

1. Organization and Plant Management 2. Operations 3. Occupational Health and Safety (non-radiological) |

2. Performance Assurance |

1. Quality Management 2. Human Factors 3. Training |

3. Design and Analysis |

1. Safety Analysis 2. Safety Issues 3. Design |

4. Equipment Fitness for Service |

1. Maintenance 2. Structural Integrity 3. Reliability 4. Equipment Qualification |

5. Emergency Preparedness |

1. Emergency Preparedness |

6. Environmental Performance |

1. Environmental Protection Systems 2. Effluent and Environmental Monitoring |

7. Radiation Protection |

1. Personnel Exposure 2. Plant Waste Management |

9. Safeguards 1 |

1. Safeguards |

Page details

- Date modified: